1050 metal aluminum sheet plate belongs to a commercially pure wrought family with a purity of 99.5% Aluminium( over 99.0% ). Except for Al, 0.4% of Fe is added to 1050 aluminum plates, thus, they have high electrical conductivity. 1000 series aluminum group offers the best correction resistance compared to any alloy group, and so does the 1050 aluminum sheet. 1050 aluminum sheet, temper O~H112, thickness ...

What is hot rolling? Hot rolling generally refers to rolling above the recrystallization temperature of the metal. During the hot rolling process, the metal deformation has both hardening and softening processes. Due to the influence of the deformation speed, as long as the recovery recrystallization process is too late, the metal will have a certain degree of work hardening with the increase of the deformation ...

Introduction Welcome to Huawei Aluminum, your leading provider of high-quality reflective aluminum lighting sheets. With years of expertise and dedication to innovation, we deliver superior products tailored to meet the diverse needs of our clients across various industries. Our reflective aluminum lighting sheets are designed to offer unmatched durability, reflectivity, and efficiency, catering to your specific ...

What is 1 8 aluminum checker plate Aluminum checker plate, also known as aluminum tread plate or aluminum diamond plate, is a type of metal sheet with a raised pattern of lines or diamonds on one side. The pattern provides increased traction and durability, making it ideal for use in industrial and commercial applications where slip resistance is important. 1 8 aluminum checker plate refers to a specific ...

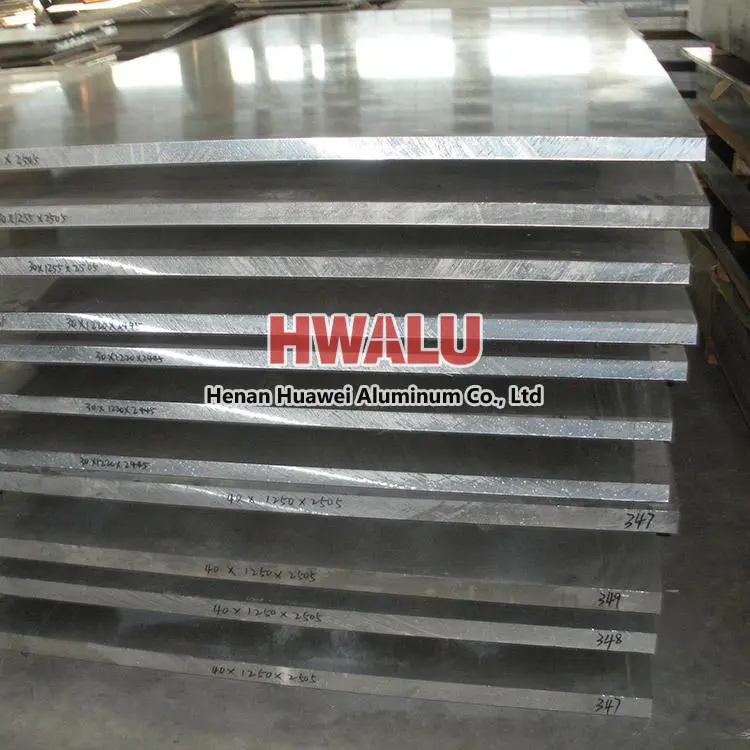

Aluminum sheet plate refers to aluminum material with width of 200mm over. Standard width: 1000mm, 1200mm, 1220mm etc 4x4 ft ( 4 x 4 ), 48x48 inch ( 48 x 48 ), 1219.2 x 1219.2 mm 4x6 ft ( 4 x 6 ), 48x72 inch ( 48 x 72 ), 1219.2 x 1828.8 mm 4x8 ft ( 4 x 8 ), 48x96 inch ( 48 x 96 ), 8x4 ft ( 8 x 4 ), 1219.2 x 2438.4 mm 4x10 ft ( 4 x 10 ), 48x120 inch ( 48 x 120 ), 1219.2 x 3048 mm 4x12 ft ( 4 x ...

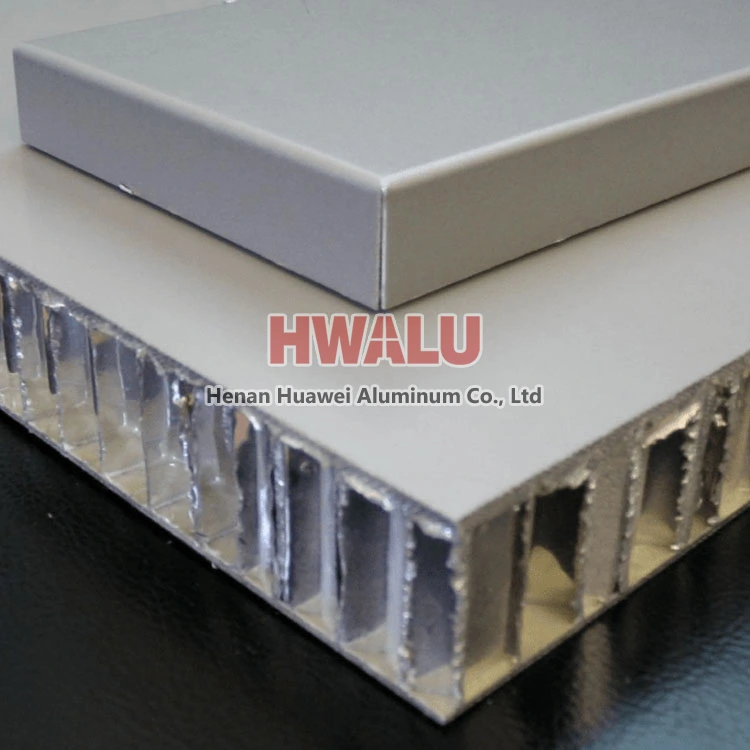

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

6082 aluminum alloy is another typical alloy of 6000 series aluminum, the common product are 6082 aluminum sheet and 6082 aluminum bar. Today we are going to talk about the first model- 6082 aluminum sheet. As we have in mind, 6000 series aluminum have Mg and Si as the main alloy besides Al, and 6000 series aluminum alloy is the most widely used aluminum product. So what are the features and application of 608 ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

The 5005 aluminum sheet price on the market is affected by the specification and usage. As one alloy in 5000 series aluminum, 5005 aluminum is not as famous as 5052, 5083 and 5086 aluminum. But 5005 aluminum sheet also have many application in the industry, it is used as conductor, cookware, instrument panel, lighting, instrument case and architectural decoration, high-end curtain wall board, etc.The 5005 alum ...

6061 aluminum sheet plate and 6063 aluminum sheet plate are both belong to the 6000 series aluminum alloy, they are similar but still have difference. The main alloying elements of 6061 and 6063 aluminum alloy are magnesium and silicon. 6061 aluminum has more alloy elements content than 6063 aluminum. With excellent processing performance, excellent weldability, extrusion and electroplating, good corrosion res ...

3004 aluminium alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose allo ...

5754 aluminum sheet belongs to Al-Mg-Si aluminum alloy, it has a wide range of applications in the field of high-level aluminum processing industry. With the vigorous development of the railway transport market, and the globalization of automobile era, processing needs of aluminum marine sheet plate, rail transportation, high-grade car complex parts is increasing, 5754 alloy has great market prospect. 5754 Alu ...