aluminum 6061-t651 material properties 0.75″

6061-T651 is the main alloy of 6061 alloys. It is a high-quality aluminum alloy product produced by heat treatment and pre-drawing process. Although its strength cannot be compared with the 2XXX series or 7XXX series, it has many magnesium and silicon alloy characteristics, such as excellent machining performance, excellent welding characteristics, electroplating, good corrosion resistance, high toughness, no deformation after processing, material density without defects, easy polishing, easy coloring film, excellent oxidation effect, etc

al6061 t651

Parameters of 0.75 aluminium 6061-t651

Alloy Composition

|

|

Al |

Mg |

Si |

Fe |

Cu |

Cr |

Zn |

Mn |

Ti |

Residuals |

| 6061-T651 |

95.9 – 98.6 |

0.8 – 1.2 |

0.4 – 0.8 |

≤0.7 |

0.15-0.4 |

0.04-0.35 |

≤0.25 |

≤0.15 |

≤0.15 |

≤0.15 |

Mechanical Properties

|

|

Brinell Hardness |

Elongation at Break |

Poisson’s Ratio |

Shear Strength |

Tensile Strength: Yield (Proof) |

Elastic (Young’s, Tensile) Modulus |

Fatigue Strength |

Shear Modulus |

Tensile Strength: Ultimate (UTS) |

| 6061-T651 |

93 |

11 % |

0.33 |

210 MPa |

270 MPa |

69 GPa |

95 MPa |

26 GPa |

320 MPa |

0.75″ 6061-T651 Aluminum Plate Hot Sale Size

Size:4*8, 4*10,4ft x8ft, 4ft x 10ft,4 foot × 8 foot,4foot × 10 foot, 4′ x 8′, 4′ x 10′, 4*8ft, 4*10ft,8×4,10×4, 8ft x 4ft,10ft x 4ft, 8 x 4 ft, 10 x 4 ft,8′ x 4′,10′ x 4′, 48″x96″, 1219mm × 2438mm, 1220mm × 2440mm ,8″ x8″(8 x8 in.),12″ x12″(1 x1 ft.),12″ x24″(1 x2 ft.),12″ x36″(1 x3 ft.),12″ x48″(1 x4 ft.),18″ x18″(18 x18 in.),24″ x24″(2 x2 ft.),24″ x36″(2 x3 ft.),24″ x48″(2 x4 ft.),36″ x36″(3 x3 ft.),36″ x48″(3 x4 ft.),48″ x48″(4 x4 ft.),48″ x144″(4 x12 ft.) etc.

What is the difference between AL6061-T6 and AL6061-T651?

The difference between T6 and T651 is that, in general, T6 has greater internal stress and will deform during machining. The most suitable state for machining should be T651, which is stretched on the basis of T6 to eliminate internal stress

6061-T6 state: cooling after solution heat treatment to achieve high strength no longer cold working

6061-T6511 status: Solution heat treatment after cooling to achieve high strength, then correction straightening process

6061-T651 state: cooling after solution heat treatment to reach high strength, and then cold drawing by drawing machine to eliminate residual internal stress after heat treatment, to ensure the accuracy of machined products, no deformation after further processing.

Typical use of 0.75 aluminum 6061 t651 plate

- Aviation device

- The truck

- Tower building

- The ship

- The pipe

Typical use of aluminum 6061 t651 plate

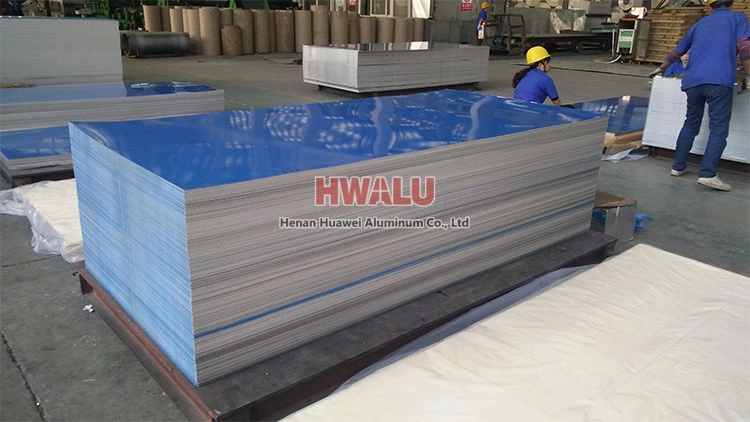

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;