Definition of 4mm aluminum sheets A 4mm aluminum sheet, also known as an aluminum plate, is a panel of aluminum that is 4 millimeters thick. It’s a result of basic raw-form aluminum being pressed and rolled into panel form under high pressure. Aluminum sheets are characteristically manufactured to be very thin and lightweight, yet sturdy enough to offer extreme versatility alongside inherent ease of installat ...

What are the two types of aluminum anodizing? There are two main types of aluminum anodizing: sulfuric acid electrolytic oxidation and hard anodizing. Sulfuric acid electrolytic oxidation is a conventional anodic oxidation method, which uses sulfuric acid as the electrolyte to form an oxide film on the surface of aluminum by means of electricity. This oxide film has certain protective and decorative propertie ...

Introduction The thickness of a 1 16 aluminum sheet is exactly that—1/16 of an inch. In decimal terms, this is equivalent to 0.0625 inches. In millimeters, it translates to approximately 1.59 mm. It’s a commonly used thickness for a variety of applications due to its balance of flexibility and strength. The 1 16 aluminum sheet is a popular material choice across industries due to its versatility, durability, ...

What is 4x8 diamond plate aluminum sheets A 4x8 diamond plate aluminum sheet is a standard-sized sheet of aluminum that has been embossed with a diamond pattern. The dimensions of the sheet are 4 feet by 8 feet. Advantages of using 4x8 diamond plate aluminum sheets 4x8 diamond plate aluminum sheets have several advantages that make them a popular choice for various applications: 1. Skid-resistance: Th ...

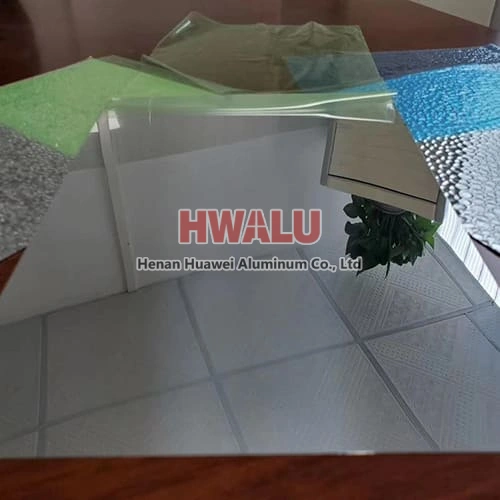

What is reflective aluminum sheet for lighting Reflective aluminum sheets for lighting are typically made from high-quality aluminum with a highly reflective surface. These sheets are designed to reflect light efficiently, making them ideal for various lighting applications. In lighting, reflective aluminum sheets are commonly used in fixtures and reflectors to direct and enhance the light output. The reflect ...

The representative alloy of 6063 has lower strength than 6061 and good extruding properties. It can be used as a profile with complex cross-sectional shapes, and has good corrosion resistance and surface treatment. Europium is a low-alloyed Al-Mg-Si series high-plasticity alloy. Has many valuable characteristics: 1. heat treatment strengthened, high impact toughness, not sensitive to lack. 2. Has excellent ...

3003 aluminum sheet and aluminum alloy sheet 5052 is the most common alloy aluminum plate on the market, Very widely used. In fact, there is a difference between them, for example aluminum sheet 3003 h24 with 5052 H24 aluminum sheet. From the scope of application, 3003 aluminum sheet is mainly used in wet environments, such as product packaging, refrigerators, air conditioning, cold storage, ventilation pipes ...

2024 T3 aluminum sheet has same characteristics as tubing, however, the sheet is alclad for corrosion resistance. Alclad is a metallurgically bonded aluminum or aluminum alloy coating that is anodic to the core, thus electrolytically protecting the core against corrosion. Tensile strength 70,000 psi, yield strength 50,000 psi. Anodized Aluminum sheet products and components are used in thousands of commercial, ...

Both 5005 aluminum and 6061 aluminum are aluminum alloys. They have a very high 99% of their average alloy composition in common. There are 31 material properties with values for both materials. Properties with values for just one material (1, in this case) are not shown. For each property being compared, the top bar is 5005 aluminum and the bottom bar is 6061 aluminum. Mechanical Properties ...

7075-T6 aluminum is 7075 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 7075-T6 aluminum to: 7000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the re ...

You may not know how to find out which aluminum sheet alloys are best.Aluminum sheet,also named as aluminum alloy sheet,is a oblong plate produced by aluminum stock. According to different alloy aluminum sheet metal elements, the aluminum sheet alloys can divided into 8 series mainly. Many friends want to find out which aluminum plate are best, but different series have different application scale with different ...