Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

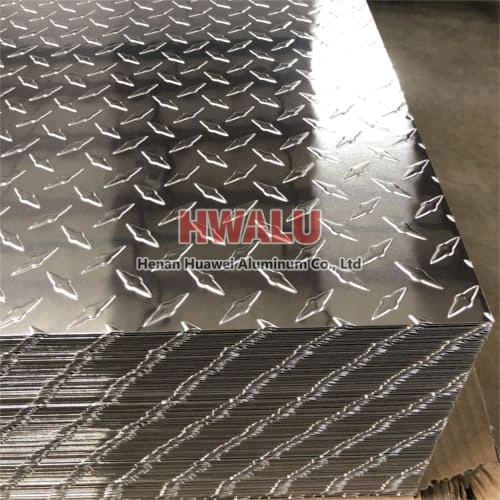

What is aluminum checker plate? Aluminum checker plate, also known as pattern aluminum plate or diamond aluminum plate, is an aluminum plate with a raised diamond pattern on one side. Aluminum checker sheet's unique pattern of raised diamonds or lines provides excellent anti-slip properties, making it ideal for applications where slip resistance is important. Aluminum checker plate thickness The applicatio ...

How thick is 030 aluminum sheet? 030 aluminum sheet is a way of expressing the thickness of aluminum sheet, representing 0.03 inches. The aluminum sheet with a thickness of 0.030 is 0.762mm, which is a commonly used thickness specification. 030 aluminum sheet equivalent keywords 030 aluminum plate 030" aluminum sheet 0.030" aluminum sheet 030 inch aluminum sheet 0.03" aluminum sheet 0.030" a ...

what is Perforated aluminum plate? Perforated aluminum plate refers to pure aluminum or aluminum alloy material made by pressure processing (shear or saw cut) to obtain a rectangular cross-section, uniform thickness of rectangular material. The perforated board is widely used in real life, and can be used as a decorative board (curtain wall board, wall sound-absorbing board, and ceiling decoration), beautiful ...

what is 7075 aluminum sheet? 7075 alloy metal aluminum sheet plate is a common alloy in 7000 series aluminum alloy sheet. 7075 aluminum sheet (Al-Zn-Mg-Cu) belongs to super-hard aluminum. As a kind of cold finished wrought alloy, it has great strength and hardness. It’s far better than mild steel. This alloy has good mechanical properties and anode reaction. 7075 aluminum sheet as a typical kind of aerospace al ...

The most typical use of aluminum sheet for wall is aluminum curtain wall. The aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plates. Its common thickness is 1.5, 2.0, 2.5, 3.0MM, the model is 3003, and the state is H24. wall sheet Parameters of aluminum plain sheet plates for wall There are generally four thicknesses of curtain wall aluminum veneer: 1mm thickness, ...

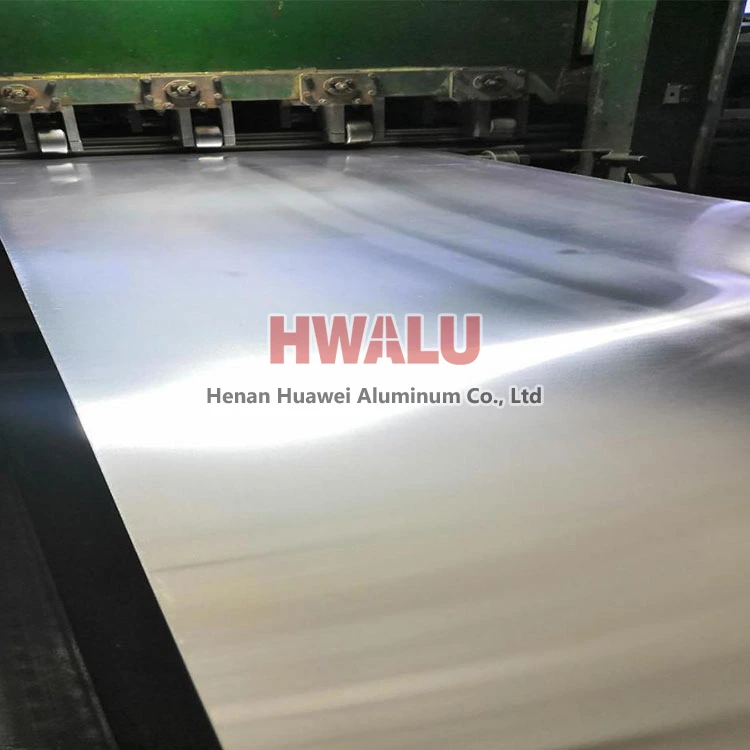

Analyze the hot rolled aluminum sheet process The hot rolled aluminum sheet includes the preparation process of rolling raw materials and the rolling process. The preparation process of the raw material for rolling includes sawing of the ingot head and tail, side milling or planing, face milling, etching, welding or bundling of aluminum-clad or composite plates, and heating. The rolling process includes rough ro ...

