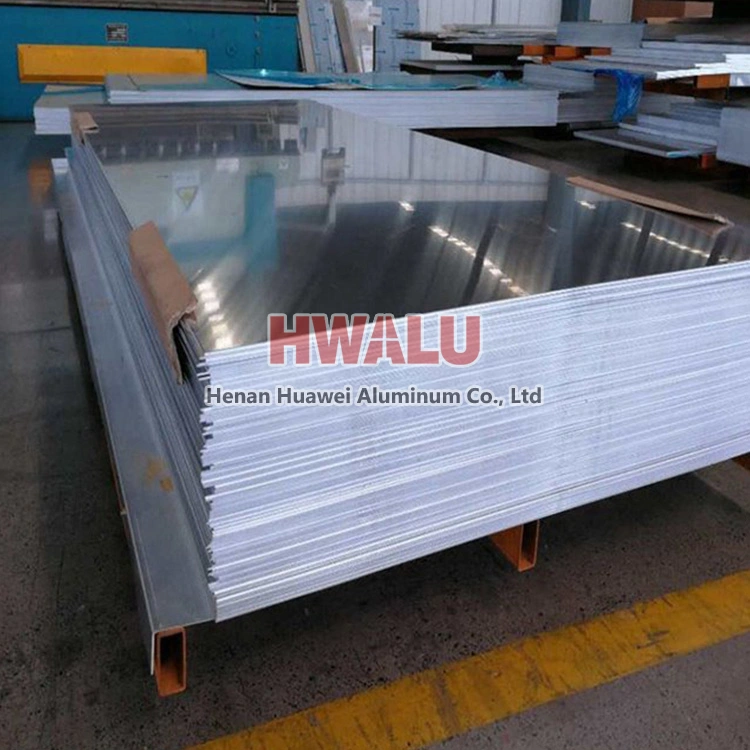

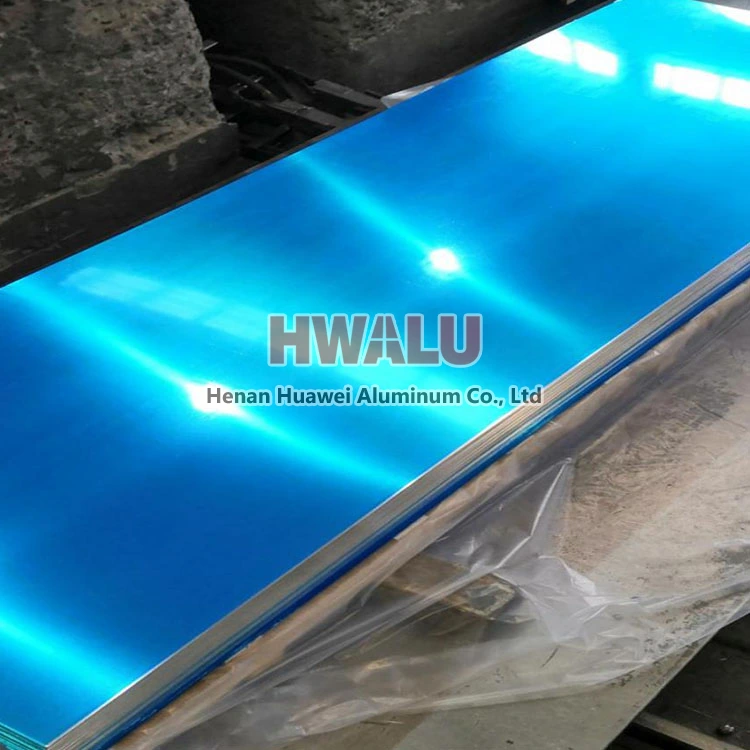

Aluminum sheet plate

Aluminum sheet plate refers to the rectangular plate made by rolling aluminum ingot, or the plate aluminum products made by heating, rolling, straightening or solid solution aging heat of flat aluminum embryo.

Aluminum plate refers to aluminum material with a thickness of 0.2mm to 500mm, a width of 200mm or more, and a length of 16m or less.It is called aluminum sheet or aluminum sheet. With the progress of large equipment, there are more aluminum plates up to 600mm wide).

