What is reflective aluminum sheet?

What is aluminum sheet reflector? Reflective aluminum sheet, also known as mirror aluminum sheet or reflective aluminum, is a type of aluminum sheet. It has reflective surfaces that reflect light and heat. It has high reflectivity, also known as high reflective aluminum sheet. Reflective aluminum sheet refers to a thin and flat aluminum material that has been specially treated or coated to improve its reflective properties.

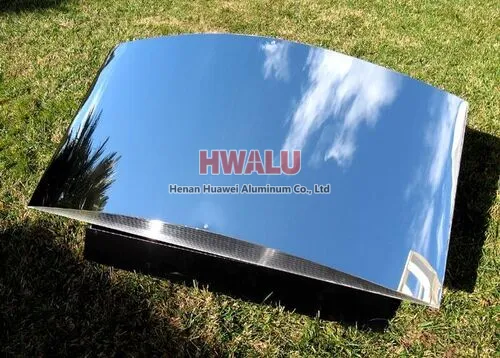

aluminiun-reflector-sheet

aluminiun-reflector-sheet

Reflective aluminum sheet reflectivity

The reflectivity of a mirror aluminum plate refers to the ability of the surface of the aluminum plate to reflect incident light, usually expressed as a percentage. The reflectivity of mirror aluminum panels depends on its surface quality and manufacturing process. The reflectivity of reflective aluminum panels is very high, mainly due to the special structure of its surface. Its surface is polished to a very smooth mirror surface. When light hits the surface of the aluminum plate, reflection occurs. Because aluminum has good electrical conductivity, it can quickly conduct light to the inside of the aluminum plate, and then through internal reflection, the light can be emitted again. This series of reflection processes makes the specular reflective aluminum plate have a very high reflectivity.

Generally, the reflectivity of high-end mirror aluminum plates can reach more than 90%, and can even reach the reflectivity of super mirror 95%. Huawei Aluminum can supply aluminum plates with a reflectivity of over 90%. These highly reflective aluminum panels typically have a very smooth surface that is precision polished and machined to ensure optimal reflection of light.

Reflective aluminum sheet equivalent name

| Reflective aluminum plate |

mirror aluminum sheet |

reflective aluminum sheet |

| mirror reflective plate |

reflective aluminum plate |

mirror polished aluminum plate |

Reflective aluminum sheet alloy

Reflective aluminum panels are usually made of high-quality aluminum alloy and treated to enhance their reflective properties. The most commonly used alloys for reflective aluminum plates are 1000 series: 1050, 1060, 1070, 1100.

5000 aluminum plate series: 5052, 5083.

5052 high reflective aluminum sheet

Alloy 5052 is a versatile alloy with a good balance of properties, making it a popular choice for a variety of applications where high reflectivity and other properties are important.

5052 alloy reflective aluminum plate is a non-heat treatable aluminum alloy with good corrosion resistance, formability and high strength. It is commonly used in applications requiring high reflectivity, such as lighting fixtures, solar panels and decorative mirrors. To enhance the reflectivity of aluminum sheets, 5052 alloy sheets can be given a high-quality surface treatment. The reflective properties of the mirror 5052 aluminum plate can be improved through processes such as polishing, anodizing or coating.

Reflective-aluminum-sheet

Reflective-aluminum-sheet

Application of mirror aluminum plate

Specular reflective aluminum is an aluminum material that has been treated or coated to enhance its reflective properties. This treatment enables the aluminum surface to effectively reflect light and heat, making it ideal for applications requiring high reflectivity, such as lighting fixtures, solar collectors, decorative materials, electronics, and more. .

. These sheets are commonly used in a variety of applications where high reflectivity is required, such as:

1. Solar panels: Reflective aluminum panels are used as backing materials for solar panels, helping to maximize the reflection of sunlight onto solar cells, thus improving the overall efficiency of the panels.

2. Lighting fixtures: Reflective aluminum plates are used in lighting fixtures to enhance light distribution and reduce glare by reflecting and redirecting light to specific directions.

3. Mirrors: Reflective aluminum panels can serve as a cost-effective alternative to traditional glass mirrors in certain applications where weight or cost constraints are a concern.

Reflective aluminum sheet supplier

Mirror-polished aluminum plate is one of the commonly used materials in solar thermal power stations. Highly reflective mirror anodized aluminum from Huawei Aluminum. Through the vacuum magnetron sputtering process and German continuous roll-to-roll vacuum coating equipment, based on electronic evaporation aluminum technology, a layer of metallic aluminum is coated on it as a reflective layer. Then a protective layer of titanium dioxide and silicon dioxide is coated on it to form a highly reflective mirror aluminum material with a reflectivity of up to 95%±1%. The width of the high-reflective mirror aluminum sheet is less than or equal to 1250mm, and the thickness is between 0.3mm-1.0mm. The shipping package is packed in rolls for easy transportation, and the mirror is covered with plastic film to protect the mirror from damage.

Is aluminum sheet a good light reflector?

Aluminum is an excellent light reflector due to its high reflectivity properties. Aluminum is highly reflective of both visible and infrared radiation, making it a popular choice for applications that require efficient reflection of light. Aluminum’s high reflectivity allows it to effectively reflect and redirect light, making it ideal for a variety of applications.

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;