What is 5052 aluminum sheet/plate? 5052 alloy metal aluminum sheet plate belongs to 5000 series aluminum sheet, which is highly resistant to corrosion. It belongs It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium, and it belongs to 5 series. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments ...

0.75 aluminum sheet product introduction 0.75 aluminum sheet refers to an aluminum sheet with a thickness of 0.75 inches, which translates into an aluminum sheet with a thickness of 19mm. Aluminum sheet 0.75 sheet is typically made from a variety of aluminum alloys, including 3003, 5052, 5083, and 6061. 0.75 aluminum sheet equivalent keywords 0.75" aluminum sheet 0.75 inch aluminum sheet 0.75 in al ...

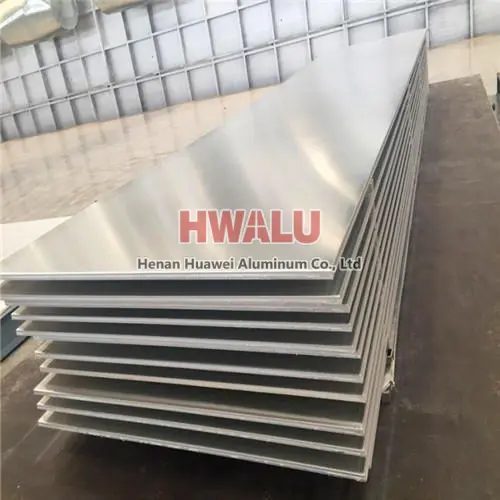

Aluminum sheet plate refers to aluminum material with width of 200mm over. Standard width: 1000mm, 1200mm, 1220mm etc 4x4 ft ( 4 x 4 ), 48x48 inch ( 48 x 48 ), 1219.2 x 1219.2 mm 4x6 ft ( 4 x 6 ), 48x72 inch ( 48 x 72 ), 1219.2 x 1828.8 mm 4x8 ft ( 4 x 8 ), 48x96 inch ( 48 x 96 ), 8x4 ft ( 8 x 4 ), 1219.2 x 2438.4 mm 4x10 ft ( 4 x 10 ), 48x120 inch ( 48 x 120 ), 1219.2 x 3048 mm 4x12 ft ( 4 x ...

what is 1/16" 5052-H32 Aluminum Plate? 1/16" 5052 H-32 Aluminum - Aluminum alloy containing magnesium is stronger than series 3003 aluminum. This grade has excellent corrosion resistance and the best welding characteristics of all aluminum. Applications include truck and trailer parts, aircraft parts, hulls, ladders, railings, toolboxes, kitchen equipment, trim pieces, sign billets, and any other application ...

Introduction Huawei Aluminum, a renowned name in the aluminum industry, specializes in the production and wholesale of 5x10 foot aluminum sheet plates. Our products are designed to cater to a diverse range of applications, from construction to manufacturing, while maintaining high standards of quality and durability. With a commitment to excellence, we offer an extensive selection of alloy models and specificati ...

There are fewer manufacturers producing 2000 series aluminum sheets in China. The quality is not yet comparable to that of foreign countries. At present, the imported aluminum plates are mainly provided by Korean and German producers. With the development of China's aerospace industry, 2000 series aluminum plate production technology will be further improved. 2000 series aluminum plate is characterized ...

Aluminum 5754 has amazing consumption protection particularly to seawater and mechanically polluted atmospheres. Aluminum 5754 has excellent corrosion resistance particularly to seawater and modernly dirtied environments. It has higher quality than 5251. This high quality makes 5754 exceedingly suited to deck applications.These 5754 aluminum plate are available in different shape size and thickness according to t ...

5005 h24 aluminum alloy is an aluminium alloy with good resistance to atmospheric corrosion.It is used in decorative and architectural applications. It is a member of the 5000 series of aluminum-magnesium wrought alloys. As such, it is not used in casting. It can attain moderate to high strength by cold working, and has relatively high welded strength compared to other aluminum alloy families. Tempers H116 and H3 ...

3105-H14 aluminum is 3105 aluminum in the H14 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly halfway between annealed (O) and full-hard (H18). The graph bars on the material properties cards below compare 3105-H14 aluminum to: 3000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relev ...

why 3004 aluminum sheet with high quality? 3004 aluminum sheet belongs to AL-Mn series alloys and are the most widely used rust-proof aluminum. 3004 aluminum sheet has good forming, welding and corrosion resistance, excellent shape processing characteristics, good conductivity, smooth surface, good plasticity and pressure resistance, higher strength than 3003 aluminum sheet. The thickness of aluminum sheet ...

Color coated stucco aluminum plate also called as color coated embossed aluminum plate, the common seen embossed patterns on the surface are orange peel and rhombus/diamond pattern, the surface coating are fluorocarbon and polyester paint, the paint has various colors like white, black, red, green, blue, gray, yellow, gold and so on. The specification of color coated stucco embossed aluminum are:Alloys: 1050, ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...