What does the 4x10 aluminum sheet stand for? 4x10 aluminum sheet: A piece of aluminum is 10' long and 4' wide 10' is expressed in mm 10' = 3048 mm 4' is expressed in mm 4' = 1219.2 mm 4x10 aluminum sheet What are the usual sizes of aluminum plates? 4x10 aluminum sheet 4x8 aluminum sheet 5x10 aluminum sheet 6x10 aluminum sheet 6x12 aluminum sheet and so on 4x10 aluminum sheet Hot selling thick ...

what is 5005 aluminium sheet plate? 5005 alloy metal aluminium sheet plate belongs to 5000 series aluminum sheet . 5005 aluminium sheets can be cut to size at customers’ need. Mg is the principal element in the 5005 aluminium sheet and when it used as main alloying element or combined with Mn, high strength and no-heat treatable properties can be realized. 5005 aluminium sheet has many tempers available, such as ...

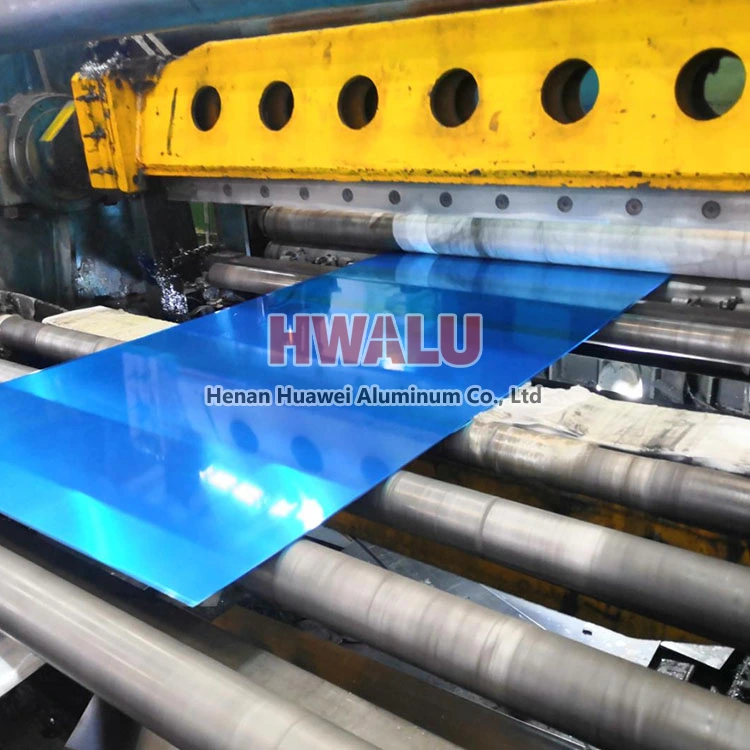

Aluminum alloys have strong corrosion resistance. They are sensitive to high temperatures ranging between 200 and 250°C (392 and 482°F) and might lose some of their strength. However, the strength of the aluminium alloys can be increased at subzero temperatures, making them ideal low-temperature alloys. We can produce many alloys by customer's requirements. It mainly includes 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, ...

