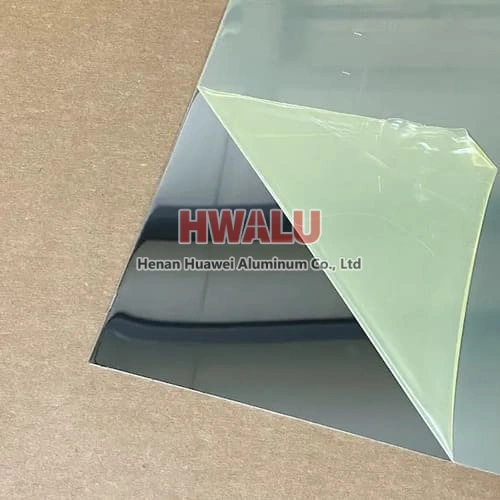

What is reflective aluminum sheet? What is aluminum sheet reflector? Reflective aluminum sheet, also known as mirror aluminum sheet or reflective aluminum, is a type of aluminum sheet. It has reflective surfaces that reflect light and heat. It has high reflectivity, also known as high reflective aluminum sheet. Reflective aluminum sheet refers to a thin and flat aluminum material that has been specially treated ...

what is 3105 aluminum sheet? 3105 aluminum plate belongs to a series of Al-Mn alloy, good rust resistance, good electrical conductivity, including 98% aluminum content, because the addition of 0.3% copper content, electrical conductivity is 41%; 3105 aluminum plate can not be heat treatment and reinforcement, so the use of cold treatment to improve its mechanical properties: annealing state plasticity is high, s ...

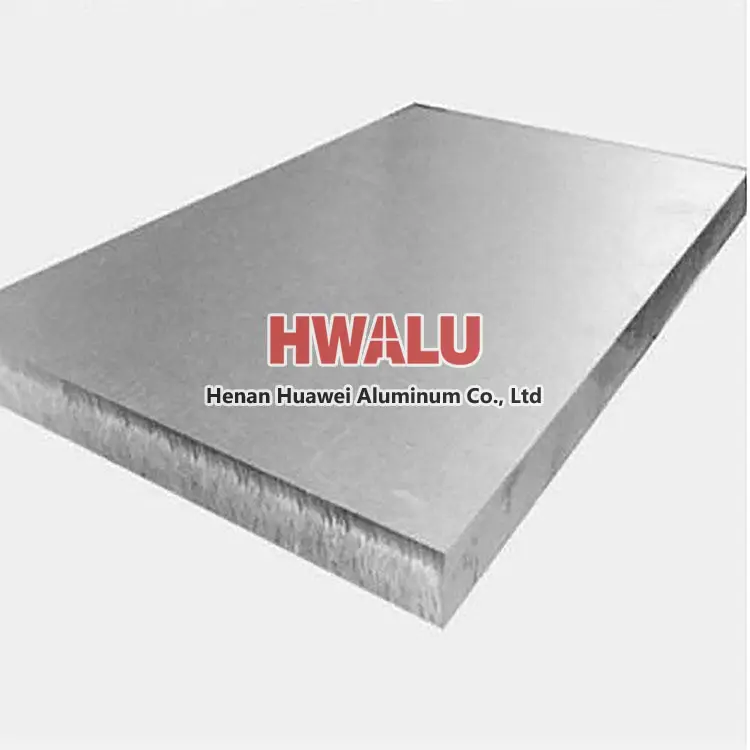

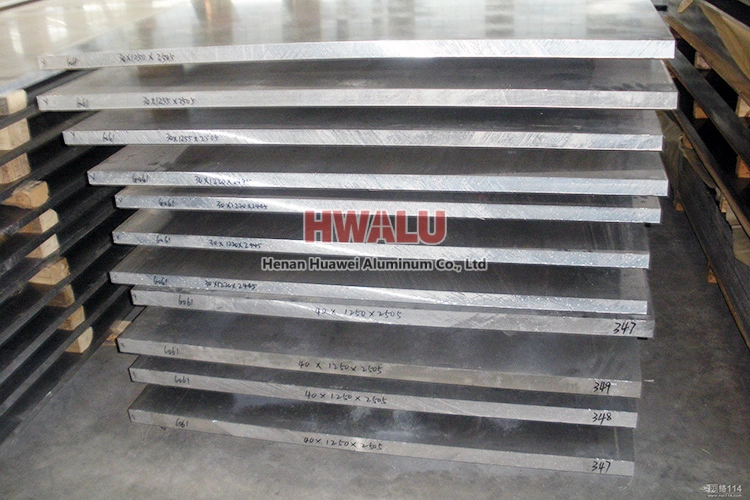

Super thickess aluminum plate refers to aluminium plates with thick between 200mm ~ 500mm. For example, the commonly used aluminum plate thicknesses are 200mm, 250mm etc

Aluminium Composite Panel (ACP) is a type of flat panel that consists of two thin aluminium sheets bonded to a non-aluminum core. ACP is used within the signage industry as an alternative to heavier, more expensive substrates. ACP is also used for external and internal architectural cladding or partitions, false ceilings, machine coverings, container construction, etc Composition and function As a new type ...

