6061-t6 material properties 6061-T6 is aluminum, magnesium, silicon alloy, gold, heat treatment corrosion resistant alloy. The strength and corrosion resistance are different, and the uniformity is good. 6061 T6 high strength, high hardness (up to HV 90 degrees or more), good processing effect, good oxidation effect. No sand hole, good flatness. Improve processing efficiency and reduce material cost. Widely u ...

Welcome to Huawei Aluminum, your trusted manufacturer and wholesaler of high-quality 16 gauge aluminum sheets. Our products are designed to meet a wide range of industrial and architectural needs, offering durability, strength, and versatility. Introduction 16 gauge aluminum sheets are widely used in various applications such as construction, automotive, aerospace, and marine industries. They are known for thei ...

There are fewer manufacturers producing 2000 series aluminum sheets in China. The quality is not yet comparable to that of foreign countries. At present, the imported aluminum plates are mainly provided by Korean and German producers. With the development of China's aerospace industry, 2000 series aluminum plate production technology will be further improved. 2000 series aluminum plate is characterized ...

what is 6000 series aluminum sheet? 6 series aluminum alloy mainly contains two elements of magnesium and silicon, also known as "aluminum-magnesium-silicon alloy", is a heat treatment type of corrosion-resistant aluminum alloy, with high strength and corrosion resistance, good uniformity, excellent processing performance, excellent welding characteristics and plating, good corrosion resistance, high toughness a ...

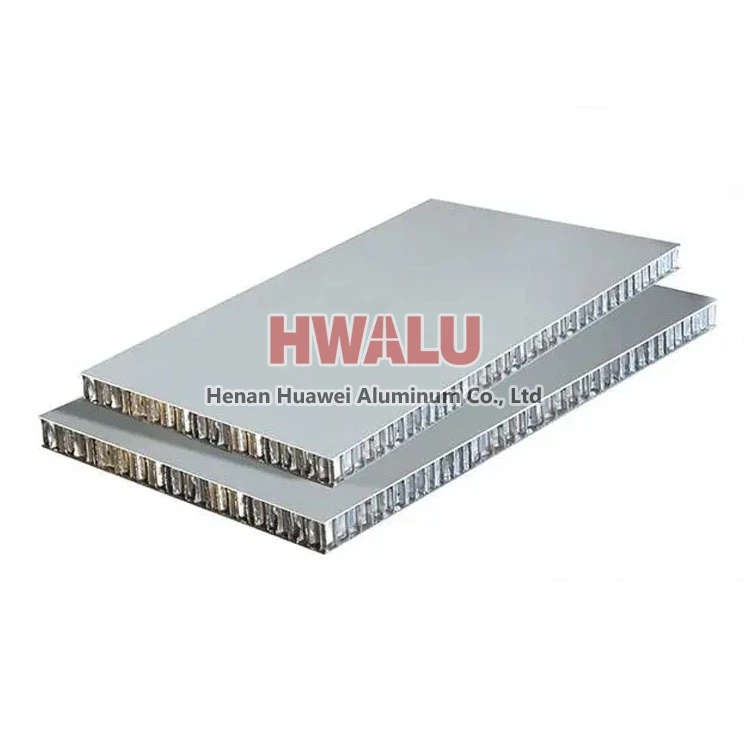

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

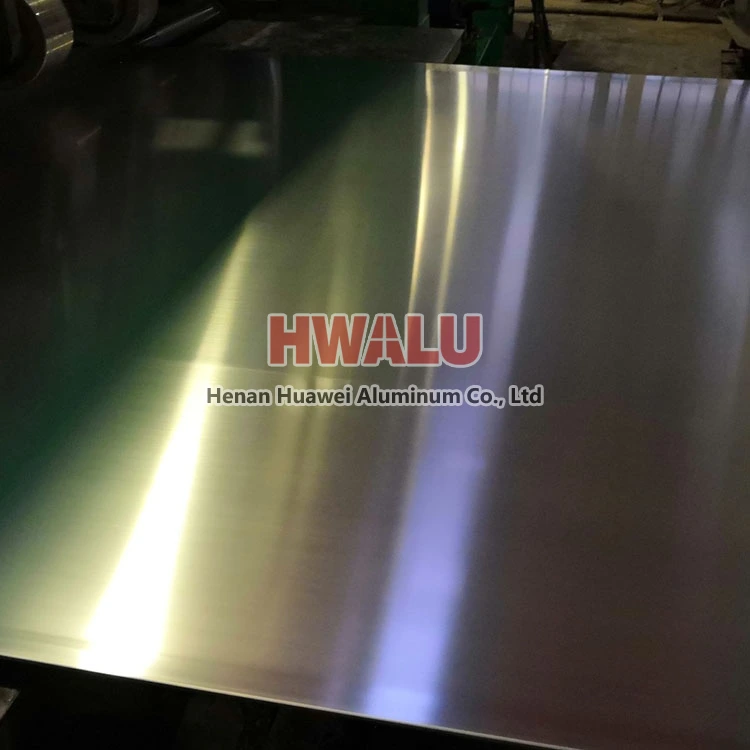

That is Mirror aluminum sheet polishing process!Mirror aluminum refrigerator copper aluminum tube welding video 5083 aluminum pipe fittings veneer with mirror effect is popular, is widely used in lighting lamps and lanterns reflective panels and decorative lamps and lanterns, solar reflective materials, interior decoration, integration ceiling, wall decoration, household electrical appliance panels, electronic pr ...

1. Cut corners With the continuous improvement of the national quality control system, the phenomenon of cutting corners is not as rampant as before. However, in order to reduce production costs, there are still some companies who take risks by cutting corners and using molds of substandard quality in the process of producing aluminum veneer products. , Resulting in unqualified wall thickness of the aluminum p ...

6061 T6 Aluminum Sheet is an aluminum sheet product that is very versatile and has a wide range of applications. 6061 Aluminum sheet is made from one of the most widely used heat treatable aluminum alloys. This sheet has excellent corrosion resistance, good workability and good machinability. 6061 sheet applications include a wide variety of products from medical assemblies, aircraft construction to structural co ...

7075-T6 Aluminum Sheet is primarily used in aerospace industry, often referred to as the Strongest Aluminum grade. Alloy 7075 has the strength of many steels, while retaining aluminum’s lightweight qualities. 7075 aluminum sheet is one of the highest strength aluminum alloys available Its strength-to weight ratio is excellent and it is ideally used for highly stressed parts. It may be formed in the annealed co ...

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manu ...