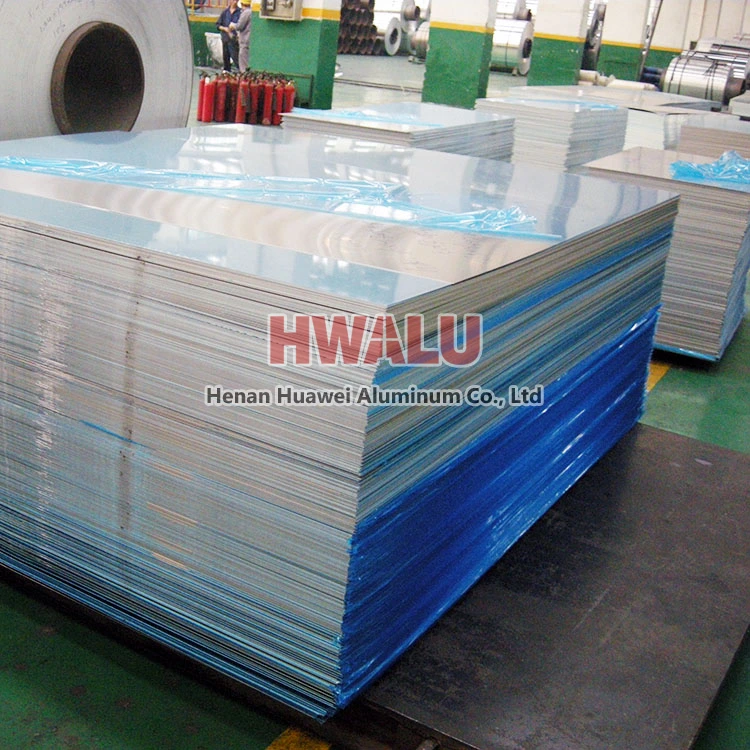

The most typical use of aluminum sheet for wall is aluminum curtain wall. The aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plates. Its common thickness is 1.5, 2.0, 2.5, 3.0MM, the model is 3003, and the state is H24. wall sheet Parameters of aluminum plain sheet plates for wall There are generally four thicknesses of curtain wall aluminum veneer: 1mm thickness, ...

what is Perforated aluminum plate? Perforated aluminum plate refers to pure aluminum or aluminum alloy material made by pressure processing (shear or saw cut) to obtain a rectangular cross-section, uniform thickness of rectangular material. The perforated board is widely used in real life, and can be used as a decorative board (curtain wall board, wall sound-absorbing board, and ceiling decoration), beautiful ...

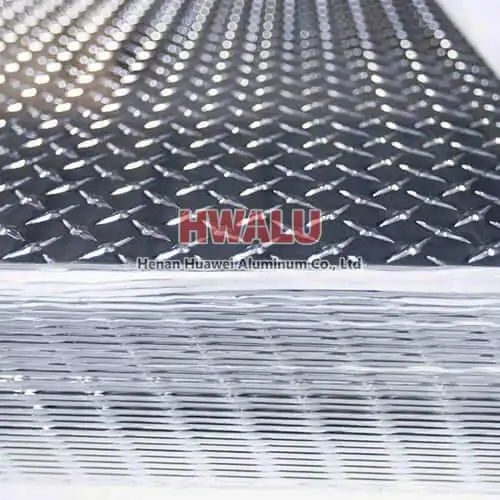

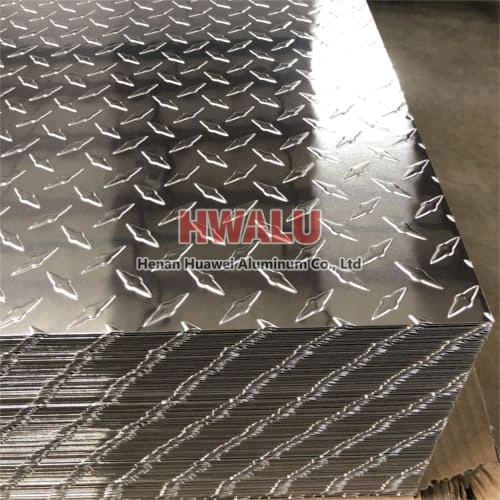

What is Aluminium Anti-slip Plate Aluminum anti-slip plate, also known as aluminum tread plate or aluminum checker plate, is a type of aluminum sheet with a raised pattern on one side to provide enhanced slip resistance. This pattern, often in the form of diamonds or bars, helps to reduce the risk of slipping and improves safety in various applications. Aluminum anti-slip plates are commonly used in industria ...

Medium thickness aluminum plate refers to aluminum plates with thick between 6mm ~ 25mm. For example, the commonly used aluminum plate thicknesses are 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 12.7mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm, 21mm, 22mm, 23mm, 24mm etc How to choose the medium and thick aluminum plate correctly The material of the medium and thick aluminum plates is relatively large, and many users ...

What is aluminum checker plate? Aluminum checker plate, also known as pattern aluminum plate or diamond aluminum plate, is an aluminum plate with a raised diamond pattern on one side. Aluminum checker sheet's unique pattern of raised diamonds or lines provides excellent anti-slip properties, making it ideal for applications where slip resistance is important. Aluminum checker plate thickness The applicatio ...

0.5mm aluminum sheet brief description 0.5mm aluminum sheet is a common metal material in industry and manufacturing. Its basic feature is that it is a rectangular plate with a thickness of 0.5mm, which is rolled and processed from aluminum or aluminum alloy. Aluminum sheets of this thickness are lightweight, highly corrosion-resistant, have good electrical and thermal conductivity, and are widely used. Advanta ...

The application of Aluminium in construction and architecture slowed in the 1940s, as the metal was predominantly used for producing planes. It even earned a second name, "winged metal." But as early as the middle of the twentieth century, Aluminium sheet became more and more popular in the construction of high-rise buildings and bridges. Window frames, panels, domed roofs and other wide-span constructions and or ...

Aluminium alloy 5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres. It has higher strength than 5251. This high strength makes 5754 highly suited to flooring applications. 5754 h111 aluminum sheet Applications: 5754 is typically used in: ~ Treadplate ~ Shipbuilding ~ Vehicle bodies ~ Rivets ~ Fishing industry equipment ~ Food processing ...

5052 aluminum plate and 6061 aluminum plate are the aluminum plates we often use. Although they are alloy aluminum plates, they still have obvious differences. The first is the difference in alloying elements. The alloying element of 5052 is magnesium, and the element of 6061 alloy contains silicon in addition to magnesium. Moreover, the processing conditions are different. Both the 6061 aluminum plate and the 5 ...

3004 aluminium alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose allo ...

3004 aluminum alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy ...

At present, we can see the use of brushed aluminum sheets everywhere, brushed aluminum sheet has been widely used in our life. The brushed aluminium sheet has different colors and different types, these colors look good and the surface treatment is very practical. In the aluminum grades, 1100, 3003, 6061 and 5052 are common used, and brushed aluminum sheet alloy 5052 has good performance on corrosion resistance. ...