Welcome to Huawei Aluminum, your premier destination for high-quality '032 aluminum sheet' products. Our dedication to excellence in manufacturing and supplying aluminum sheets has made us a leading name in the industry. The '032 aluminum sheet' is versatile, durable, and widely used across various industries, including automotive, construction, aerospace, and more. About '032 Aluminum Sheet' The '032 aluminum ...

6061-t6 aluminum plate sheets available in stock.Aluminum plate sheets with excellent joining characteristics, good acceptance of applied coatings. Combines relatively high strength, good workability, and high resistance to corrosion; widely available. 6061-t6 aluminum sheet is one of the most common aluminum alloys for general use. It is a medium to high-strength alloy that can be heat treated, and it has exc ...

Aluminum sheet alloy 1050 is a common grade of 1000 series aluminum sheet plate, it belongs to pure aluminum plate sheet series. The mechanical properties of the 1050 aluminum sheet are not high, but because of the simple production process and mature technology, it has great advantages in price and high cost performance. Aluminum sheet 1050 is suitable for applied in industries that do not have strict require ...

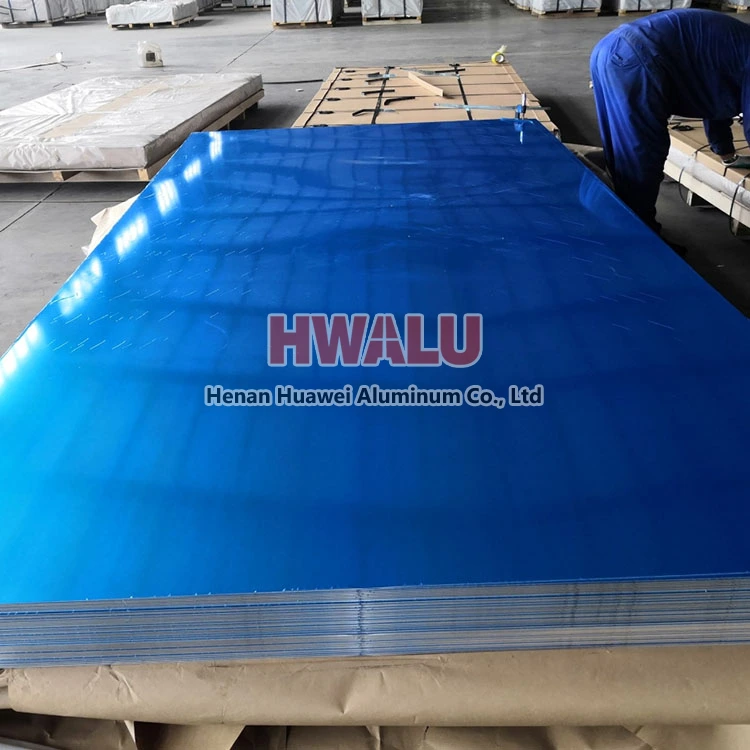

Hot rolling mill aluminum sheet generally refers to the rolling of metal above the crystallization temperature. Compared with ordinary cast-rolled products, hot-rolled aluminum sheet has good surface quality, while the mechanical properties as well as ductility are stronger and oxidation effect is good. Cold rolling aluminum sheet is also called cast aluminum sheet, cold rolling usually refers to the rolling o ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

3004 aluminium alloy sheet is the most widely used antirust AL-Mn aluminium alloy.The forming, solderability, corrosion resistance of 3004 aluminium sheet is good. For the processing of parts that require good formability, high corrosion resistance and good solderability, or require both these properties and require higher strength than 1XXX aluminum alloy work, such as kitchen utensils, food and chemical process ...

In terms of alloy composition, there are usually several kinds of rustproof aluminum plates: High purity rustproof aluminum plate (made by rolling high specular aluminum plate with 99.9 + content) Pure rustproof aluminum plate (the composition is basically rolled from mirror aluminum plate) Alloy rustproof aluminum plate (composed of aluminum and auxiliary alloys, usually aluminum-copper, aluminum-mangan ...