What is the cold rolling aluminium sheet? Cold rolling of aluminum sheets is usually carried out on a four-high or six-high mill. The cold rolling process of aluminum sheets is generally divided into rough rolling, intermediate rolling, and finishing rolling. Rough rolling and intermediate rolling focus on increasing pressure, strengthening the production process, and shortening the production cycle. The visc ...

Premier 2mm Aluminum Sheet Provider--huawei aluminum At Huawei Aluminum, we pride ourselves on being the leading provider of high-quality aluminum sheets, offering a diverse range of alloy models and specifications tailored to meet the needs of our global clientele. With state-of-the-art manufacturing facilities and a commitment to innovation and customer service, we ensure that every 2mm aluminum sheet we produ ...

Standard thickness aluminum sheet refers to aluminium sheets with thick between 2mm ~ 6mm. Hot sale thicknesses Unit ( mm ): 2mm, 2.4mm, 2.5mm, 2.6mm, 3mm, 3.2mm, 3.5mm, 4mm, 5mm, 6mm ( thick ) etc Unit ( guage ): 11, 10, 9, 8 ga etc Hot sale size 4x8 ( 2440 x 1220, 4x8ft ), 3mmx1mx1m etc Hot sale alloy temper 1100 ( a1100 ), 3003, 5052 H32, 5053 H38, 5086, 6061 T6, 7075 etc Application So ...

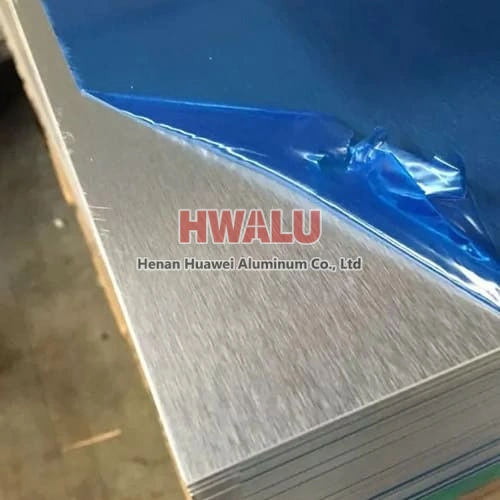

What is brushed aluminum sheets Brushed aluminum sheets are aluminum sheets that have a brushed finish applied to them. This finish is achieved by mechanically brushing the surface of the aluminum with a fine abrasive material. The brushing process creates a distinctive pattern of fine lines on the surface, giving the aluminum a stylish, modern look. Brushed aluminum sheets are commonly used in interior a ...

What is Mirror Aluminum Sheet Mirror Aluminum Sheet refers to an aluminum sheet coil with a mirror effect on the surface of the sheet, created by rolling, polishing, and other methods. The reflectivity of such sheets can reach more than 86%, and for high reflective mirror aluminum sheets, it can reach more than 95%. Common alloys for mirror aluminum sheet coil include 1000 series, 3000 series, and 5000 se ...

Before the aluminum alloy sheet is formed and completed, the surface of the plate needs to be pretreated to facilitate the processing of it later. Pretreatment includes 5 steps. Degreasing treatment: The purpose is to remove the lubricant and other dirt on the surface of the product, in order to ensure that in the alkali washing process, the surface corrosion of the product is uniform, in order to improv ...

6061 aluminum plate application for the mold making material.With aluminum sheet plate cost mold manufacturing indeed slightly higher, but the aluminum mold price is higher, because of its service life is far higher than other materials, and scrap aluminum can be recycled scrap value; compared to the previous aluminium die casting mould, it have a long life cycle, and does not appear to fall off. For example w ...

First of all, different alloy composition 6061 aluminum sheet plate and aluminum sheet plate 6063 is 6 series aluminum plate, 6 series aluminum plate is aluminum, magnesium, silicon alloy.7075 aluminum alloy elements for aluminum, zinc. 6061 aluminum plate and 6063 aluminum difference is small the silicon content of the former between 0.4 to 0.8, magnesium content between 0.8 to 1.2; 0.2 0.6, and 6063 silicon con ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

1. Current Situation of Aluminum Sheet in Automotive Field In the whole auto industry, the theme of energy conservation and environmental protection is becoming more and more popular, the application prospect ofAluminum Sheet in automotive fieldis generally seen to be positive.Aluminum Sheet in automotive field is light in weight and has the feature of wear resistance, good appearance, good formability, high s ...