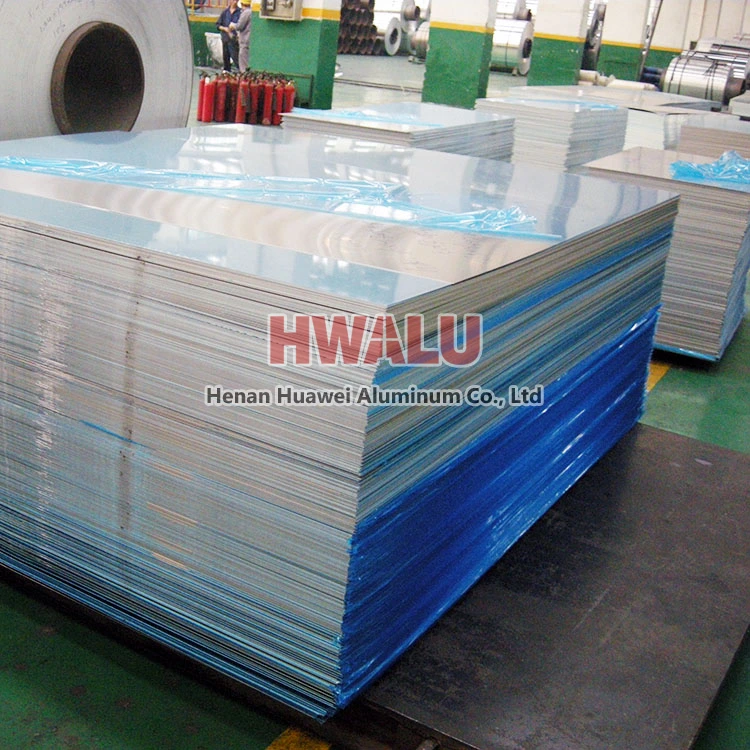

The most typical use of aluminum sheet for wall is aluminum curtain wall. The aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plates. Its common thickness is 1.5, 2.0, 2.5, 3.0MM, the model is 3003, and the state is H24. wall sheet Parameters of aluminum plain sheet plates for wall There are generally four thicknesses of curtain wall aluminum veneer: 1mm thickness, ...

Overview of 5083 Alloy Thin Aluminum Sheet 5083 alloy metal aluminum sheet plate belongs to Al-Mg-Si 5000 series aluminum sheet. Its main contents are Magnesium and Silicon except for Aluminium. Over 4.0% of Magnesium enables 5083 aluminium plates to have excellent resistance to correction, and easily to welded. By adding cooper, 5083 aluminum plate has 28% Electrical conductivity. 5083 aluminum plate also has g ...

Construction with aluminum veneer where to buy? Why do architects prefer anodized aluminum? ① Good processability: anodized aluminum plate decorative strong, moderate hardness, easy bending molding, continuous high-speed stamping, convenient direct processing into products, no need to carry out complex surface treatment, greatly reduce the production cycle and reduce product production costs. (2) Good wea ...

