1100 aluminum sheet plate overview

1100 aluminum sheet plate belongs to 1xxx series aluminum sheet, which is one of the softest aluminum alloys, so it is not used for high strength or high pressure applications. Although pure aluminum is usually cold-worked, it can also be hot-worked, but it is more common that aluminum is formed through spinning, stamping, and drawing processes that do not require the use of high heat. These processes produce aluminum profiles in the form of foils, plates, round bars, sheets, strips and wires.

Aluminum 1100 can also be welded; resistance welding is possible, but it can be difficult and usually requires the attention of a skilled welder. Aluminum 1100 is just one of several common aluminum alloys. It is soft, low-strength, and the smallest aluminum at 99% is commercial pure aluminum. Copper, iron, magnesium, manganese, silicon, titanium, vanadium and zinc constitute the remaining elements. It cannot be hardened by heat treatment and is very formable.

1100 metal pure aluminum sheet plate

1100 aluminum alloy is ordinary industrial pure aluminum with 99.0% aluminum content. It cannot be strengthened by heat treatment; the strength is low, but it has good ductility. Formability, weldability and corrosion resistance; after anodic oxidation, the corrosion resistance can be further improved while obtaining a beautiful surface.

1100 aluminum sheet is the most commercially pure alloy of all the aluminium grades. 1100 aluminium coil and 1100 aluminium sheet are both available for various applications including chemical storage and processing equipemtn. Benefits of 1100 aluminium coil & sheet include a 99% or greater content of aluminium compared to other grades of aluminium. 1100 is a low strength aluminium alloy with excellent corrosion resistance. This grade is best used for welding, brazing and soldering but has poor machinability. 1100 aluminium has great finishing capabilities so it is a great choice for decorative purposes.

1100 aluminum sheet parameters

Equivalent name

a1100, 1100a, aa1100, 1100aa, al1100, al1100a, 1100 aa, aa 1100, jis a1100p, al1100 class, aw1100 grade etc

Temper

Soft HO, H11, H12, H13, H14, H15, H16, H17, H18, H19, H20, H21, H22, H23, H24, H25, H26, H27, H28, H29, H30, H31, H32, H33, H34, H35, H36, H37, H38, H39, H46, H111, H112, H114, H116, H131, H321 etc

Thickness: ( thin) 0.18mm, 0.5mm, 0.8mm, 1mm, 1.5mm, 1.8mm, 2mm, 3mm, 3.8 mm, 4mm, 8mm ( thick ) etc

Size: 4ft x 8ft etc

Surface treatment: anodized, colored coated, embossed etc

Chemical composition of 1100 aluminum sheet

| Si ( Silicon ) |

Cu ( Copper ) |

Mg ( Magnesium ) |

Zn ( Zinc ) |

Mn ( Manganese ) |

Cr ( Chromium ) |

Fe ( Iron ) |

Ti ( Titanium ) |

Other |

Others total |

Al ( Aluminum ) |

| ≤ 0.95 |

≤ 0.05 |

≤ 0.05 |

≤ 0.1 |

≤ 0.05 |

/ |

≤ 0.4 |

/ |

≤ 0.05 |

≤ 0.15 |

remainder |

Properties of 1100 aluminum flat plates

| Alloy Temper |

Specified |

Tensile strength |

Yield strength |

Elongation |

| Thickness(in.) |

(ksi) |

(ksi) |

(%) |

| 1100-O (annealed) |

0.006-0.019 |

11.0-15.5 |

Min3.5 |

Min15 |

| 0.020-0.031 |

Min20 |

| 0.032-0.050 |

Min25 |

| 0.051-0.249 |

Min30 |

| 0.250-3.000 |

Min28 |

| 1100-H12/1100-H22 |

0.017-0.019 |

14.0-19.0 |

Min11.0 |

Min3 |

| 0.020-0.031 |

Min4 |

| 0.032-0.050 |

Min6 |

| 0.051-0.113 |

Min8 |

| 0.114-0.499 |

Min9 |

| 0.500-2.000 |

Min12 |

| 1100-H14/1100-H24 |

0.009-0.012 |

16.0-21.0 |

Min14.0 |

Min1 |

| 0.013-0.019 |

Min2 |

| 0.020-0.031 |

Min3 |

| 0.032-0.050 |

Min4 |

| 0.051-0.113 |

Min5 |

| 0.114-0.499 |

Min6 |

| 0.500-1.000 |

Min10 |

| 1100-H16/1100-H26 |

0.006-0.019 |

19.0-24.0 |

Min17.0 |

Min1 |

| 0.020-0.031 |

Min2 |

| 0.032-0.050 |

Min3 |

| 0.051-0.162 |

Min4 |

| 1100-H18/1100-H28 |

0.006-0.019 |

Min22.0 |

– |

Min1 |

| 0.020-0.031 |

Min2 |

| 0.032-0.050 |

Min3 |

| 0.051-0.128 |

Min4 |

| 1100-H112 |

0.025-0.499 |

Min13.0 |

Min7.0 |

Min9 |

| 0.500-2.000 |

Min12.0 |

Min5.0 |

Min14 |

| 2.001-3.000 |

Min11.5 |

Min4.0 |

Min20 |

Applications of 1100 aluminium plain sheets

1100 aluminum sheet is mostly used for some parts which require good forming and processing properties, high anti-corrosion, but low strength, such as video, the transportation and storage equipments of chemical products, metal sheet products, the processing of drawing spinning hollow goods, welding key combination, reflector and nameplat, etc. 1100 aluminum sheet is widely used in various fields from cooking utensils to industrial equipment, such as heat sinks, caps, printing sheets, building materials, heat exchanger components, it can also be used as deep-draw stamping products.

Cold rolled is the most commonly used forming method for aluminum 1100. A cold metal working process is any metal forming or forming process performed at or near room temperature. Aluminum 1100 can be processed into many different products, including chemical equipment, railroad tank cars, shark fins, dials, nameplates, cookware, rivets, reflectors, and metal plates. The plumbing and lighting industries also use aluminum 1100, as do many other industries.

Kitchen utensils ( cooker ), building materials, heat exchangers etc.

- 1100 plain alu sheet raw material for perforated sheet

- 1100 al sheet plate for aluminium gusset plate

- 4ft 1100 aluminum sheet for kitchen utensils

- Color coating 1100 aluminum sheet for building materials

- Heat exchangers

- 1100 aluminum sheet for bus body

- 1100 thermal insulation aluminum plate

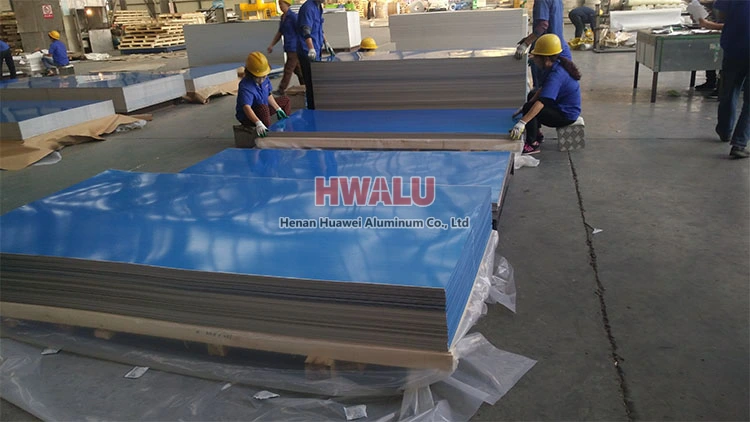

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;