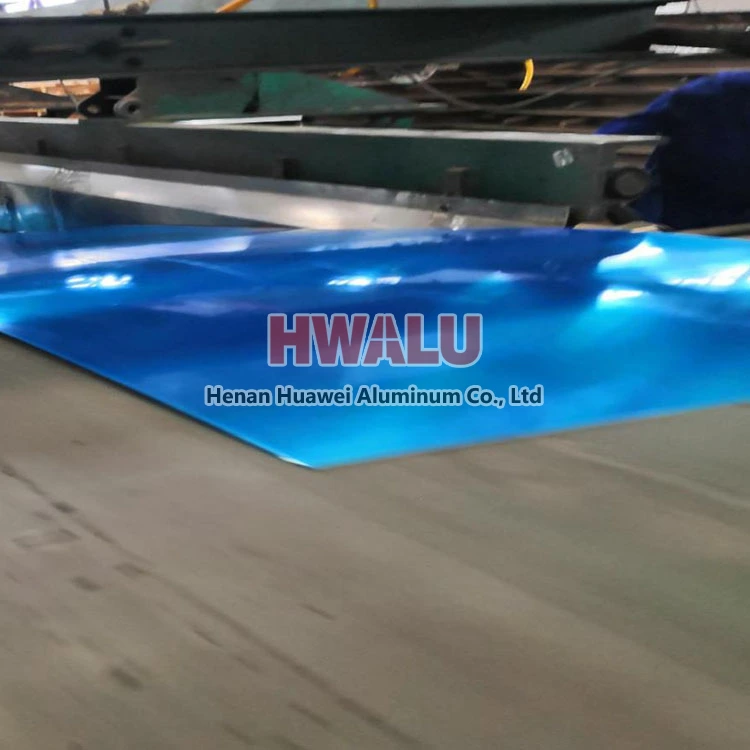

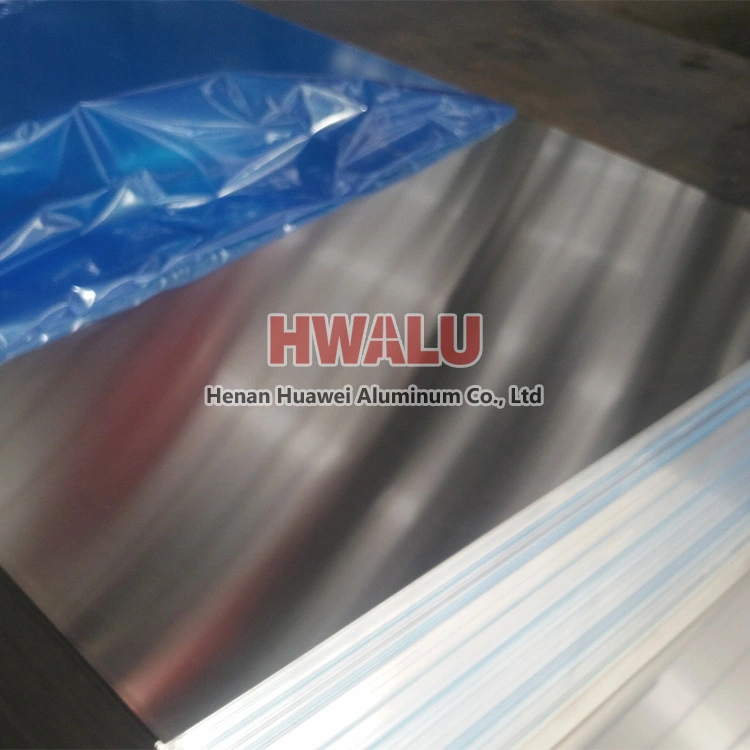

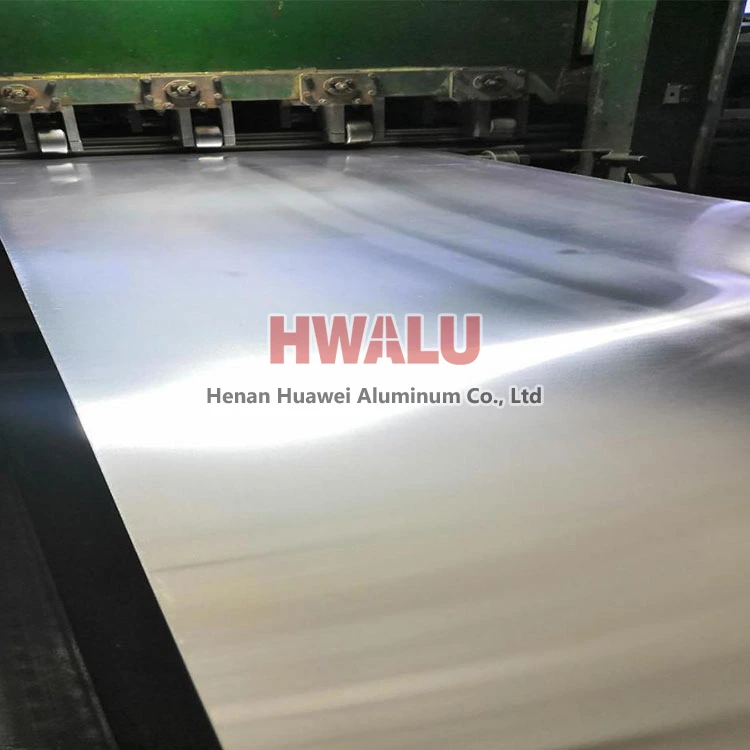

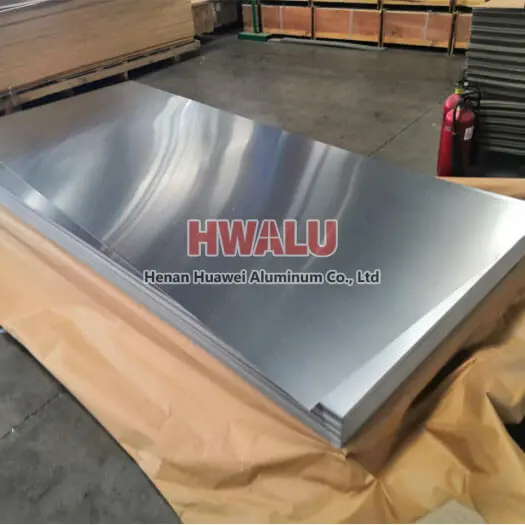

Standard thickness aluminum sheet refers to aluminium sheets with thick between 2mm ~ 6mm. Hot sale thicknesses Unit ( mm ): 2mm, 2.4mm, 2.5mm, 2.6mm, 3mm, 3.2mm, 3.5mm, 4mm, 5mm, 6mm ( thick ) etc Unit ( guage ): 11, 10, 9, 8 ga etc Hot sale size 4x8 ( 2440 x 1220, 4x8ft ), 3mmx1mx1m etc Hot sale alloy temper 1100 ( a1100 ), 3003, 5052 H32, 5053 H38, 5086, 6061 T6, 7075 etc Application So ...

Introduction of 5086 aluminum sheet 5086 alloy metal aluminum sheet plate - an aluminum alloy with the primary alloy element being magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material. Since heat treatment doesn't strongly affect the strength, 5086 can be readily welded and retain most of its mechanical strength. The go ...

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

aluminum 6061-t651 material properties 0.75" 6061-T651 is the main alloy of 6061 alloys. It is a high-quality aluminum alloy product produced by heat treatment and pre-drawing process. Although its strength cannot be compared with the 2XXX series or 7XXX series, it has many magnesium and silicon alloy characteristics, such as excellent machining performance, excellent welding characteristics, electroplating, goo ...

Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

Welcome to Huawei Aluminum, your premier destination for high-quality '032 aluminum sheet' products. Our dedication to excellence in manufacturing and supplying aluminum sheets has made us a leading name in the industry. The '032 aluminum sheet' is versatile, durable, and widely used across various industries, including automotive, construction, aerospace, and more. About '032 Aluminum Sheet' The '032 aluminum ...

what is 3003 aluminum sheet? 3003 alloy metal aluminum sheet plate is approximately 20% stronger than 1100 series aluminium. 3003 alloy is readily formed by either conventional cold working or hot working. We offer high-quality 3003 flat aluminum sheet plate and tread plate covered by the ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547. The 3003-H14 is a softer, more formabl ...

