Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

8000 Series Aluminum Sheet Overview Features: It belongs to aluminum-lithium alloy, and its main component is lithium, because lithium is the lightest metal in nature. When lithium is added to the aluminum sheet, it can effectively reduce the ratio of aluminum sheet, while ensuring the strength of the aluminum sheet. Purpose: Aluminum plates with bottle caps as the main function are also used in radiators, ...

What is diamond aluminum sheet? Diamond aluminum plate, also known as diamond plate or diamond pattern plate, is an aluminum plate with a raised diamond pattern on one side. The diamond-shaped aluminum plate pattern provides increased traction and durability, making it ideal for applications where slip resistance is important, such as industrial floors, stairs, ramps and truck beds. Aluminum diamond sheet c ...

what is 6000 series aluminum sheet? 6 series aluminum alloy mainly contains two elements of magnesium and silicon, also known as "aluminum-magnesium-silicon alloy", is a heat treatment type of corrosion-resistant aluminum alloy, with high strength and corrosion resistance, good uniformity, excellent processing performance, excellent welding characteristics and plating, good corrosion resistance, high toughness a ...

what is Aluminum corrugated sheet? Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold- ...

Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, decoration materials, thermal insu ...

Aluminum sheet alloy 1050 is a common grade of 1000 series aluminum sheet plate, it belongs to pure aluminum plate sheet series. The mechanical properties of the 1050 aluminum sheet are not high, but because of the simple production process and mature technology, it has great advantages in price and high cost performance. Aluminum sheet 1050 is suitable for applied in industries that do not have strict require ...

1100 aluminum sheet for industrial pure aluminum, aluminum content (mass fraction) of 99%, non heat treatment. It has high corrosion resistance, electrical conductivity and thermal conductivity, low density, good plasticity, and can be used to produce all kinds of aluminum, but the strength is low. Other processes are basically the same as 1050A. 1100 aluminum sheet commonly used to have good machining performanc ...

5754-H22 aluminum is 5754 aluminum in the H22 temper. To achieve this temper, the metal is strain hardened, and then partially annealed, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H28). The graph bars on the material properties cards below compare 5754-H22 aluminum to: 5000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar m ...

Commonly, high-speed rail sound barrier is commonly used 5754 aluminum sheet and 5a03 aluminum alloy, which are with high strength and corrosion-resistant. On the other hand, the 5754 aluminum alloy can also be applied in the auto car industry. The 5754 and 5a03 alloy aluminum sheet are the same as Al-Mg anti-rust alloy aluminum plate, with a thickness of 1.5mm and a width of 610-750mm. However, there may be a ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum sheet has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

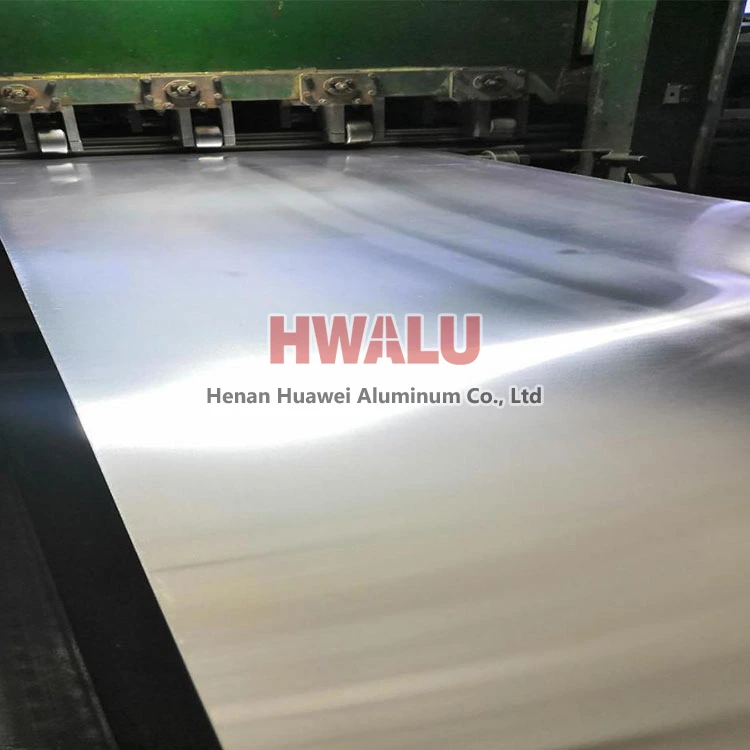

Henan Huawei Aluminium Co., Ltd, a professional aluminum sheet manufacturer, specializes in producing series 1, 3, 5, 6 and 7 aluminum alloy sheet, aluminum coil and aluminum foil, aluminum circle, hot rolled alloy plate etc. Therefore, whatever you want to order, we can provide products for you. Look forward to becoming your closest business partner and building business relationship with you in the future. Don ...