what is Aluminum corrugated sheet? Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold- ...

How is embossed aluminum sheet produced Select aluminum material: first select the aluminum plate that meets the requirements. Commonly used aluminium materials include aluminum alloy plate, pure aluminum plate, etc., and their thickness is generally between 0.5mm-3mm. Surface treatment: The surface of the aluminium plate is cleaned, degreased, pickled, etc. to remove impurities such as oil and scale to e ...

How thick is 0.025 aluminum sheet? 0.025-inch aluminum plate refers to an aluminum plate with a thickness of 0.025 inches, which is approximately 0.635 mm. .025 aluminum sheet is an aluminum sheet belonging to the foil series (thickness less than 3mm). 0.025 aluminum sheet has the characteristics of light weight, corrosion resistance and good ductility, and has a very wide range of applications. 0.025 aluminum ...

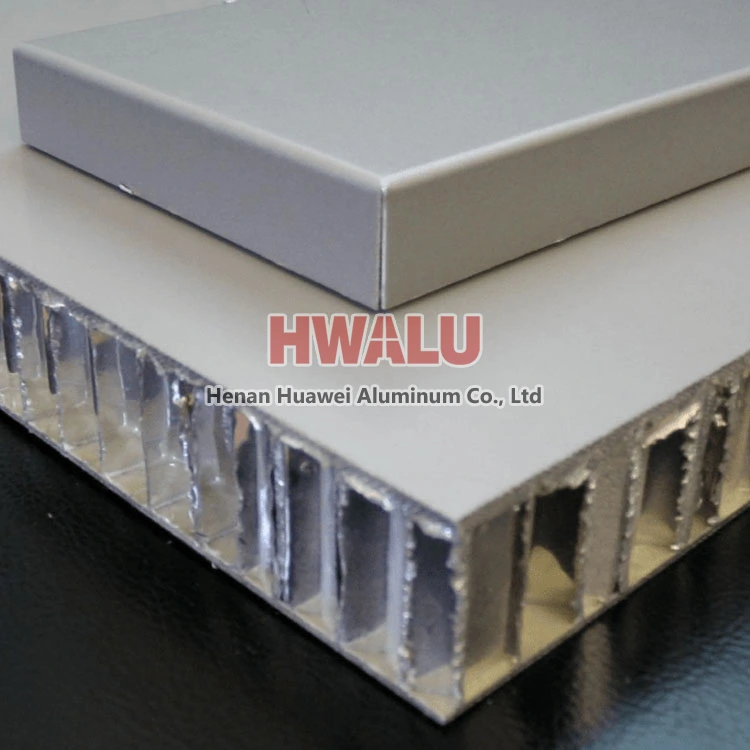

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

Introduction The thickness of a 1 16 aluminum sheet is exactly that—1/16 of an inch. In decimal terms, this is equivalent to 0.0625 inches. In millimeters, it translates to approximately 1.59 mm. It’s a commonly used thickness for a variety of applications due to its balance of flexibility and strength. The 1 16 aluminum sheet is a popular material choice across industries due to its versatility, durability, ...

What is 040 Aluminium Sheet The 040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material that is commonly used in various applications, including automotive, aerospace, construction, and industrial applications, as well as for general fabrication and DIY projects. Approximate search keywords of 040 Alu ...

Aluminum Alloy 6061 sheets are the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2000 and 7000 alloys, 6061 aluminum provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the ""O"" temper or annealed condition, alloy 6061 has good formability. In the T4 condition, fairly severe form ...

Aluminum alloy No. 1050, H stands for work hardening state, Hxx state description: The first digit 1 stands for simple work hardening state, suitable for the required strength without additional heat treatment, only work hardening. The second digit represents the hardened state, the number 0 represents the annealing, ie the soft state, 8 represents the hard state, 9 represents the super-hard state, and the number ...

Among the 1000 to 8000 alloy series, the 7000 series aluminum alloy is a heat treatable alloy, belonging to the aircraft series, and belongs to a relatively high-end field in aluminum sheets. The 7075 aluminum sheet is a representative product of the 7000 series, it is aircraft aluminum sheet with aluminum magnesium zinc copper alloy, can be heat treatable, has super hard ability and good wear resistance.7075 ...

5052-H32 Aluminum Sheet Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels th ...

Aluminum-manganese alloy mirror aluminum sheet 3003 has good performance in rust resistance and corrosion resistance. Anyone who knows mirror aluminum sheets knows that there are many specific varieties in terms of materials and crafts. From the material point of view, there are three main types, the pure aluminum mirror sheet, the Al-Mn aluminum mirror sheet and Al-Mg mirror aluminum sheet, among them, the al ...

6061 aluminum sheet is a popular material due to its strength, low weight, formability and resistance to moisture, heat and corrosion. 6061 aluminum sheet has an ultimate tensile strength of at least 42,000 psi and yield strength of at least 35,000 psi making it ideal for a wide range of applications. 6061 aluminum is the most widely used aluminum grade. 6063 is widely used as 6063 aluminum sheet plate and 606 ...