Aluminium Composite Panel (ACP) is a type of flat panel that consists of two thin aluminium sheets bonded to a non-aluminum core. ACP is used within the signage industry as an alternative to heavier, more expensive substrates. ACP is also used for external and internal architectural cladding or partitions, false ceilings, machine coverings, container construction, etc Composition and function As a new type ...

Parameters of aluminum sheet plate for license plate Alloys: 1050, 1060, 6061 etc Temper: HO, H14, T6 etc Sizes: 6" 12" ( 12'' x 6'', 6x12 inch ), 10x5 ( 5"x10" ) etc Surface treatment: Anodized, color coated etc Application Aluminum plain license plates can be used in many places for stamped street traffic signs, laser cutting house door number sign, CNC embossing number metal aluminum logo automot ...

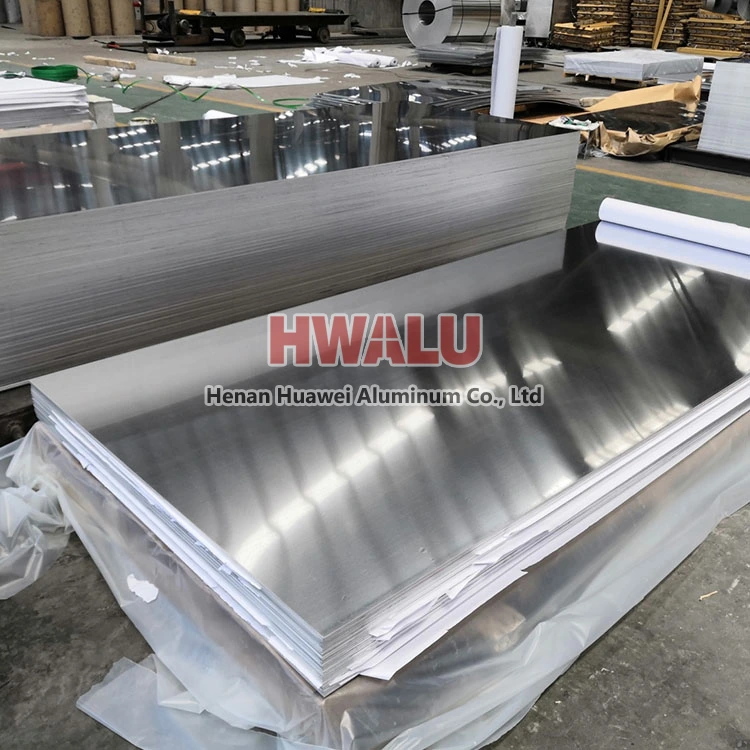

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

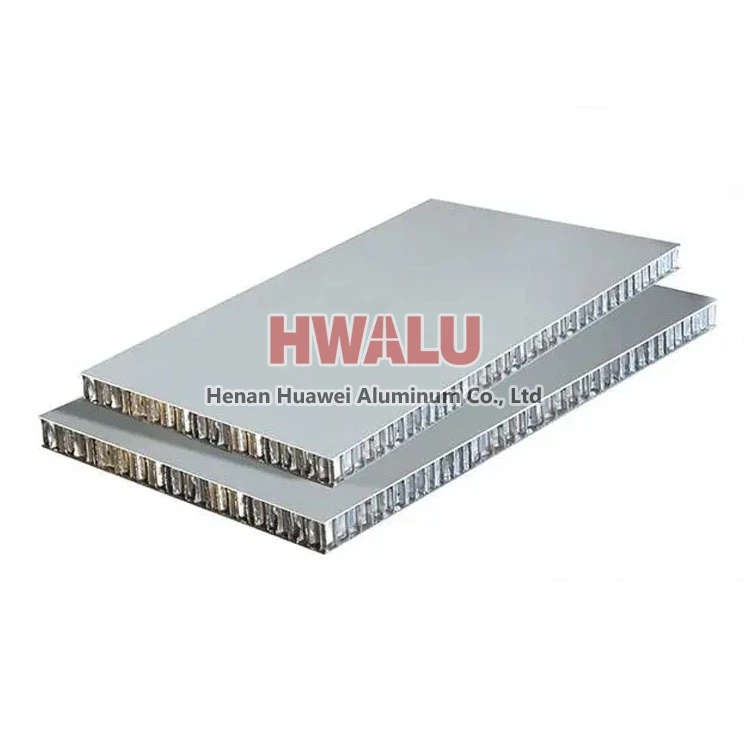

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

1. Current Situation of Aluminum Sheet in Automotive Field In the whole auto industry, the theme of energy conservation and environmental protection is becoming more and more popular, the application prospect ofAluminum Sheet in automotive fieldis generally seen to be positive.Aluminum Sheet in automotive field is light in weight and has the feature of wear resistance, good appearance, good formability, high s ...

5083 aluminum sheet is a high strength material, exhibiting higher strength than 5052 sheet.5083 H116 is an alloy used for high strength welded applications, with excellent marine environment corrosion resistance. It has a superior “skin finish” developed to prevent skin lamination, thus providing even better resistance to inter-granular corrosion than alloy 5083 H321. It has higher Tensile and Yield strengths th ...

Material Notes: Same nominal composition but higher Si and Fe impurity limits than Al-5657 Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN. Composition Notes: Composition information provided by the Aluminum Association and is not for design. Key Words: UNS A95005; ISO AlMg1; Aluminium 5005-H34; AA5005-H34; Al5005-H34 5005 h34 aluminum sheet Availabl ...

The processing cost of aluminum sheet and foil mainly includes the cost of natural gas, electricity, auxiliary materials, machinery depreciation, management expenses and so on. Natural gas is mainly used in the melting process of aluminum coil. The fuel consumption of liquid aluminum coil processing is 60 cubic meters per ton. The processing cost of a ton of aluminum coil in Henan increased by 114 yuan, and that ...

The 7000 series aluminum sheet is the best series of eight aluminum alloy series, representing the highest level of current aluminum sheet production process. The most representative product of the 7000 series aluminum can be said 7075 aluminum sheet, which has high strength and high hardness. The main alloying elements of the 7000 series aluminum sheet are zinc and magnesium. As a cold forging alloy, the stre ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...