What is 040 Aluminium Sheet The 040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material that is commonly used in various applications, including automotive, aerospace, construction, and industrial applications, as well as for general fabrication and DIY projects. Approximate search keywords of 040 Alu ...

what is 6082 aluminum sheet? 6082 aluminum sheet heat treatment can strengthen the alloy, with good formability, weldability, machinability and corrosion resistance, while a moderate strength, after annealing can still maintain good operability, mainly for mechanical structure Including bar, sheet, pipe and profile. 6082 and 6061 aluminum plate are both Al-Mg-Si aluminum alloy which can be strengthened by agi ...

7 Series aluminum alloys overview 7 series aluminum alloys are aluminum-magnesium-zinc-copper alloys, mainly zinc, but sometimes magnesium and copper are also added in small amounts. Among them, super hard aluminum alloy is the alloy containing zinc, lead, magnesium and copper, which is close to the hardness of steel. 7xxx series aluminum alloys are heat treatable alloys, which are super hard aluminum alloys ...

Definition of 4mm aluminum sheets A 4mm aluminum sheet, also known as an aluminum plate, is a panel of aluminum that is 4 millimeters thick. It’s a result of basic raw-form aluminum being pressed and rolled into panel form under high pressure. Aluminum sheets are characteristically manufactured to be very thin and lightweight, yet sturdy enough to offer extreme versatility alongside inherent ease of installat ...

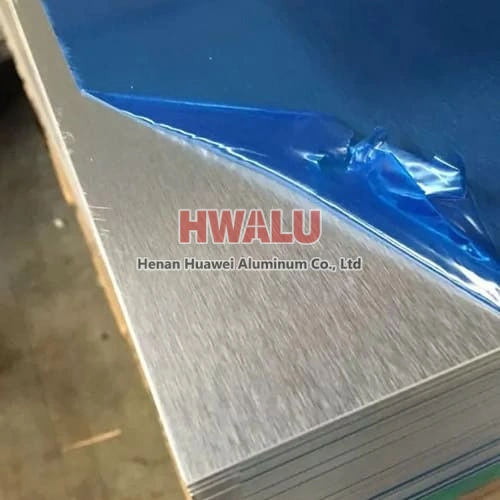

What is brushed aluminum sheets Brushed aluminum sheets are aluminum sheets that have a brushed finish applied to them. This finish is achieved by mechanically brushing the surface of the aluminum with a fine abrasive material. The brushing process creates a distinctive pattern of fine lines on the surface, giving the aluminum a stylish, modern look. Brushed aluminum sheets are commonly used in interior a ...

1. 6063 Mg-Si alloy is formulated as the main alloying element, the content of each element has a certain range, the high price of magnesium. 2. 6061-T6 aerospace called duralumin, light weight, high strength, high production costs, so expensive. Is abbreviated 6061 T6 aluminum aviation, have good formability, weld ability and machinability, also has moderate intensity, after annealing can be maintained better ...

1. Changes in daily aluminum plate prices As the basic raw material of aluminum plate, the price fluctuation of aluminum ingot directly affects the price of aluminum plate. 2. Surface spraying process of aluminum plate Common surface treatment processes for aluminum plate manufacturers include: fluorocarbon paint spraying, polyester paint spraying, thermal transfer wood grain, imitation stone grain spray ...

5052-H32 Aluminum Sheet Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels th ...

What are the advantages of 1060 aluminum sheet used in bus duct? With the emergence of modern engineering facilities and equipment, the power consumption of all walks of life has increased rapidly. In order to meet the requirements of high-current power transmission systems, plug-in bus ducts have emerged as new distribution wires. Among them, the aluminum sheet for bus duct is generally 1060 aluminum sheet, so ...

5052 anti-rust aluminum plate is an AL-Mg alloy aluminum plate, which is the most widely used anti-rust aluminum. This alloy has high strength, especially fatigue resistance: high plasticity, and corrosion resistance, and cannot be strengthened by heat treatment. Good plasticity when semi-cold work hardening, low plasticity when cold work hardening, good corrosion resistance, good weldability, poor machinability, ...

6061 aluminum plate application for the mold making material.With aluminum sheet plate cost mold manufacturing indeed slightly higher, but the aluminum mold price is higher, because of its service life is far higher than other materials, and scrap aluminum can be recycled scrap value; compared to the previous aluminium die casting mould, it have a long life cycle, and does not appear to fall off. For example w ...