Parameters of aluminum sheets for cookware Alloy 3004 etc Sizes 4'x8',4'x10',5'x10,'400x400mm, 40*30cm, 400x300cm, 13" x 18", 18 x 28 inch, 16-inch by 22-inch, 9x 13.5 inches Thickness 1/8", 16 gauge, 1/4" Feature food grade Applications of aluminium flat sheets for cookware Custom square aluminum pans for baking ( cookie, beans pudding ), barbecue cooking sheet, open bead cake p ...

Extra width aluminum sheet, generally refers to the width of more than 1.8 meters of aluminum sheet. Parameters of wide aluminum sheet plate Width: 1800mm, 1900mm, 2000mm, 2100mm, 2200mm, 2300mm, 2400mm, 2500mm, 2600mm, even 2700mm, 2800mm, 2900mm, 3000mm ( super wide ) etc Ultra width aluminum sheets Max width: 3 m What's the application of extra wide aluminum plates? Roofing sheet material, containe ...

What are the characteristics of 4017 aluminum plate? 4017 aluminum sheet plate has a variety of thicknesses and pattern sizes. 4017 aluminum alloy is a shiny surface similar to 3003. 4017 aluminum alloy provides durability. The constructed aging isotherm shows that EN 4017 with 0.19% Mg reaches a lower peak intensity than EN 4017 material with 0.43% Mg. The higher Mg variant of EN 4017 is comparable to the ag ...

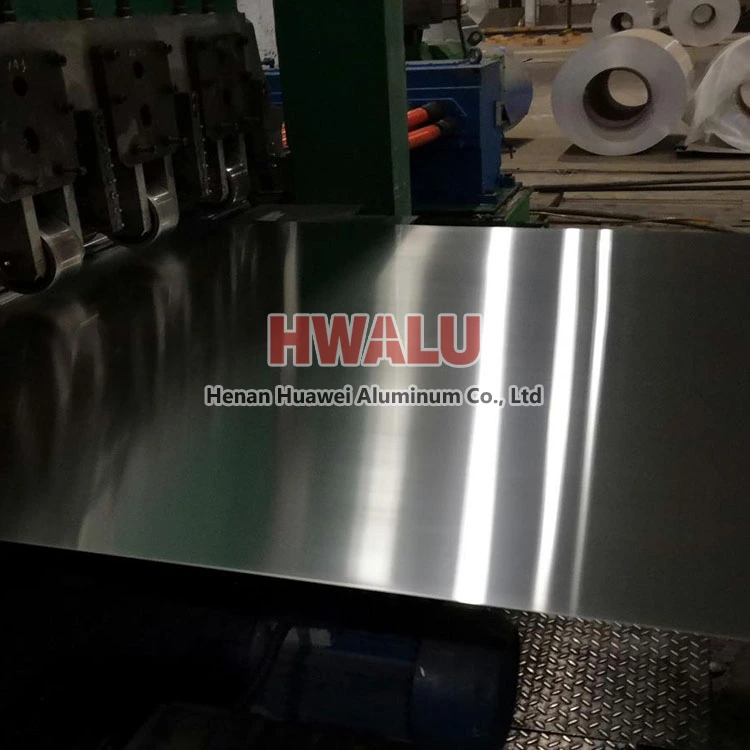

Aluminum sheets Main products include 1-8 series aluminum plate/strip/coil/foil. We also produce mirror aluminum sheet, aluminum checkered plate, tread plate, embossed aluminum plate,etc a.Light weight b.Low cost c.Easier and convenient to install d.Environmental friendly and energy saving e.Anti-dirt and self-cleaning f.Corrosion resistant and moisture proof g.Weathering resistance strong ...

What is 4x8 diamond plate aluminum sheets A 4x8 diamond plate aluminum sheet is a standard-sized sheet of aluminum that has been embossed with a diamond pattern. The dimensions of the sheet are 4 feet by 8 feet. Advantages of using 4x8 diamond plate aluminum sheets 4x8 diamond plate aluminum sheets have several advantages that make them a popular choice for various applications: 1. Skid-resistance: Th ...

5052 aluminum sheet is often referred to as ""Anodize Quality Aluminum"", as it has excellent finishing qualities and anodized coatings are bright and clear. The major alloying element in 5052 is magnesium in sufficient quantities to cause substantial lowering of the melting point without producing brittleness. When magnesium is used as the major alloying element, or in combination with manganese, the result is a ...

Aluminum 5754 has amazing consumption protection particularly to seawater and mechanically polluted atmospheres. Aluminum 5754 has excellent corrosion resistance particularly to seawater and modernly dirtied environments. It has higher quality than 5251. This high quality makes 5754 exceedingly suited to deck applications.These 5754 aluminum plate are available in different shape size and thickness according to t ...

1060 aluminum sheet is another representative product in 1000 series aluminum alloys. 1060 aluminum alloy is formed by pure aluminum added by a small amount of copper element, which has excellent forming processing characteristics, high corrosion resistance, good weld ability and conductivity. The same as 1050 aluminum sheet, the aluminum sheet 1060 is widely used in products with low strength requirements, such ...

1100 aluminum sheet for industrial pure aluminum, aluminum content (mass fraction) of 99%, non heat treatment. It has high corrosion resistance, electrical conductivity and thermal conductivity, low density, good plasticity, and can be used to produce all kinds of aluminum, but the strength is low. Other processes are basically the same as 1050A. 1100 aluminum sheet commonly used to have good machining performanc ...

A variety of small defects often appear on the surface of aluminum plates, such as unevenness, fracture, uneven thickness, etc. What are the reasons for these defects? Now the aluminum plate manufacturer will answer you one by one from the following seven aspects Bar: 1. The roll shape of the aluminum plate is incorrectly folded (folded), such as heating of the calender bearing; 2. Air bubbles on the surface of ...

2024 aluminum sheet is the typical hard aluminum alloy, its composition is reasonable, comprehensive performance is better, is the largest amount of hard aluminum. 2024 Aluminum is a high strength precipitation/age hardening alloy with excellent fatigue resistance and durability. Used typically in structural, aircraft, and truck component manufacture, as well as hardware applications, aluminum 2024 is one o ...