What is brushed aluminum sheets

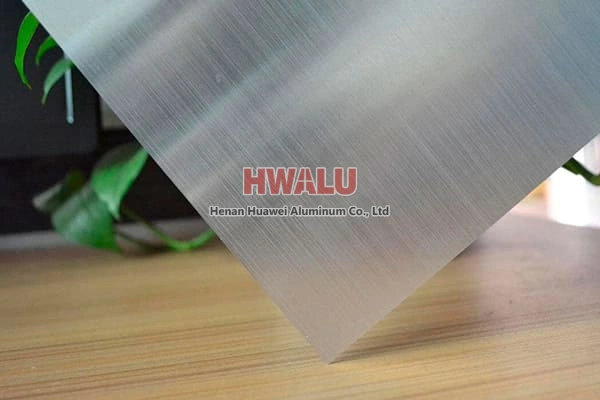

Brushed aluminum sheets are aluminum sheets that have a brushed finish applied to them. This finish is achieved by mechanically brushing the surface of the aluminum with a fine abrasive material. The brushing process creates a distinctive pattern of fine lines on the surface, giving the aluminum a stylish, modern look.

Brushed aluminum sheets are commonly used in interior and exterior architectural applications, as well as in the automotive industry and for signage. The brushed finish not only adds a decorative element but also helps to mask scratches and fingerprints, making it a popular choice for high-traffic areas.

Advantages of using brushed aluminum sheets

1. Anti-corrosion

Due to various surface treatments, the brushed aluminum plate can effectively prevent oxidation and extend its service life. At the same time, the surface of the brushed aluminum sheet is smooth, has good anti-fouling properties, and is not easy to adhere to dust, stains, etc.

2. Wear resistance

The surface of the brushed aluminum sheet is brushed to make it more wear-resistant. Due to the drawing treatment, tiny scratches are produced on the surface of the aluminum plate, making the surface of the aluminum plate more uniform and smooth. In addition, brushed aluminum plates have higher hardness and strength and have better resistance to extrusion.

3. Anti-fingerprint

The high-quality brushed aluminum plate has an amazing anti-fingerprint effect. Fingerprints remain on the surface and can be easily wiped off with a dry cloth or paper towel.

4. Beautiful

The surface of the brushed aluminum sheet shows a delicate brushed texture, which shows an alternating effect of light and dark under the sun, making it particularly beautiful. Moreover, the brushed aluminum sheet can be customized in different colors, thicknesses, and sizes according to needs, and has high plasticity.

5. Environmental protection

The brushed aluminum plate is non-toxic and odorless and meets environmental protection standards. At the same time, aluminum is highly recyclable and can effectively reduce environmental pollution.

What is brushed aluminum used for?

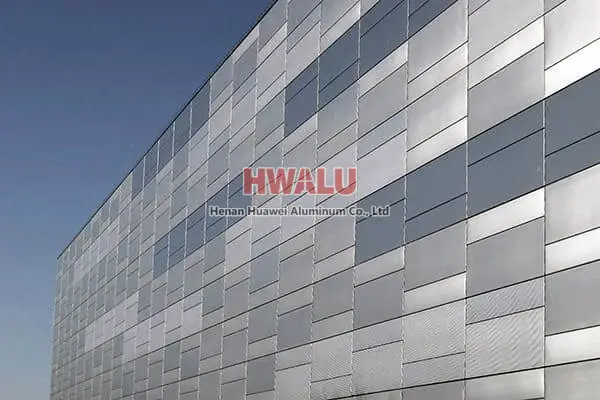

- 1. In the construction field, brushed aluminum sheets are widely used in exterior wall decoration, roofs, ceilings, partitions and facades. Its unique brushed texture and metallic texture give the building a modern feel and temperament.

- 2. In the field of transportation, brushed aluminum sheets are often used in the field of transportation to manufacture the shells and interiors of vehicles such as ships, cars, trains, and airplanes. It is lightweight, corrosion-resistant and pressure-resistant, and can effectively improve the performance and safety of transportation.

