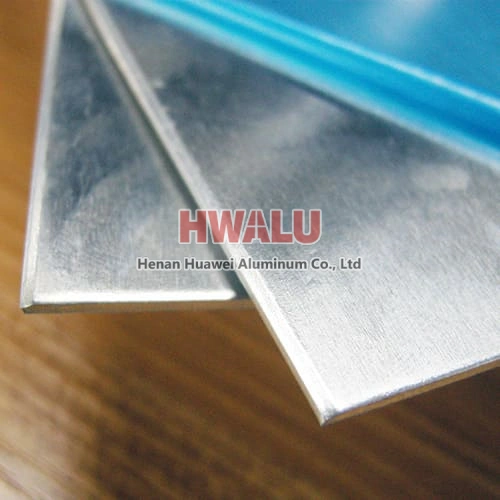

Thin aluminum sheet refers to aluminium sheets with thick between 0.15mm ~ 2mm. The parameters of 5052 thin aluminum plate as an example are for reference only. If you want to know more about the thin aluminum plate, please contact us as soon as possible. Alloy State Thickness Width Tensile strength (Mpa) Elongation (δ%)(Scaling distance 50) 5052 0 >0.5~1.3 >1.3~4.5 Above 500mm ...

What are the characteristics of 4017 aluminum plate? 4017 aluminum sheet plate has a variety of thicknesses and pattern sizes. 4017 aluminum alloy is a shiny surface similar to 3003. 4017 aluminum alloy provides durability. The constructed aging isotherm shows that EN 4017 with 0.19% Mg reaches a lower peak intensity than EN 4017 material with 0.43% Mg. The higher Mg variant of EN 4017 is comparable to the ag ...

What is Aluminum sheet plate for cover Aluminum sheet plates for cover are typically flat, rectangular pieces of aluminum that can be used in a variety of applications. They are often used in industrial settings, construction, furniture, appliances, and more. These plates are available in different alloys such as 1100, 2024, 3003, 5005, 5052, 5086, 6061, 6063, 7050, 7075, and others. They can be cut to size a ...

what is corrugated metal Corrugated metal refers to a type of sheet metal that is shaped into alternating ridges and grooves to increase its strength and stiffness. The ridges and grooves, known as corrugations, run the length of the metal sheet and are typically formed by rolling the metal through a series of dies. Corrugated aluminium sheet is often used for roofing and siding on industrial, commercial, and ...

What is "gauge" meaning for aluminuum sheet? In the context of aluminum sheets, “gauge” refers to the thickness of the sheet. It’s a standardized measurement system used to indicate the thickness of an aluminum sheet metal. There are two gauge systems used for aluminum sheets: American Wire Gauge (AWG): Ranges from 8 to 30, with the higher numbers indicating thinner sheets. Standard Wire Gauge (SWG): ...

5754-H22 aluminum is 5754 aluminum in the H22 temper. To achieve this temper, the metal is strain hardened, and then partially annealed, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H28). The graph bars on the material properties cards below compare 5754-H22 aluminum to: 5000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar m ...

5083 aluminum sheet is a high strength material, exhibiting higher strength than 5052 sheet.5083 H116 is an alloy used for high strength welded applications, with excellent marine environment corrosion resistance. It has a superior “skin finish” developed to prevent skin lamination, thus providing even better resistance to inter-granular corrosion than alloy 5083 H321. It has higher Tensile and Yield strengths th ...

Aluminum panels are now widely used in the construction industry, especially for decoration and building materials. Therefore, the beauty of the aluminum plate is more concerned. So now more manufacturers are more concerned about the aesthetics of the surface of the aluminum plate. 1. Electrophoresis painting This method of treatment is now the most used in Japan. After such treatment, the surface of the alumin ...

Color coated stucco aluminum sheet also called as color coated embossed aluminum sheet, the common seen embossed patterns on the surface are orange peel and rhombus/diamond pattern, the surface coating are fluorocarbon and polyester paint, the paint has various colors like white, black, red, green, blue, gray, yellow, gold and so on. The specification of color coated stucco embossed aluminum are: Alloys: 10 ...

Aluminum plates are widely used in engineering decoration, home decoration, communication electronics, transportation facilities, heat preservation and corrosion protection, fine decoration, automobile manufacturing and other fields. So, what are the knowledge points in the use of aluminum plates? Aluminum plate use Aluminum plate storage: It should be stored in a dry and ventilated place, and placed flat on ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels 3003 aluminum sheet is a very cost effective grade, as it combines substantial strength and corrosi ...