Thin aluminum sheet refers to aluminium sheets with thick between 0.15mm ~ 2mm. The parameters of 5052 thin aluminum plate as an example are for reference only. If you want to know more about the thin aluminum plate, please contact us as soon as possible. Alloy State Thickness Width Tensile strength (Mpa) Elongation (δ%)(Scaling distance 50) 5052 0 >0.5~1.3 >1.3~4.5 Above 500mm ...

063 Aluminum Sheet introduction The ‘063 Aluminum Sheet’ refers to an aluminum sheet with a thickness of 0.063 inches, which is approximately 1.60mm. This type of sheet is known for its versatility and is commonly used in various applications due to its favorable properties such as corrosion resistance, good machinability, high strength after heat treatment, light weight, good weldability, and the ability to be ...

Introduction to 3004 aluminum sheet/plate? 3004 aluminum sheet is a non-heat-treatable aluminum alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 series also belongs to a series of aluminum manganese alloy. It has higher strength than 3003, exce ...

what is 3003 aluminum sheet? 3003 alloy metal aluminum sheet plate is approximately 20% stronger than 1100 series aluminium. 3003 alloy is readily formed by either conventional cold working or hot working. We offer high-quality 3003 flat aluminum sheet plate and tread plate covered by the ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547. The 3003-H14 is a softer, more formabl ...

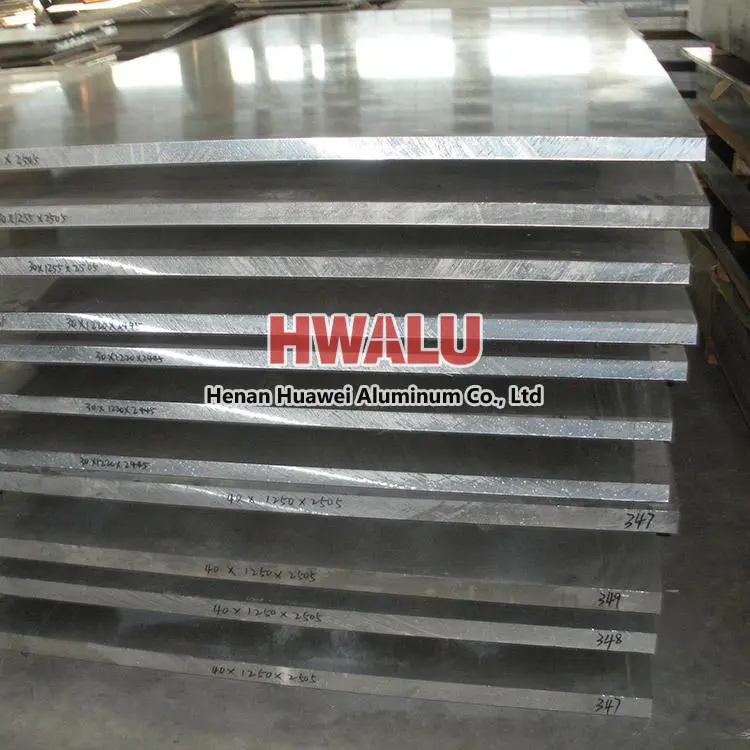

What is hot rolling? Hot rolling generally refers to rolling above the recrystallization temperature of the metal. During the hot rolling process, the metal deformation has both hardening and softening processes. Due to the influence of the deformation speed, as long as the recovery recrystallization process is too late, the metal will have a certain degree of work hardening with the increase of the deformation ...

Parameters of aluminum sheet plate for license plate Alloys: 1050, 1060, 6061 etc Temper: HO, H14, T6 etc Sizes: 6" 12" ( 12'' x 6'', 6x12 inch ), 10x5 ( 5"x10" ) etc Surface treatment: Anodized, color coated etc Application Aluminum plain license plates can be used in many places for stamped street traffic signs, laser cutting house door number sign, CNC embossing number metal aluminum logo automot ...