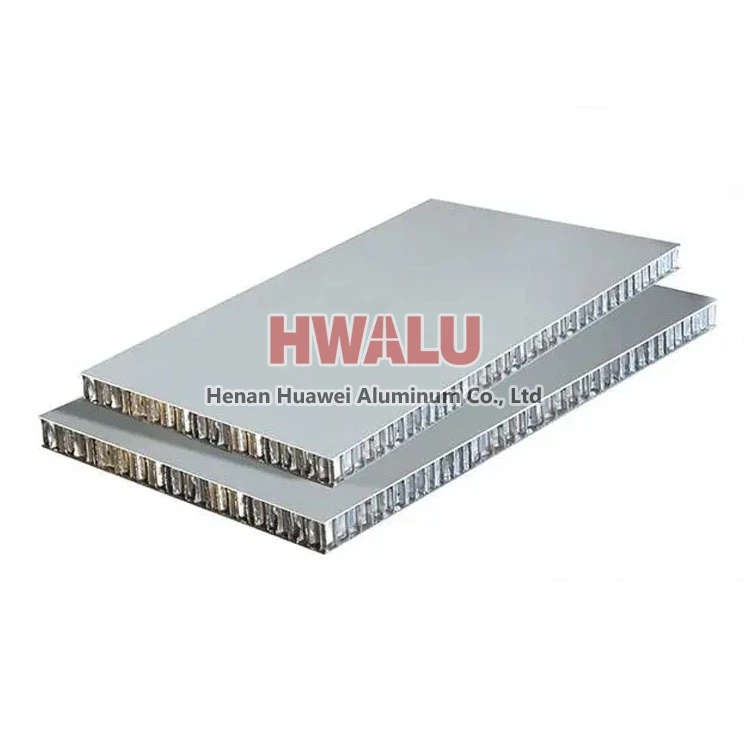

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

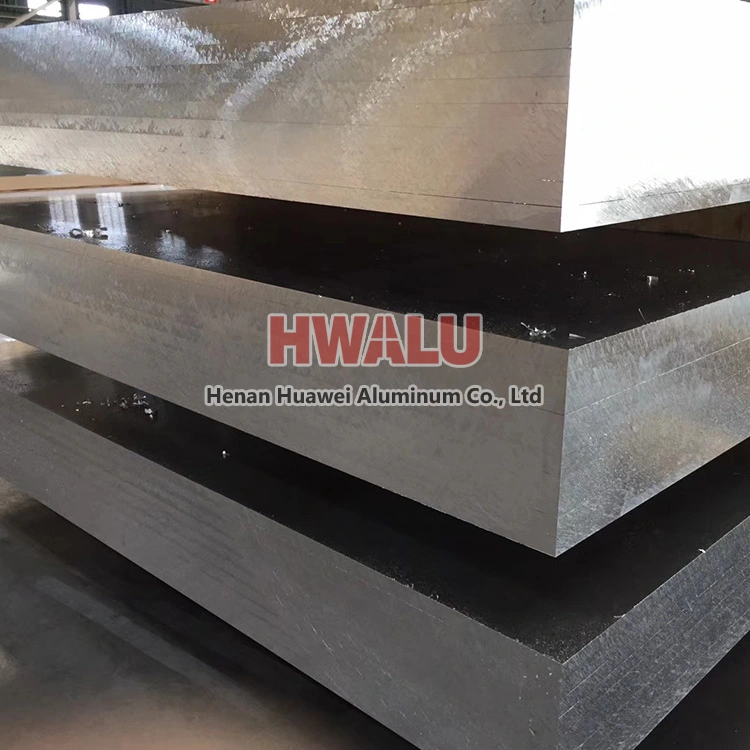

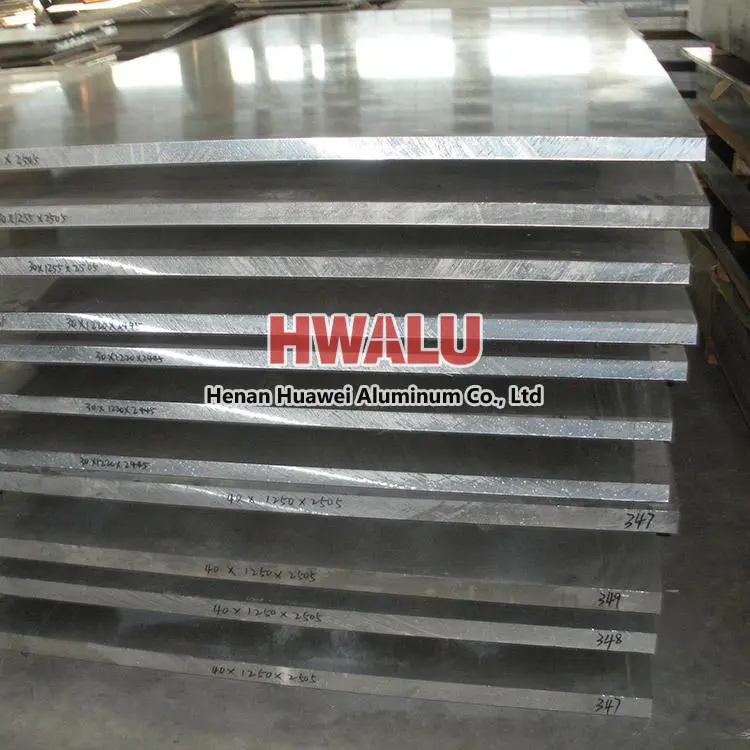

What is hot rolling? Hot rolling generally refers to rolling above the recrystallization temperature of the metal. During the hot rolling process, the metal deformation has both hardening and softening processes. Due to the influence of the deformation speed, as long as the recovery recrystallization process is too late, the metal will have a certain degree of work hardening with the increase of the deformation ...

what is Aluminum corrugated sheet? Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold- ...

3004-O aluminum is 3004 aluminum in the O temper. To achieve this temper, the metal is strain hardened, and then stabilized, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H38). It has the second highest ductility compared to the other variants of 3004 aluminum. The graph bars on the material properties cards below compare 3004-H32 aluminum to: 3000-series alloys (top), all ...

The definition of aluminum plate density Density refers to the ratio of mass to volume of an object, usually expressed in grams per cubic centimeter. The density of the aluminum plate refers to the mass of the aluminum plate per unit volume, that is, the ratio of the mass to the volume of the aluminum plate. The density of the aluminum plate is closely related to the composition of the aluminum alloy, the manufa ...

Aluminum 3105 alloy sheet has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2 t range for annealed H12, H14 and H16 tempers. Bend radii of 2 to 7 t should be used for the H18 temper. Due to its physical properties aluminum sheet & plate is valued and sought after choice metal for many different industrial applications, some of which include: Roofing Gutter ...

Aluminum alloy 3105 is essentially a 98% aluminum alloy with minor additions to increase strength over that of alloy 1100 and 3003. It is not hardenable by heat treatment and it has good corrosion resistance, formability and weldability. Typical applications include general sheet metal work requiring greater strength than is provided by 1000 series aluminum alloys, residential siding, mobile homes and sign making ...

6063 Aluminum sheet is widely used in frame construction aluminum doors and windows, curtain walls, in order to ensure the high wind resistance performance, assembly performance, corrosion resistance and decorative properties, the comprehensive performance requirements of the Aluminum Alloy is much higher than the industrial standard. 6063 alloy has lower strength than 6061 alloy, it is with good extrusion, co ...

7075-T6 Aluminum Sheet is primarily used in aerospace industry, often referred to as the Strongest Aluminum grade. Alloy 7075 has the strength of many steels, while retaining aluminum’s lightweight qualities. 7075 aluminum sheet is one of the highest strength aluminum alloys available Its strength-to weight ratio is excellent and it is ideally used for highly stressed parts. It may be formed in the annealed co ...