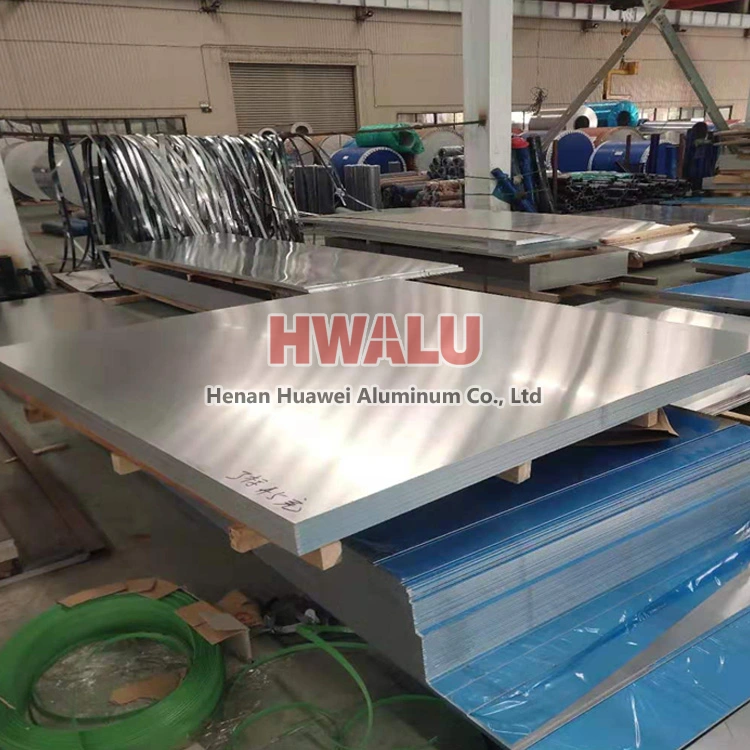

We can custom aluminum sheet by customer’s requirement, such as alloy temper, size, thickness etc

Aluminum plate is mainly used for lighting, solar reflector, architectural appearance, ceiling, furniture, cabinets, elevators, signs, nameplates, luggage, interior and exterior decoration of automobiles, refrigerators, microwave ovens, audio equipment, aerospace and military aspects.

Henan Huawei Aluminum Co., ltd

We are a Chinese leading aluminium product manufacturer located in the capital of Henan Province, P.R. China. It takes 25 minutes to Zhengzhou International Airport from our company.

Product quality was perfectly guaranteed by our long-term experience in this line.

Personnel & Concept:

We have 1600 employees, including 87 senior technicians and 28 professionally skilled workers. Our company is persisting in the enterprise concept of “Customers are the foundation of us, Technique are the life of us”. We insist on serving our customers with the best service and the most competitive quality.

We can produce aluminum products by customer’s requirements, and our products mainly includes aluminum sheet, aluminum coil, aluminum foil, aluminum strip, round aluminum circle, aluminum tread plate, embossed aluminum, mirror aluminum, anodized aluminum, color coated aluminum, heat transfer plates, and other aluminum machining parts, blister foil etc

News

Aluminum is a common light metal with many unique properties, one important of which is its relatively low melting point. First, we need to understand the basic properties of aluminum. Aluminum has an atomic number of 13 and an atomic weight of 26.98. It is silvery white, soft, malleable, and conductive. Aluminum has a melting point of 660.32°C, which is lower than many other metals such as iron and copper. ...

The definition of aluminum plate density Density refers to the ratio of mass to volume of an object, usually expressed in grams per cubic centimeter. The density of the aluminum plate refers to the mass of the aluminum plate per unit volume, that is, the ratio of the mass to the volume of the aluminum plate. The density of the aluminum plate is closely related to the composition of the aluminum alloy, the manufa ...

Features Honeycomb Aluminum Panel Composite aluminum plate Material Aluminum plate and aluminum honeycomb core Aluminum sheet and non-metallic core material (e.g. polyethylene) Thickness The thickness is generally 6mm, 10mm, 15mm, 20mm, etc. The thickness is generally 3mm, 4mm, 5mm, etc. Weight Lightweight, generally 5kg/m2-7.5kg/m2 Relatively heavy, generally 8kg/m2-12kg/m2 ...

Thickness and usage vary. The thickness of the thin aluminum sheet is between 0.2mm and 6.0mm, while the thickness of the thick aluminum plate is above 6.0mm. Because of its relatively thin thickness, the thin aluminum sheet is often used in applications that require lightweight, high strength, and good electrical conductivity, such as electronics, automotive, aerospace, and construction. The thickness of t ...

Alloy 2024 T3 Aluminum Sheet is a high-strength, corrosion-resistant aluminum alloy material commonly used in the manufacture of the aerospace industry, automobile manufacturing, shipbuilding, and other applications that require lightweight, high-strength materials. Among them, "2024" means that the main components of the alloy are aluminum, copper and magnesium, and T3 means that the material has undergone a ...

Brinell hardness test method: This is a commonly used metal hardness test method, which is applicable to various metals and alloys. This method uses a steel ball or drill bit with standard geometric shape and size, presses a certain load on the aluminum plate to be tested, and determines the hardness value according to the indentation depth. The hardness value of aluminum plate is usually expressed in Brinell ...