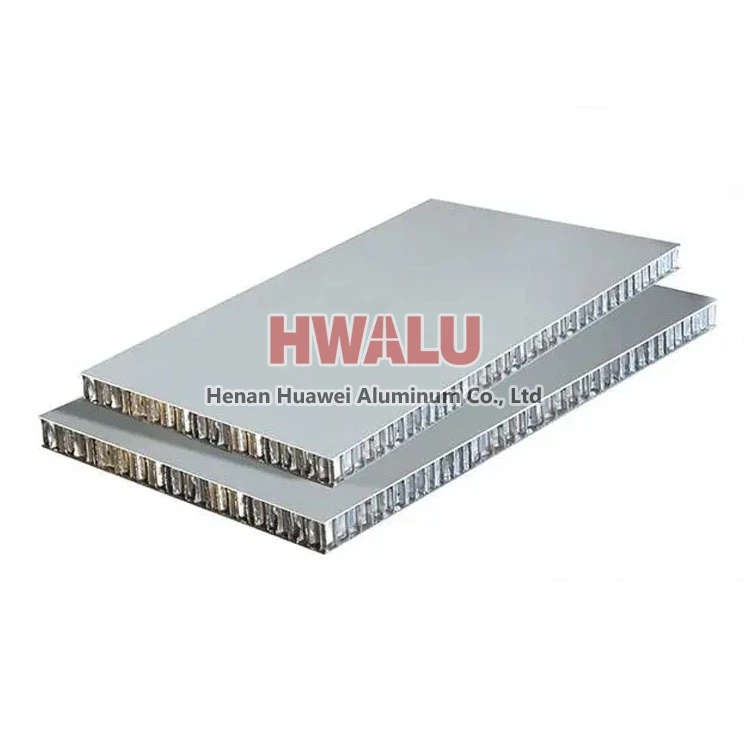

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

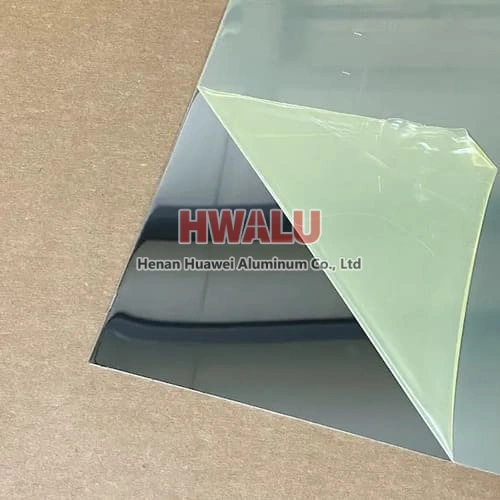

What is reflective aluminum sheet? What is aluminum sheet reflector? Reflective aluminum sheet, also known as mirror aluminum sheet or reflective aluminum, is a type of aluminum sheet. It has reflective surfaces that reflect light and heat. It has high reflectivity, also known as high reflective aluminum sheet. Reflective aluminum sheet refers to a thin and flat aluminum material that has been specially treated ...

Introduction Welcome to Huawei Aluminum, your leading provider of high-quality reflective aluminum lighting sheets. With years of expertise and dedication to innovation, we deliver superior products tailored to meet the diverse needs of our clients across various industries. Our reflective aluminum lighting sheets are designed to offer unmatched durability, reflectivity, and efficiency, catering to your specific ...

what is 3105 aluminum sheet? 3105 aluminum plate belongs to a series of Al-Mn alloy, good rust resistance, good electrical conductivity, including 98% aluminum content, because the addition of 0.3% copper content, electrical conductivity is 41%; 3105 aluminum plate can not be heat treatment and reinforcement, so the use of cold treatment to improve its mechanical properties: annealing state plasticity is high, s ...

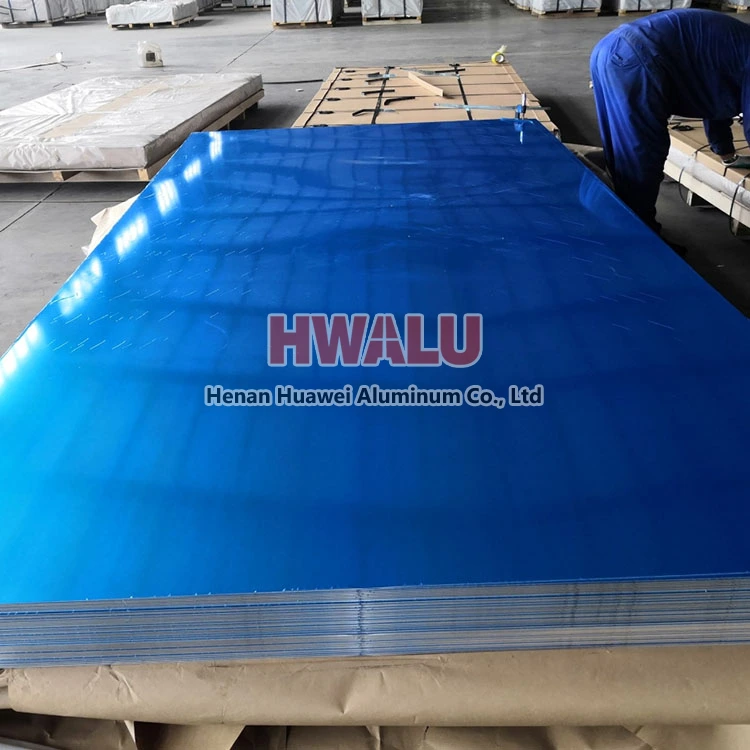

Welcome to Huawei Aluminum, your trusted manufacturer and wholesaler of high-quality Aluminium Floor Plates. Our products are designed to meet a wide range of industrial and architectural needs, offering durability, strength, and aesthetic appeal. Introduction Aluminium Floor Plates are widely used in various applications such as construction, automotive, aerospace, and marine industries. They are known for the ...

5052 aluminum plate and 6061 aluminum plate are the aluminum plates we often use. Although they are alloy aluminum plates, they still have obvious differences. The first is the difference in alloying elements. The alloying element of 5052 is magnesium, and the element of 6061 alloy contains silicon in addition to magnesium. Moreover, the processing conditions are different. Both the 6061 aluminum plate and the 5 ...

6063-T5 aluminum is 6063 aluminum in the T5 temper. To achieve this temper, the metal is artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 6063-T5 aluminum to: 6000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full ba ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

Aluminum 3105 alloy sheet has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2 t range for annealed H12, H14 and H16 tempers. Bend radii of 2 to 7 t should be used for the H18 temper. 6061 T6 Aluminum Sheet is an aluminum sheet product that is very versatile and has a wide range of applications. 6061 Aluminum sheet is made from one of the most widely used heat ...

5754 h14 h24 aluminium sheet utilized in the automobile indus After rolling, Aluminium sheet 5754 spontaneously softens until it reaches a stable condition.Medium mechanical properties,weldability and ease of processing forming characteristics such as Al-Mg alloy typical alloys.Aluminium 5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres.It has higher strength ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...