What is diamond aluminum sheet?

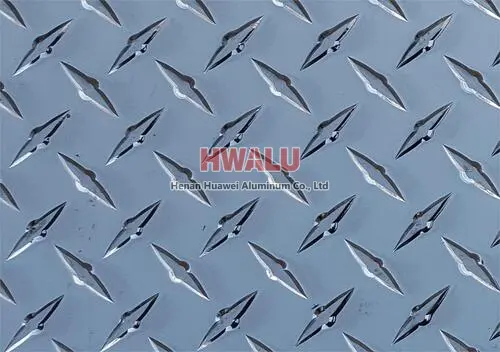

Diamond aluminum plate, also known as diamond plate or diamond pattern plate, is an aluminum plate with a raised diamond pattern on one side. The diamond-shaped aluminum plate pattern provides increased traction and durability, making it ideal for applications where slip resistance is important, such as industrial floors, stairs, ramps and truck beds.

diamond-plate-aluminum-sheet

diamond-plate-aluminum-sheet

Aluminum diamond sheet color supply

Huawei Aluminum Sheet is available in a variety of colors so you can find the perfect aluminum diamond plate sheet to suit your needs.

Highly polished diamond plate aluminum sheets: Highly polished diamond plates have high mirror luster and surface finish.

Black diamond plate aluminum sheet: Create a more modern, cleaner look with a dark, smooth, glossy aluminum sheet

black-diamond-aluminum-sheet

black-diamond-aluminum-sheet

Diamond plated aluminum sheet: has a less shiny, more industrial look and finish

Race diamond tread aluminum sheet: The red finish has a more attractive color.

What is the price of aluminium diamond sheet?

Diamond Aluminum Sheet prices may vary based on a variety of factors, including thickness, size, quality, suppliers, and market conditions. The price of aluminum diamond sheets is typically affected by raw material costs, production processes, transportation, and supply and demand dynamics. The price per ton is about 2880$/Ton

Diamond plate aluminum sheets production process

Diamond aluminum plate is a high-end building decoration material with the characteristics of steel strength, aluminum lightness and diamond texture. It is widely used in various high-end buildings, interior decoration, automobile industry and other fields.

The manufacturing process of diamond aluminum plates is a complex process, and Huawei Aluminum is able to control quality in every production step.

Diamond aluminum sheet process brief description

1. Preparation of raw materials.

The main raw material of diamond aluminum plate is aluminum alloy plate, which usually uses high-quality and high-hardness aluminum alloy materials such as 3003, 3004, 5005, 5052, 5251,5754, and 6061.

2. Diamond pattern production.

The uniqueness of the diamond aluminum plate lies in the diamond pattern on its surface. The key to producing this pattern is the design and production of the mold. The diamond pattern is cut on the aluminum plate using a CNC machine to obtain the desired shape and size.

3. Surface treatment.

The surface of the diamond aluminum plate is processed through multiple processes to ensure that its surface is flat, smooth and durable. First, the aluminum plate is pickled to remove oxide scale and impurities on the surface. Then, the surface finish and brightness of the aluminum plate are further improved through processes such as mechanical polishing and electrolytic polishing. Finally, a layer of fluorocarbon coating is applied to the surface of the aluminum plate through oxidation, electrophoresis or plastic spraying to increase its corrosion resistance and wear resistance.

4. Forming of diamond aluminum plate.

The aluminum plate is cut and bent into a diamond aluminum plate with a specific shape and size. This process is often precisely controlled via CNC machines to ensure the accuracy and consistency of the diamond aluminum sheets.

5. Decoration of diamond aluminum plate.

Diamond aluminum plates can be personalized and decorated by engraving, printing and painting. Patterns, patterns or text can be engraved on the surface of the aluminum plate according to customer needs.

Finally, the packaging and shipping of diamond aluminum sheets. After completing the production of diamond molybdenum plates, they are packaged, usually in wooden boxes or pallets, to ensure the integrity and safety of the diamond aluminum plates.

What is the use of aluminum diamond sheet?

Aluminum diamond panels have a wide range of uses due to their unique properties. Some common applications include:

Flooring: Widely used in industrial settings, commercial buildings, and for the flooring of vehicles such as trucks, trailers, and RVs. The raised diamond pattern provides traction and reduces the risk of slips, making it ideal for areas where safety is a concern.

Stairs and Ramps: Aluminum diamond sheets are commonly used on stair treads and ramp surfaces to provide slip resistance and durability.

Decorative Applications: Due to its eye-catching appearance, aluminum diamond sheets are often used in architectural and interior design projects. It can be used on wall panels, wainscoting, countertops and backsplashes to add a modern and industrial aesthetic to a space.

Tool Chests and Storage: Due to its strength and durability, it is often used to build tool chests, storage bins, and cabinets.

Truck Bed Lining: Aluminum diamond sheets are commonly used as liners in truck beds and cargo areas to protect against damage caused by heavy loads and abrasives.

Trailers and Utility Vehicles: Because it is lightweight and corrosion-resistant, it can be used on the exteriors and floors of trailers, utility vehicles, and recreational vehicles (RVs).

Architectural decoration field: Diamond pattern aluminum plates are widely used for interior and exterior wall decoration, adding unique beauty and modernity to buildings. This kind of aluminum plate not only has a decorative effect, but also has functions such as shock absorption and fire prevention, which can effectively improve the reliability of the building.

Due to its unique appearance and excellent performance, diamond-shaped aluminum plates have been widely used in many fields such as architectural decoration, automobile manufacturing, electronic appliances, furniture, and aluminum mesh production.

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;