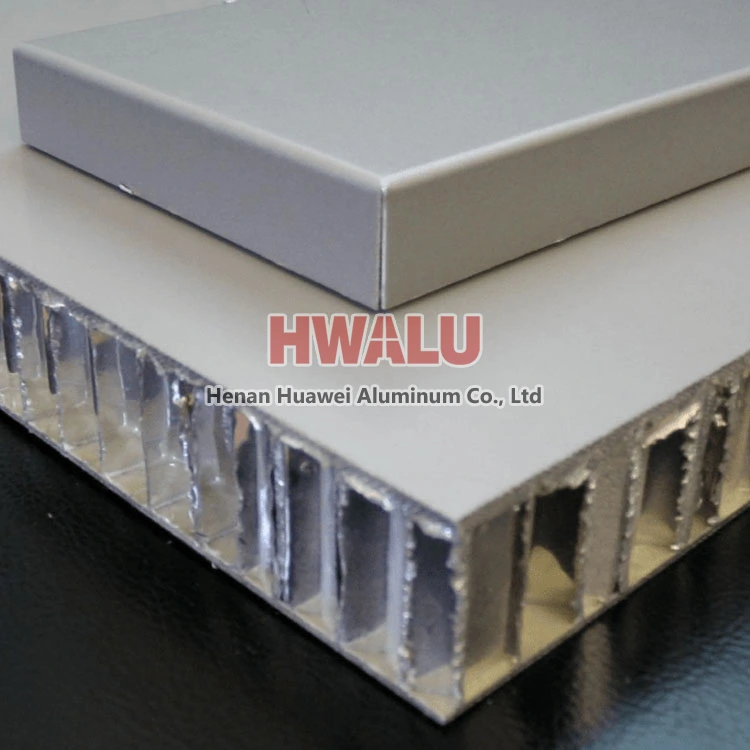

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

What is 1 8 aluminum checker plate Aluminum checker plate, also known as aluminum tread plate or aluminum diamond plate, is a type of metal sheet with a raised pattern of lines or diamonds on one side. The pattern provides increased traction and durability, making it ideal for use in industrial and commercial applications where slip resistance is important. 1 8 aluminum checker plate refers to a specific ...

1050 aluminum sheet belongs to industrial high purity aluminum alloy series, mainly used in some occasions requiring high corrosion resistance and formability, but the strength requirements are not high, chemical equipment is its typical use. Aluminium 1050 alloy is mainly used to produce all kinds of foils for electrolytic capacitors, acid-proof containers, etc. The products include aluminum sheet plate, tape ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

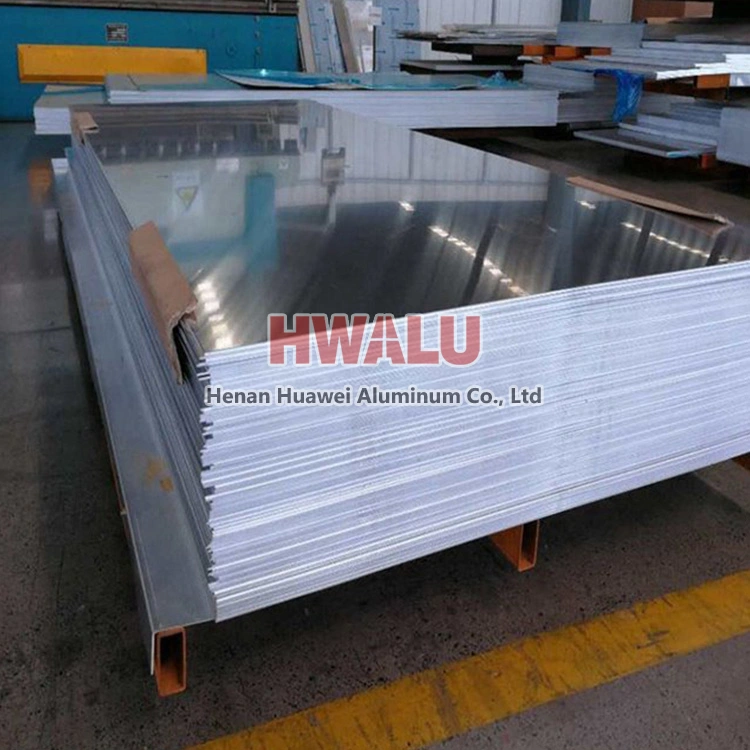

Aluminum sheet and aluminum plate are essentially the same; the only true distinction is in their respective thickness. Aluminum sheet is any aluminum sheet metal thicker than foil but thinner than 6mm; it comes in many forms including diamond plate, expanded, perforated and painted aluminum sheet. Aluminum plate is any aluminum sheet metal that is thicker than 6mm. Sheet, the most widely used form of aluminum ...

Grade 1050 aluminum sheet for making composite panel: An unalloyed non heat-treatable aluminium that is easily worked and has high resistance to corrosion and low strength.Aluminum sheet comes in 6061-T6 and 3003-H14 alloys. The 6061-T6 is the harder, more machinable aluminum sheet. The 3003-H14 is a softer, more formable aluminum sheet (when drilled and tapped, it is like chewing gum). Grade 5083 marine alumi ...

3004 aluminum sheet belongs to AL-Mn series alloys and are the most widely used rust-proof aluminum. 3004 aluminum sheet has good forming, welding and corrosion resistance, excellent shape processing characteristics, good conductivity, smooth surface, good plasticity and pressure resistance, higher strength than 3003 aluminum sheet. The thickness of aluminum sheet 3004 is 0.2-4.5mm, the width is 100-2600mm, th ...

How to calculate aluminum sheet price per ton per kg? The unit price of aluminum sheet, that is, "how much is aluminum sheet per ton or per kg", is one of the most concerned problems of every purchasing customer. In terms of technology, aluminum sheet refers to the rectangular sheet made by rolling aluminum ingot, which can be divided into pure aluminum sheet, alloy aluminum sheet, thin aluminum sheet, medium th ...