what is 6063 aluminum sheet? 6063 aluminum sheet is Al-Mg-Si alloy, with excellent processing performance, excellent solderability, extrusion and plating, good corrosion resistance, toughness, easy polishing, anodizing Excellent effect, is a typical extruded alloy. 6063 Aluminum sheet is widely used in construction profiles, irrigation pipes, vehicles, benches, furniture, lifts for its good plasticity. Mi ...

What is the thickness of 3/16 thick aluminum plate? The thickness of the aluminum 3/16 plate is expressed in millimeters: 1 inch = 25.4mm 25.4*3/16 = 4.7625 3/16 inch = 4.7625 mm The thickness of 3/16 sheet aluminum is expressed in feet: 1 foot = 12 inches 3/16 inch = 0.015625 feet 3 16 thick aluminum sheet How to calculate the weight of 3 16 aluminum sheets per unit area? 3 16 alumi ...

what is 3003 aluminum sheet? 3003 alloy metal aluminum sheet plate is approximately 20% stronger than 1100 series aluminium. 3003 alloy is readily formed by either conventional cold working or hot working. We offer high-quality 3003 flat aluminum sheet plate and tread plate covered by the ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547. The 3003-H14 is a softer, more formabl ...

what is Aluminum corrugated sheet? Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold- ...

What is 22 gauge aluminum sheet? 22 gauge aluminum sheet refers to an aluminum sheet with a specific thickness. 22 gauge represents the thickness of the aluminum sheet, which is approximately 0.0253 inches aluminum sheet or 0.643mm thickness aluminum sheet. Aluminum sheet 22 gauge has a thickness of less than 1mm and has good processability and formability. It is used for bending, stamping, cutting and forming ...

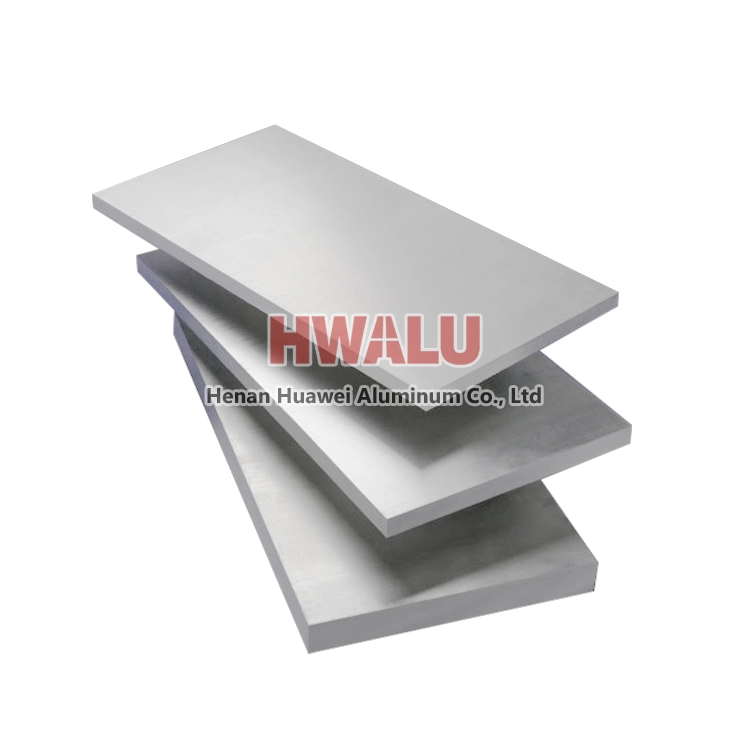

Medium thickess aluminum plate refers to aluminium plates with thick between 25mm ~ 200mm. Unit ( mm ): 25mm, 25.4mm, 26mm, 27mm, 28mm, 29mm, 30mm, 35mm, 40mm, 45mm, 50mm, 50.8mm, 100mm etc Unit ( cm ): 10 cm etc Unit ( inch ): 1, 2 etc

1060 1100 3003 3105 Annealed Polished Aluminum Sheet Plates For Industries Quick Detail: Product Alloy Temper Thickness(MM) Width(mm) Aluminium sheet 1100 1050 1060 3003 3005 5052 8011 O-H112 0.16~200 500-2200 Description: Specifications of Aluminum Alloy Sheet: 1. Grade 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3102 3104 3105 3A21 etc ...

Several main reasons and precautions for cracking of aluminum plate after bending: Hardness of aluminum plate The hardness of the aluminum plate is too high and it is easy to crack. This requires the selection of high-quality aluminum plates, mainly depending on the alloy and state of the aluminum plates. The hardness of the 6 series and 7 series is higher than that of the 1, 3, and 5 series. It needs to be ann ...

The aluminum veneer curtain wall is made of high-quality high-strength aluminum alloy plate, the common thickness is 1.5, 2.0, 2.5, 3.0MM, the model is 3003, and the state is H24. Its structure is mainly composed of panels, reinforcing ribs, and corner yards. The corners can be bent and stamped directly from the panel, or riveted to the small edge of the panel. The reinforcing rib is connected with the welding sc ...

Alloy 7075 has been thoroughly evaluated for corrosion resistance of atmospheric weathering, stress-corrosion cracking and exfoliation in all currently available tempers. These values have been used as a standard for comparison in the development of more recent high strength aerospace alloys and used for highly stressed structural parts in the aerospace and defense industries, and as mold material in the plastics ...

What does 4x8 aluminium plate mean? 4 means the width of the aluminum plate is 4 feet 4 feet = 1.219 meters ≈ 1220 mm 8 means the length of the aluminum plate is 8 feet 8 feet = 2.438 meters ≈ 2440 mm Therefore, what we usually call a 4x8 aluminium plate is an aluminum plate with a length of 2.4 meters and a width of 1.2 meters. 4x8 aluminium sheet How much does a 4x8 sheet of 3/16 aluminum weigh? ...

You must be familiar with 5052 aluminum sheet, but I would like to say that you are also familiar with 5052 aluminum sheet insulation aluminum coil? Recently, many customers have begun to try to use 5052 aluminum sheet insulation aluminum coil for pipe insulation. There are also more partners inquiring about this issue. We are also actively and constantly exploring. We can't help but ask if there are any advantag ...