aluminum 6061-t651 material properties 0.75" 6061-T651 is the main alloy of 6061 alloys. It is a high-quality aluminum alloy product produced by heat treatment and pre-drawing process. Although its strength cannot be compared with the 2XXX series or 7XXX series, it has many magnesium and silicon alloy characteristics, such as excellent machining performance, excellent welding characteristics, electroplating, goo ...

How thick is 030 aluminum sheet? 030 aluminum sheet is a way of expressing the thickness of aluminum sheet, representing 0.03 inches. The aluminum sheet with a thickness of 0.030 is 0.762mm, which is a commonly used thickness specification. 030 aluminum sheet equivalent keywords 030 aluminum plate 030" aluminum sheet 0.030" aluminum sheet 030 inch aluminum sheet 0.03" aluminum sheet 0.030" a ...

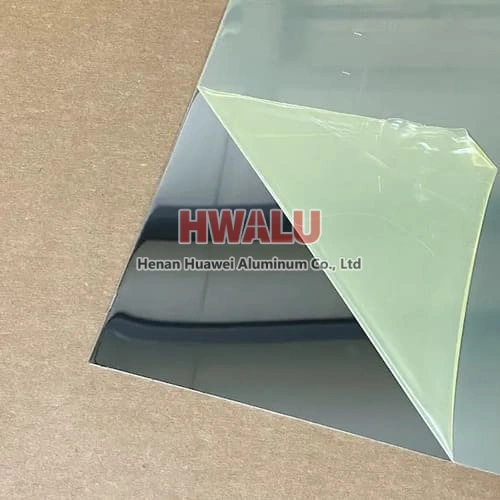

What is reflective aluminum sheet? What is aluminum sheet reflector? Reflective aluminum sheet, also known as mirror aluminum sheet or reflective aluminum, is a type of aluminum sheet. It has reflective surfaces that reflect light and heat. It has high reflectivity, also known as high reflective aluminum sheet. Reflective aluminum sheet refers to a thin and flat aluminum material that has been specially treated ...

what is 6063 aluminum sheet? 6063 aluminum sheet is Al-Mg-Si alloy, with excellent processing performance, excellent solderability, extrusion and plating, good corrosion resistance, toughness, easy polishing, anodizing Excellent effect, is a typical extruded alloy. 6063 Aluminum sheet is widely used in construction profiles, irrigation pipes, vehicles, benches, furniture, lifts for its good plasticity. Mi ...

Introduction of 5086 aluminum sheet 5086 alloy metal aluminum sheet plate - an aluminum alloy with the primary alloy element being magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material. Since heat treatment doesn't strongly affect the strength, 5086 can be readily welded and retain most of its mechanical strength. The go ...

What does the 4x8 in the 4x8 foot aluminum plate mean? In general, 1'=1 foot (symbol ft) = 12 inches (12") = 30.48 cm = 304.8 mm 1"=1 inch ( inch is abbreviated as in or " ) = 2.54 cm = 25.4 mm (actual value is 2.539999918 cm.) So, 4 in 4 x 8 foot is 4 x 304.8 mm = 1219.2 mm = 1.2192 m ≈ 1220mm ≈ 1.22 m 8 in 4 x 8 feet is 8 x 304.8 mm = 2438.4 mm = 2.4384 meters ≈ 2440mm ≈ 2.44 m i.e. 4x8 foot = 1.22m ...

7075-T6 aluminum is 7075 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 7075-T6 aluminum to: 7000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the re ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

There are many anodic oxidations for aluminum alloys, which can be used in daily life. Because of the characteristics of this process, a hard protective layer is produced on the surface of aluminum parts, which can be used to produce kitchen utensils and other daily necessities. However, the anodizing effect of cast aluminum is not good, the surface is not good, and it can only be black. The aluminum alloy profil ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

Aluminum is an extremely popular choice for sheet metal suppliers due to its cost effectiveness, flexible nature, and range of options and grades. For example, high strength aluminum can be specialized for the aerospace industry, while corrosion resistant aluminum alloys are ideal for marine applications. It is highly weldable, machinable, and weather resistant. Common grades of aluminum include: Grade 1100-H14 — ...

1060 sheet aluminium is pretty similar to 1050 aluminum alloy with more than 0.1% of aluminum by weight. Both 1050 and 1060 sheet aluminium of huawei aluminum . lives up to ISO standards, but they cover different ASTM standards. 1060 sheet aluminium contains 0.05% cooper, thus, its conductivity is 55%. Besides, 1060 aluminum plate is relatively low strength, essentially pure aluminum alloy plate with many differe ...