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manu ...

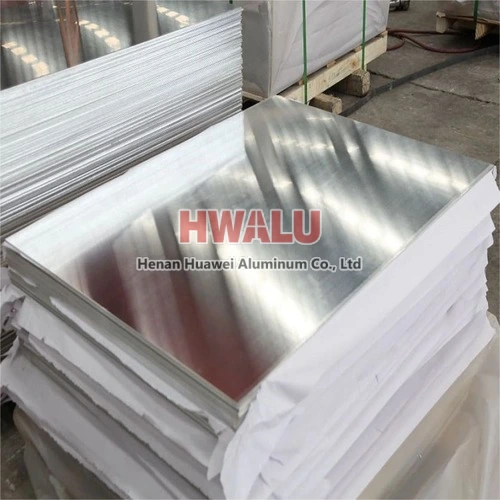

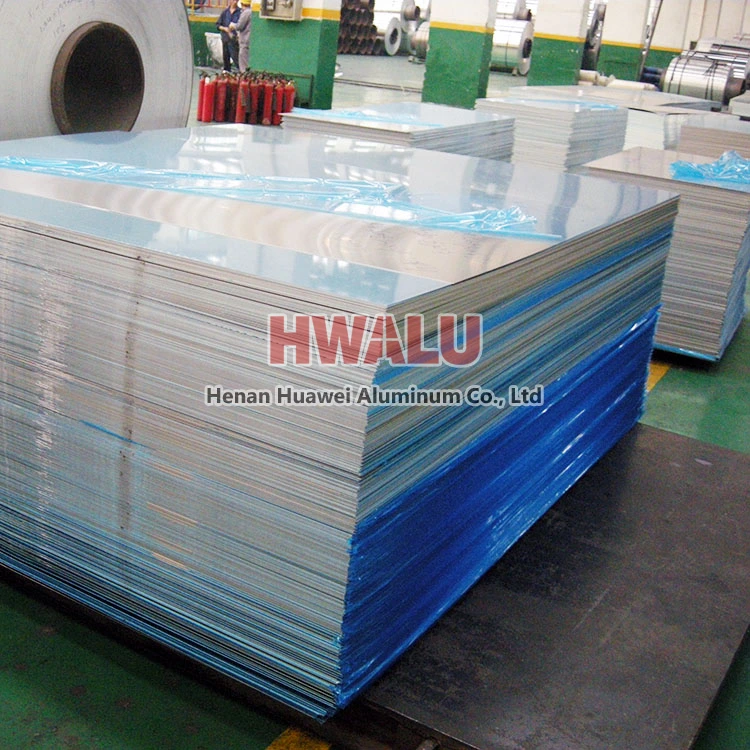

Aluminum is an extremely popular choice for sheet metal suppliers due to its cost effectiveness, flexible nature, and range of options and grades. For example, high strength aluminum can be specialized for the aerospace industry, while corrosion resistant aluminum alloys are ideal for marine applications. It is highly weldable, machinable, and weather resistant. Common grades of aluminum include: Grade 1100-H14 — ...

7005-T6 aluminum is 7005 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 7005-T6 aluminum to: 7000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the re ...

The definition of aluminum plate density Density refers to the ratio of mass to volume of an object, usually expressed in grams per cubic centimeter. The density of the aluminum plate refers to the mass of the aluminum plate per unit volume, that is, the ratio of the mass to the volume of the aluminum plate. The density of the aluminum plate is closely related to the composition of the aluminum alloy, the manufa ...

3105 Painted Aluminum SheetPre-painted Finishes offer extreme durability in outdoor exposure as well as indoors because of our high-quality paint system. Pre-painted aluminum sheet finishes are uniquely designed in that they offer a hard, abrasive resistant coating, yet allow the flexibility for extensive forming and fabricating. Aluminum sheet 6061 T4 is used in many types of industrial applications, includin ...