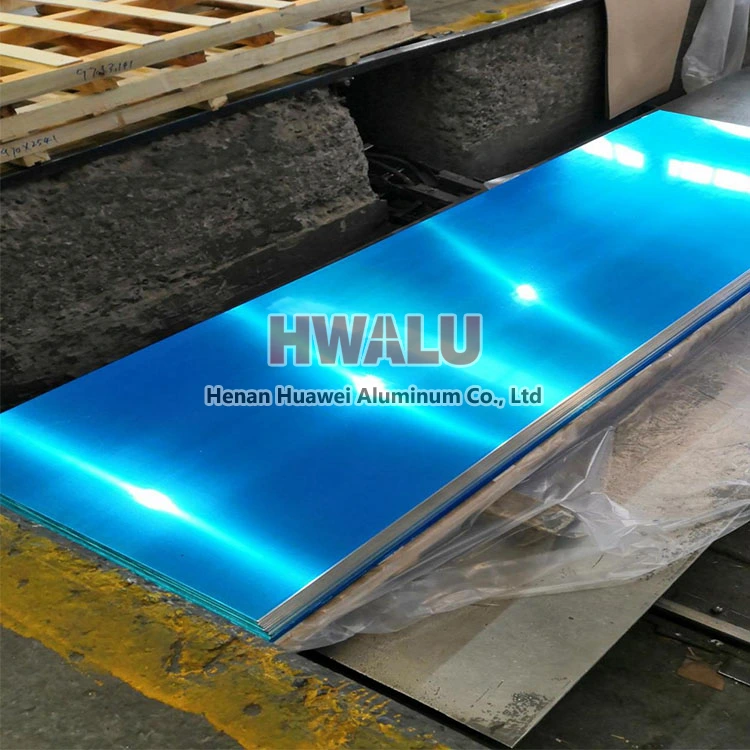

White aluminum plate product introduction White aluminum plate, also known as white aluminum plate, is a widely used material that is widely used in various industries. Aluminum sheet white has excellent strength, durability and corrosion resistance. This makes white aluminum sheet ideal for a wide range of applications, from construction and transportation to electronics and aerospace. White aluminum sheet ...

What thickness is a 20-gauge aluminum sheet? 20 gauge is one of the commonly used thin aluminum sheets, and the thickness of thin aluminum sheets ranges from 0.15-1.5mm. Gauge is a unit used to describe the thickness of aluminum plates, 20 gauge = 0.032 inches = 0.813mm. 20 ga, 22 ga, 24 ga which size is the thickest? As shown in the table below: The larger the Gauge Number, the smaller the corresponding in ...

Introduction of 5086 aluminum sheet 5086 alloy metal aluminum sheet plate - an aluminum alloy with the primary alloy element being magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material. Since heat treatment doesn't strongly affect the strength, 5086 can be readily welded and retain most of its mechanical strength. The go ...

Definition of 4mm aluminum sheets A 4mm aluminum sheet, also known as an aluminum plate, is a panel of aluminum that is 4 millimeters thick. It’s a result of basic raw-form aluminum being pressed and rolled into panel form under high pressure. Aluminum sheets are characteristically manufactured to be very thin and lightweight, yet sturdy enough to offer extreme versatility alongside inherent ease of installat ...

what is corrugated metal Corrugated metal refers to a type of sheet metal that is shaped into alternating ridges and grooves to increase its strength and stiffness. The ridges and grooves, known as corrugations, run the length of the metal sheet and are typically formed by rolling the metal through a series of dies. Corrugated aluminium sheet is often used for roofing and siding on industrial, commercial, and ...

5052-H32 Aluminum Sheet Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels 50 ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

Both 5005-H14 aluminum and 5005-H34 aluminum are variants of the same material. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing. For each property being compared, the top bar is 5005-H14 aluminum and the bottom bar is 5005-H34 aluminum. Mechanical Properties Brinell Hardness 48 43 E ...

The production technology of 6082 aluminum sheet.We offer 6082 aluminium alloy in bar, plate, tube and extrusions. 6082 belongs to the 6000 series (Al-Mg-Si) aluminum alloy sheet. It is a kind of aluminum alloy sheet which can be strengthened by heat treatment. It has medium strength, good weldability and corrosion resistance. It is mainly used in transportation and structural engineering industry. Such as bri ...

2024 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels 3003 aluminum sheet is a very cost effective grade, as it combines substantial strength and corrosi ...