- 3. Home decoration field Brushed aluminum sheets are widely used in the home decoration field to make furniture, cabinets, doors and windows, and electrical appliance casings. Its surface has been brushed, giving it a stylish and stylish appearance that can enhance the quality and taste of your home environment.

- 4. Electronic field Brushed aluminum sheets are often used in the electronic field to manufacture casings and radiators for electronic products such as computers, mobile phones, and flat-screen TVs. It has good electrical conductivity and can effectively dissipate heat to ensure the normal operation of electronic equipment.

- 5. Packaging field Brushed aluminum sheets are often used in the packaging field to manufacture packaging boxes and bottle caps for products such as food, pharmaceuticals and cosmetics. Its surface is smooth and easy to clean, which can effectively protect the quality and safety of products.

How do you brush aluminum sheets?

Preparation: Start with a clean, flat aluminum sheet. Ensure that the surface is free of any dirt, oil, or other contaminants.

Brushing Machine: Use a brushing machine designed for metal finishing. This machine typically consists of abrasive brushes that rotate or move back and forth over the surface of the aluminum.

Brushing Process: The aluminum sheet is fed through the brushing machine, where the abrasive brushes create the brushed finish. The pressure, speed, and direction of the brushes can be adjusted to achieve the desired finish.

Pattern and Finish: The pattern of the brushed finish depends on factors such as the type of abrasive brushes used, the pressure applied, and the speed of the brushing process. Common patterns include straight lines or circular patterns.

Quality Control: Inspect the brushed aluminum sheet to ensure that the finish is uniform and meets the desired quality standards. Adjustments to the brushing process may be needed to achieve the desired result.

Different finishes of brushed aluminum sheets

Directional Brushed Finish: This finish features straight, uniform lines that are typically brushed in one direction. It provides a clean, modern look and is often used in architectural applications and furniture.

Circular Brushed Finish: In this finish, the brushing pattern consists of circular or swirling lines. It offers a more dynamic appearance compared to the directional brushed finish and is often used for decorative purposes.

Cross Brushed Finish: This finish combines both directional and circular brushing patterns, creating a cross-hatched appearance on the surface of the aluminum. It offers a unique and textured look that can add depth to the material.

Random Brushed Finish: As the name suggests, this finish features a random pattern of brush strokes, resulting in a more organic and natural look. It is often used in artistic and creative applications.

Satin Finish: A satin finish is a smooth, non-reflective finish that is achieved by using fine abrasives to create a soft, matte appearance. It is often used in applications where glare needs to be minimized.

Bright Brushed Finish: This finish is achieved by using finer abrasives and higher pressure during the brushing process, resulting in a brighter, more reflective surface compared to other brushed finishes. It is often used in decorative applications where a shiny finish is desired.

Using brushed aluminum sheets in architecture and construction

Brushed aluminum sheets are widely used in construction applications, such as exterior wall decorative panels, curtain wall panels, ceilings, etc.

There are huge advantages to using brushed aluminum sheets in construction.

First of all, the density of brushed aluminum sheets is low, which can effectively reduce the weight of decorative panels and reduce the burden on structural parts.

Secondly, aluminum plates have strong corrosion resistance, and decorative brushed sheets can extend their service life.

Finally, the use of brushed aluminum panels can improve the aesthetics of the building, is easier to care for than mill finish aluminum panels, and is less likely to leave fingerprints.

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

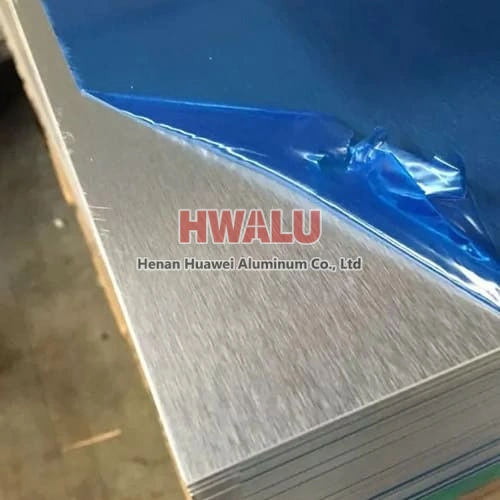

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;