Thin aluminum sheet refers to aluminium sheets with thick between 0.15mm ~ 2mm. The parameters of 5052 thin aluminum plate as an example are for reference only. If you want to know more about the thin aluminum plate, please contact us as soon as possible. Alloy State Thickness Width Tensile strength (Mpa) Elongation (δ%)(Scaling distance 50) 5052 0 >0.5~1.3 >1.3~4.5 Above 500mm ...

Welcome to Huawei Aluminum, your trusted manufacturer and wholesaler of high-quality 16 gauge aluminum sheets. Our products are designed to meet a wide range of industrial and architectural needs, offering durability, strength, and versatility. Introduction 16 gauge aluminum sheets are widely used in various applications such as construction, automotive, aerospace, and marine industries. They are known for thei ...

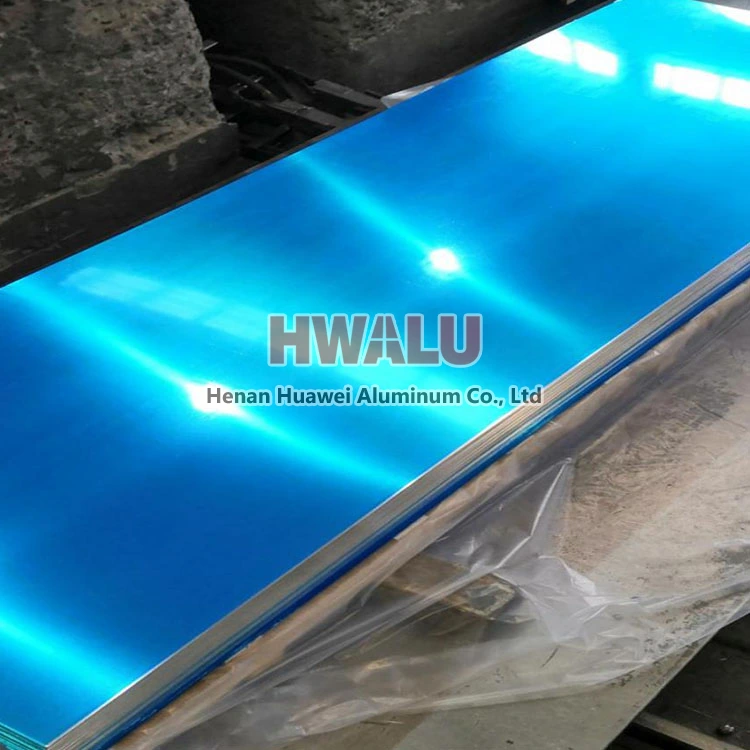

Aluminum sheet plate refers to aluminum material with width of 200mm over, and length of less 16000m. Custom Sizes 1 foot = 12 inch = 304.8 mm, 4 feet = 48 inches = 1220 mm Unit ( foot ): 4x4, 4x6, 4x8, 4x10, 4x12, 5x8, 6x8 etc Unit ( inch ): 12x12, 24x24, 24x36, 24x48, 36x36, 48x48 etc Hot sales sizes 4x8 foot aluminum sheet plate 5x8 ft ( 5 x 8 ), 60x96 inch ( 60 x 96 ), 1524 x 2438.4mm ...

What does the 4x8 in the 4x8 foot aluminum plate mean? In general, 1'=1 foot (symbol ft) = 12 inches (12") = 30.48 cm = 304.8 mm 1"=1 inch ( inch is abbreviated as in or " ) = 2.54 cm = 25.4 mm (actual value is 2.539999918 cm.) So, 4 in 4 x 8 foot is 4 x 304.8 mm = 1219.2 mm = 1.2192 m ≈ 1220mm ≈ 1.22 m 8 in 4 x 8 feet is 8 x 304.8 mm = 2438.4 mm = 2.4384 meters ≈ 2440mm ≈ 2.44 m i.e. 4x8 foot = 1.22m ...

8000 Series Aluminum Sheet Overview Features: It belongs to aluminum-lithium alloy, and its main component is lithium, because lithium is the lightest metal in nature. When lithium is added to the aluminum sheet, it can effectively reduce the ratio of aluminum sheet, while ensuring the strength of the aluminum sheet. Purpose: Aluminum plates with bottle caps as the main function are also used in radiators, ...

What is the thickness of 3/16 thick aluminum plate? The thickness of the aluminum 3/16 plate is expressed in millimeters: 1 inch = 25.4mm 25.4*3/16 = 4.7625 3/16 inch = 4.7625 mm The thickness of 3/16 sheet aluminum is expressed in feet: 1 foot = 12 inches 3/16 inch = 0.015625 feet 3 16 thick aluminum sheet How to calculate the weight of 3 16 aluminum sheets per unit area? 3 16 alumi ...

The 5052 h34 aluminum sheet is highly resistant to corrosion. It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments without worry of corrosion. This metal also has excellent thermal conductivity and low density, which is commonly found with other ...

Low stocks have limited impact in the off-season, and aluminum prices are expected to fluctuate strongly in August Source: SMM SMM News on August 4th: Aluminum prices have almost risen continuously since the beginning of the second quarter. The gravity center of aluminum futures in July has continued to move upward. Although July 16 recorded the largest daily decline since April, it is supported by fundamentals. ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

5005 h24 aluminum alloy is an aluminium alloy with good resistance to atmospheric corrosion.It is used in decorative and architectural applications. It is a member of the 5000 series of aluminum-magnesium wrought alloys. As such, it is not used in casting. It can attain moderate to high strength by cold working, and has relatively high welded strength compared to other aluminum alloy families. Tempers H116 and H3 ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

Aluminium 5083 alloy for boat has been used in the ship building industry for nearly 100 years. With the rapid development of the shipbuilding industry at home and abroad, the lightweight of ships like sailboat has been paid more and more attention. Due to the low density, ships constructed from marine grade aluminum are 15-20% lighter than ships constructed from steel or other synthetic materials, which is a ...