Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

What is Mirror Aluminum Sheet Mirror Aluminum Sheet refers to an aluminum sheet coil with a mirror effect on the surface of the sheet, created by rolling, polishing, and other methods. The reflectivity of such sheets can reach more than 86%, and for high reflective mirror aluminum sheets, it can reach more than 95%. Common alloys for mirror aluminum sheet coil include 1000 series, 3000 series, and 5000 se ...

What is the 95 reflective aluminum sheet? 95 reflective aluminum sheet refers to a mirror aluminum sheet with a reflectivity of 95%. The level of reflectivity determines the quality of the mirror reflective aluminum sheet. 95 mirror aluminum sheet refers to a mirror-like surface that is processed through rolling, polishing and other methods. Effect aluminum plate. Generally, mirror aluminum plates abroad use rol ...

The distinction of mirror reflective aluminum sheet There are many kinds of mirror reflective aluminum panels, ranging from low to high grades, including film mirror aluminum, domestic polished mirror aluminum, imported polished mirror aluminum, imported oxidized mirror aluminum, and super mirror aluminum. 040 mirror reflective aluminum sheet Aluminum mirror sheet production process The production proce ...

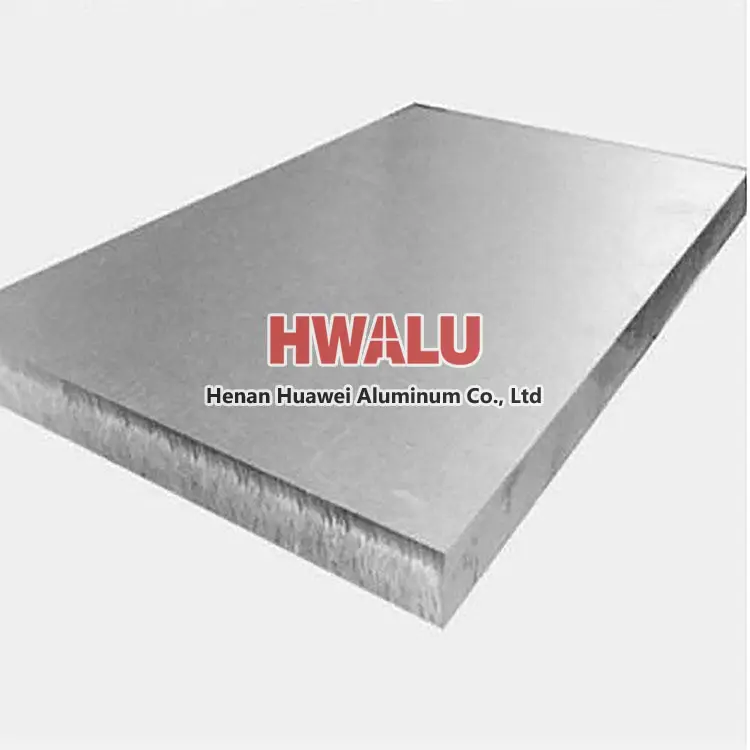

Super thickess aluminum plate refers to aluminium plates with thick between 200mm ~ 500mm. For example, the commonly used aluminum plate thicknesses are 200mm, 250mm etc

5083 aluminum sheet of Huawei Aluminum is belongs to the Al-Mg-Si alloy, the usage has a wide range, 5083 aluminum sheet plate is the most promising alloy. 5083 aluminum has good corrosion resistance, excellent weld-ability, good cold work-ability, and medium strength. The main alloy elements is magnesium, with good forming process-ability, so 5083 aluminum sheet usually used in the manufacture of aircraft fuel t ...

Both 5052-H32 aluminum and 5052-H34 aluminum are variants of the same material. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing. 6061 aluminum sheet alloy is strong, easily machined, and weldable. Aluminum 6061 T6 alloys are doubled the strength of aluminum 6063 alloys. Aluminum 6061 has an ultimate tensile strength of a ...

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the alum ...

Lightweight: Thin aluminum sheet is lightweight relative to other metal materials, making it ideal for many industries such as aerospace, automotive, construction, and packaging. Good processability: Thin aluminum sheet has excellent processability and can be easily bent, cut, welded, and formed. This makes it widely used in many industries, such as automotive, construction, and industrial production. S ...

1050 aluminum sheet has a place with 1000 series aluminum alloy metal. It has a place with an economically unadulterated created family with a virtue of close to 100% Al approx. Notwithstanding the part Al, 0.4% iron is added, so aluminum 1050 alloy has high conductivity. 1000 series aluminum bunch offers the best amendment obstruction contrasted with any composite gathering, so does the 1050 aluminum sheet. An a ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. 5052 aluminum sheet is often referred to as "Anodize Quality Aluminum", as it has excellent finishing qualities and anodized coatings are bright and clear. The major alloying element in 5052 is magnesium in sufficient quantities to caus ...