What does the 4x8 in the 4x8 foot aluminum plate mean? In general, 1'=1 foot (symbol ft) = 12 inches (12") = 30.48 cm = 304.8 mm 1"=1 inch ( inch is abbreviated as in or " ) = 2.54 cm = 25.4 mm (actual value is 2.539999918 cm.) So, 4 in 4 x 8 foot is 4 x 304.8 mm = 1219.2 mm = 1.2192 m ≈ 1220mm ≈ 1.22 m 8 in 4 x 8 feet is 8 x 304.8 mm = 2438.4 mm = 2.4384 meters ≈ 2440mm ≈ 2.44 m i.e. 4x8 foot = 1.22m ...

Introduction to 3004 aluminum sheet/plate? 3004 aluminum sheet is a non-heat-treatable aluminum alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 series also belongs to a series of aluminum manganese alloy. It has higher strength than 3003, exce ...

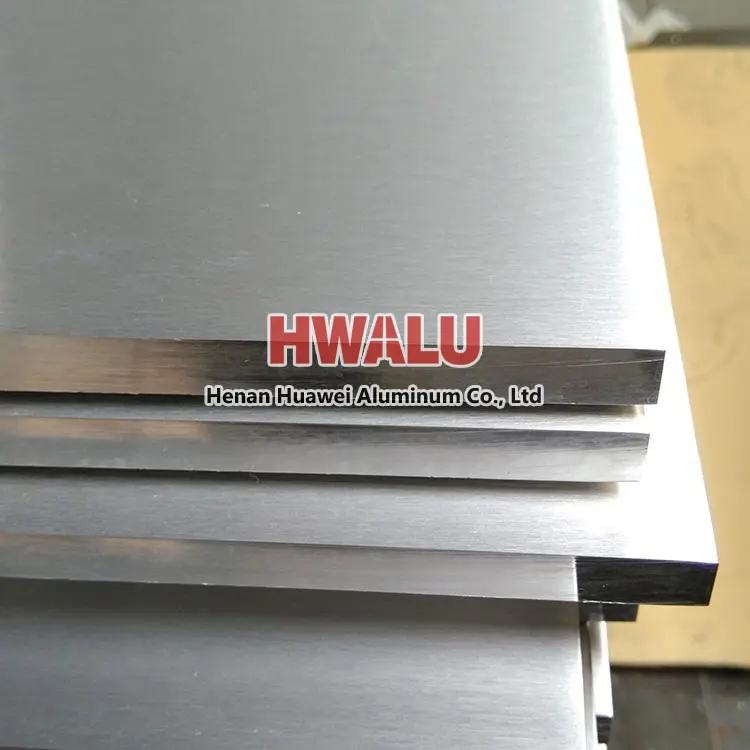

Medium thickess aluminum plate refers to aluminium plates with thick between 25mm ~ 200mm. Unit ( mm ): 25mm, 25.4mm, 26mm, 27mm, 28mm, 29mm, 30mm, 35mm, 40mm, 45mm, 50mm, 50.8mm, 100mm etc Unit ( cm ): 10 cm etc Unit ( inch ): 1, 2 etc

What is the 95 reflective aluminum sheet? 95 reflective aluminum sheet refers to a mirror aluminum sheet with a reflectivity of 95%. The level of reflectivity determines the quality of the mirror reflective aluminum sheet. 95 mirror aluminum sheet refers to a mirror-like surface that is processed through rolling, polishing and other methods. Effect aluminum plate. Generally, mirror aluminum plates abroad use rol ...

Premier 2mm Aluminum Sheet Provider--huawei aluminum At Huawei Aluminum, we pride ourselves on being the leading provider of high-quality aluminum sheets, offering a diverse range of alloy models and specifications tailored to meet the needs of our global clientele. With state-of-the-art manufacturing facilities and a commitment to innovation and customer service, we ensure that every 2mm aluminum sheet we produ ...

3005 Aluminum sheet overview 3005 alloy metal aluminum sheet plate belons to aluminium sheet 3xxx series. The strength of 3005 al-mg aluminum plate is about 20% higher than that of 3003 aluminum plate, and corrosion resistance is also better.Also known as anti-rust aluminum plate. 3 series aluminum plate is mainly composed of manganese, with the content between 1.0 and 1.5.It is a series with better anti-rust ...

Aluminium sheet plate in aerospace applications.Aircraft-grade aluminium sheet plate are mainly used to produce aircraft fuselage, wing, tail wing and skins. These parts are usually directly milled using a high-strength aluminium plate to reduce manufacturing costs, reduce body weight and facilitate management. If the aluminium plates are not thick enough, these large parts cannot be cut at all. The thickest alum ...

The 7075 aluminum sheet is a product that is frequently used because of its strength, toughness and corrosion resistance. It is in fact one of the strongest aluminum alloys out there. Its weight-to-strength allows it to be used for high stressed parts. In the annealed condition, the 7075 aluminum can be formed using heat methods. It’s not good with cold working. Once formed, it’s recommended that heat treatment b ...

What are the main application of the 1060 aluminum sheet metal in 1000 series aluminum? First is signs, billboards. In view of the light weight, easy processing, corrosion resistance and rust resistance of aluminum sheet, it is currently the most important material for making billboards, signs and road signs; The second is interior decoration materials, at present, many high-grade wall panels, indoor ceilings ...

Aluminum mirror sheet is the aluminum sheet processed by rolling, polishing and other methods to make its surface appear like a mirror. With the development of science and technology, aluminum mirror sheet have more and more widely applications in our daily life. The application of aluminum mirror sheet is very extensive. Aluminum mirror sheet is widely used in lighting lamps and lanterns reflective panels and ...

3105-H14 aluminum is 3105 aluminum in the H14 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly halfway between annealed (O) and full-hard (H18). The graph bars on the material properties cards below compare 3105-H14 aluminum to: 3000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relev ...

Aluminum is one of the metals most widely used in industry and daily life, when it comes to the aluminum alloy, the 1000 series aluminum sheet come to our mind, there are two typical aluminum sheet in 1000 series aluminum sheet alloy, they are 1050 aluminum sheet and 1060 aluminum sheet, they are all with high content of aluminum, they looks like the same, but their types are different, what is the difference bet ...