Construction with aluminum veneer where to buy?

Why do architects prefer anodized aluminum?

① Good processability: anodized aluminum plate decorative strong, moderate hardness, easy bending molding, continuous high-speed stamping, convenient direct processing into products, no need to carry out complex surface treatment, greatly reduce the production cycle and reduce product production costs.

(2) Good weather resistance

Anodized aluminum plate with standard thickness oxide film (3μm) has no discoloration, corrosion, oxidation and rust in indoor use for a long time.

Anodized aluminum plate with thickened oxide film (10μm) can be used outdoors, can be exposed to sunlight for a long time without discoloration.

Indoor and outdoor architectural aluminum panels

③ Strong metal feeling: the anodized aluminum plate surface hardness is high, up to gemstone grade, good scratch resistance, no paint cover on the surface, retain the metal color of aluminum plate, highlight the modern metal feeling, improve product grade and added value.

④ High fire resistance: pure metal products, surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gas, meet the requirements of fire protection and environmental protection.

Aluminum plate for construction

⑤ Strong stain resistance: no handprints, there will be stains, easy to clean, do not produce corrosion spots.

⑥ Strong applicability: wide use, suitable for metal aluminum ceiling, curtain wall aluminum panel, aluminum plastic panel, fireproof board, honeycomb aluminum panel, aluminum veneer, electrical panel, cabinet panel, furniture panel and so on.

Parameters of aluminum sheets plate for building construction

Alloys: 1050, 3003 etc

Temper: H24 etc

Thickness: 1.5mm, 3mm etc

Sizes: 4ft x 8ft, 5ft x 10ft ,4ft x 10ft,etc

Overview of aluminum sheet for construction

Aluminum sheets for construction products are easy to cut, shape and manufacture. The aluminum material does not rust or corrode and is ideal for roof repairs, art and craft applications, and countertops

-

- For roof repairs or countertops

- Used indoors and outdoors

- Reduce the risk of injury by smoothing sharp edges with a file or emery cloth

- Rust and corrosion resistance

- Connect to other materials using sheet metal screws or rivets (not included)

- Aluminum structure, polished

- 0.019 inch thick

- Cut easily with tin scissors (not included)

Advantages of Aluminum sheet/plate for building:

1) Long service life, the average service life of an aluminum alloy template can reach 300-500 times

2) All structures are assembled by aluminum alloy plate. After assembly, the whole frame is formed, with good stability and high bearing capacity

3) Realize the integrated design of the top mold and support system, and integrate the early demolition technology into the roof support system, which greatly improves the formwork turnover

4) Aluminum plate support rod is relatively small, the site operation space is large, the personnel is smooth, the material handling is convenient, greatly improving the site management efficiency

5) After the removal of the aluminum alloy plate system, the concrete surface quality is smooth and smooth to achieve the effect of plain concrete

6) Wide range of applications, suitable for housing construction, housing, infrastructure, channels and tunnels, etc.

Applications of aluminum sheet plates for buildings

ACP ( aluminum composite panel ), ACM ( aluminum cladding materials ), doors ( front doors ) home facade curtain wall, sandwich sheeting for house, decorative build exterior wall aluminum plate for decoration, super flat aluminum cladding plate for ceiling panels, building cladding designs using aluminium plates, roof etc

Common uses

What are the application areas of anodized aluminum plate for building?

Architectural aluminum panels for art galleries

Aluminum panels for exterior walls

Aluminum plate for railway station ceiling

Aluminum panels for interior roof walls

Aluminum plate for refrigerator air duct

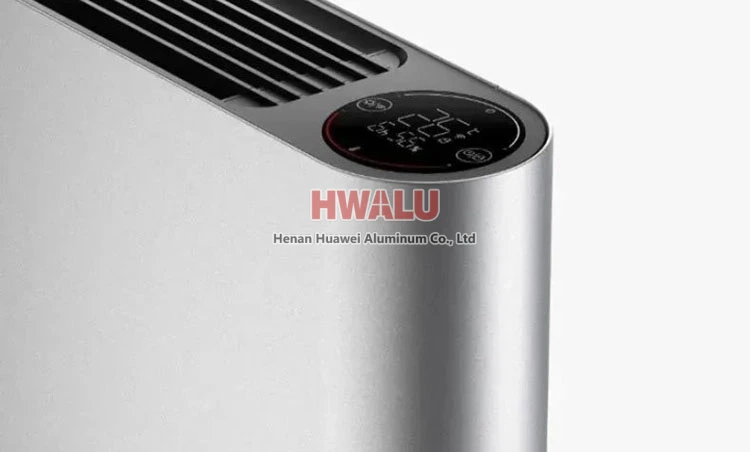

Aluminum sheet for heating fan

HUAWEI Aluminum construction aluminum plate sales area?

Malaysia, Bangladesh, Saudi Arabia, Uzbekistan, the Philippines, Taiwan, Algeria, Egypt, Italy, Peru, Brazil, Nigeria, Britain, Poland, Ghana, Albania, Vietnam, Thailand, South Korea, Mexico, Indonesia, United Arab Emirates, Colombia, India, France, South Africa, Singapore, Pakistan, Tunisia, Canada, Ecuador, and so on

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;