1100 aluminum sheet is pure aluminum plate series, it is with excellent ductility, formability, weldability and corrosion resistance. Anodizing can improve the corrosion resistance further, while obtaining a beautiful surface. But it has poor strength and can not through heat treatment. 1100 aluminum alloy has high electrical conductivity and thermal conductivity, low density and good plasticity. Aluminium 1100 i ...

16 gauge aluminum sheet metal thickness "gauge" is one of the units for expressing the thickness of the aluminum alloy gauge is expressed in inches: 16 gauge = 0.0508 inches Gauge is expressed in millimeters: 16 gauge = 1.29032 mm The gauge is expressed in feet: 16 gauge = 0.004233ft Aluminum sheet 16 gauge is also one of the hot selling sheet thicknesses. Note: The larger the gauge value ...

The 7075 aluminum sheet is a product that is frequently used because of its strength, toughness and corrosion resistance. It is in fact one of the strongest aluminum alloys out there. Its weight-to-strength allows it to be used for high stressed parts. In the annealed condition, the 7075 aluminum can be formed using heat methods. It’s not good with cold working. Once formed, it’s recommended that heat treatment b ...

3105 aluminum sheet alloy is AL-Mn series , good rust resistance, good electrical properties, the aluminum content of 98%, due to the addition of copper element 0.3% in which it conductivity can reach 41%; the 3105 aluminum sheet can enhance heat treatment, so the use of cold processing methods to improve its mechanical properties in annealing state the plastic is very high, in the semi-cold hardening plastic pla ...

Aluminium Alloy 2024 T4 Sheets are widely used for a majority of the reasons. Its cheap, light-weight, and high performance are the main reasons for its widespread use. It is chemically resistive, non-sparking, electrically conductive, reflective, thermally conductive, non-magnetic. It is implemented in the marine and aerospace industries, construction, electronic enclosures, aircraft, and spacecraft. Aluminiu ...