0.5mm aluminum sheet brief description

0.5mm aluminum sheet is a common metal material in industry and manufacturing. Its basic feature is that it is a rectangular plate with a thickness of 0.5mm, which is rolled and processed from aluminum or aluminum alloy. Aluminum sheets of this thickness are lightweight, highly corrosion-resistant, have good electrical and thermal conductivity, and are widely used.

Advantages of using 0.5mm aluminum sheet

- 1. Lightweight: The density of aluminum is small. An aluminum plate with a thickness of 0.5mm is much lighter than other metal materials such as steel plates of the same area. It is significant for areas that need to reduce weight, such as aerospace, automobile manufacturing, building materials, etc. advantage.

- 2. Good processability: Aluminum has good plasticity and ductility. Aluminum plates with a thickness of 0.5mm can easily undergo various mechanical processing such as bending, stamping, cutting, and welding, adapting to complex structural design and modeling requirements.

- 3. Corrosion resistance: Aluminum itself has good resistance to atmospheric corrosion. Through anodization or surface treatment technology (such as spraying, coating, etc.), its corrosion resistance can be further enhanced and its service life extended. It is especially suitable for outdoor and humid environments. usage of.

- 4. Aesthetics and diversity: Aluminum panels can be surface treated in a variety of ways to produce rich color and texture effects to meet different decorative and aesthetic needs.

- 5. Rapid construction and installation: Thin aluminum plates are easy to transport and install, especially prefabricated products that can be assembled directly on site to improve construction efficiency.

- 6. Environmental protection and recyclability: Aluminum is a material that can be completely recycled and reused, and the energy consumption during the recycling process is relatively low, which is in line with the concept of sustainable development.

- 7. Thermal insulation: When the 0.5mm aluminum sheet is used as part of the thermal insulation composite material, for example, it is combined with the thermal insulation material to form an integrated thermal insulation board, which can provide good thermal insulation performance while maintaining structural strength.

- 8. Electrical and thermal conductivity: Aluminum has excellent electrical and thermal conductivity, and is suitable for applications such as electrical equipment and radiators that require heat dissipation.

Applications of 0.5mm aluminum sheet

| Application |

Description |

| Electronics |

Used in manufacturing electronic components and enclosures. |

| Home Appliances |

Components for various home appliances. |

| Cookware |

Lightweight cookware items. |

| Building and Construction |

– Siding: Panels for building exteriors.

– Gutters: Used in gutter systems.

– Roofing: Durable roofing material.

– Awnings and Carports: Lightweight structures. |

Understanding the properties of 0.5mm aluminum sheet

Easy processing: After adding certain alloy elements, cast aluminum alloy has good casting performance, while deformed aluminum alloy has good processing plasticity.

Good electrical and thermal conductivity: Aluminum’s electrical and thermal conductivity is second only to silver, copper and gold.

Low density: The density of aluminum and aluminum alloys is close to 2.7g/cm³, which is about 1/3 of iron or copper.

High strength: After a certain degree of cold working, the strength of aluminum and aluminum alloys can be strengthened.

Good corrosion resistance: A dense AL2O3 protective film is easily formed on the surface of aluminum, effectively protecting the substrate from corrosion.

Different types of 0.5mm aluminum sheet available in the market

Aluminum sheets come in various types, each with distinct properties and applications. Let’s explore some of the common types of 0.5mm aluminum sheet available:

**0.5mm Standard Aluminum Sheet**

- – Lightweight, corrosion-resistant, and ductile.

- – Suitable for applications where weight reduction is essential (e.g., automobile production).

- – Easy to bend or shape.

- – Not mirror-surfaced but light reflective.

**0.5mm Checkered Plate Aluminum Sheet**

- – Features a five-bar pattern.

- – Strong, corrosion-resistant, and slip-resistant.

- – Often used for flooring applications.

**Stucco 0.5mm Aluminum Sheet**

- – Has a pebble-like design.

- – Offers increased durability.

- – Less light reflective than other options.

**Color-coated 0.5mm Aluminum Sheet**

- – Many colors

- – Improve the aesthetics of materials

**Anodized 0.5mm Aluminum Sheet**

- – Improve the corrosion resistance of aluminum plates

- – Higher gloss, improving product aesthetics

- – Mostly used in electronic product casings

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

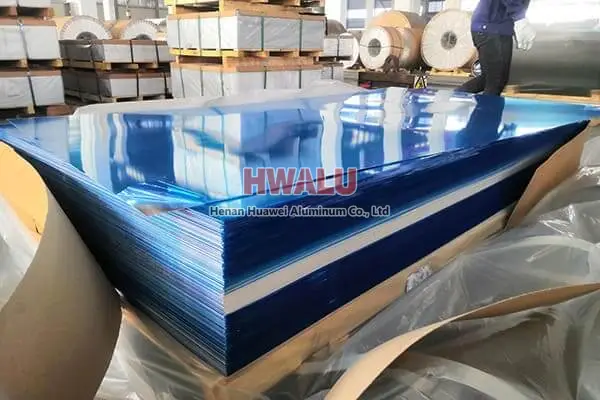

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;