Aluminum plate has a wide range of applications. Building Aluminum composite panel ( ACP ) for architecture wall, corrugated aluminum roofing sheet, aluminum window, aluminum door, interior decoration etc Aerospace Aircraft body, aircraft floor etc Ship Boat body etc Car Automobile radiator. aluminum trailer siding sheets, engine turned aluminum sheet etc Food Aluminum sheet pan for baking Household appliances R ...

2024 aluminum sheet is the typical hard aluminum alloy, its composition is reasonable, comprehensive performance is better, is the largest amount of hard aluminum. 2024 Aluminum is a high strength precipitation/age hardening alloy with excellent fatigue resistance and durability. Used typically in structural, aircraft, and truck component manufacture, as well as hardware applications, aluminum 2024 is one o ...

3003 aluminum sheet is a very cost effective grade, as it combines substantial strength and corrosion resistance, with an attractive finish. It is used for stamped and formed parts and can be finished with mechanical and organic finishes. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels 3003 Aluminum Alloy contains Manganes ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. 3003 Aluminum Alloy contains Manganese as its major alloying element. 3003 Aluminum is an alloy with very good corrosion resistance and moderate strength. It is not heat treatable and develops strengthening from cold working only. 3003 ...

3004 aluminum plate :3004 series aluminum plate also belongs to a series of aluminum manganese alloy, the strength is higher than 3003, excellent formability, good corrosion resistance, the component strength is higher than 3003 alloy. 3004 is an aluminum-manganese alloy, which is the most widely used antirust aluminum. The alloy has a low strength (slightly higher than industrial pure aluminum) and cannot be ...

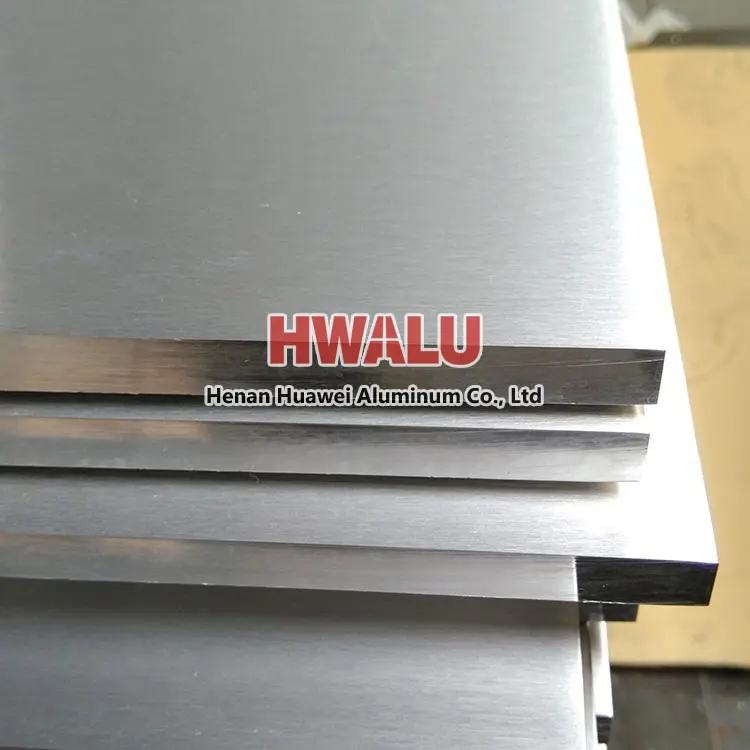

Hot rolling mill aluminum sheet generally refers to the rolling of metal above the crystallization temperature. Compared with ordinary cast-rolled products, hot-rolled aluminum sheet has good surface quality, while the mechanical properties as well as ductility are stronger and oxidation effect is good. Cold rolling aluminum sheet is also called cast aluminum sheet, cold rolling usually refers to the rolling o ...