what is a 5754 aluminum sheet? 5754 alloy metal aluminum sheet plate belongs to the 5000 series aluminum sheet, which is a typical alloy of Al-Mg elements ( almg3 ) with moderate strength, excellent processing performance, good corrosion resistance, weldability, and easy forming characteristics. 5754 aluminum sheets of different heat treatments are the main materials for manufacturing in the automotive industry ...

What is Aluminum sheet plate for cover Aluminum sheet plates for cover are typically flat, rectangular pieces of aluminum that can be used in a variety of applications. They are often used in industrial settings, construction, furniture, appliances, and more. These plates are available in different alloys such as 1100, 2024, 3003, 5005, 5052, 5086, 6061, 6063, 7050, 7075, and others. They can be cut to size a ...

What are the two types of aluminum anodizing? There are two main types of aluminum anodizing: sulfuric acid electrolytic oxidation and hard anodizing. Sulfuric acid electrolytic oxidation is a conventional anodic oxidation method, which uses sulfuric acid as the electrolyte to form an oxide film on the surface of aluminum by means of electricity. This oxide film has certain protective and decorative propertie ...

What is Mirror Aluminum Sheet Mirror Aluminum Sheet refers to an aluminum sheet coil with a mirror effect on the surface of the sheet, created by rolling, polishing, and other methods. The reflectivity of such sheets can reach more than 86%, and for high reflective mirror aluminum sheets, it can reach more than 95%. Common alloys for mirror aluminum sheet coil include 1000 series, 3000 series, and 5000 se ...

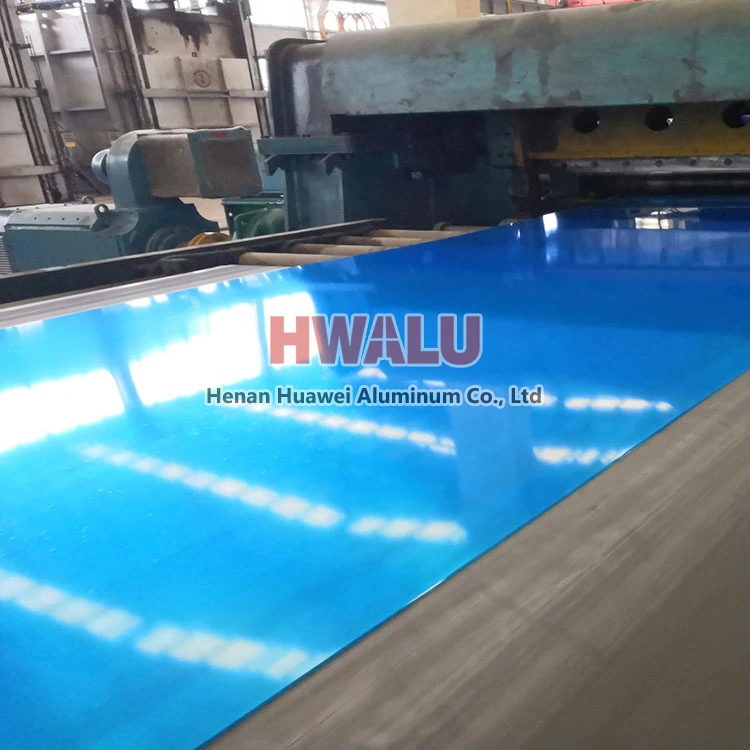

Aluminum sheet plate refers to aluminum material with width of 200mm over, and length of less 16000m. Custom Sizes 1 foot = 12 inch = 304.8 mm, 4 feet = 48 inches = 1220 mm Unit ( foot ): 4x4, 4x6, 4x8, 4x10, 4x12, 5x8, 6x8 etc Unit ( inch ): 12x12, 24x24, 24x36, 24x48, 36x36, 48x48 etc Hot sales sizes 4x8 foot aluminum sheet plate 5x8 ft ( 5 x 8 ), 60x96 inch ( 60 x 96 ), 1524 x 2438.4mm ...

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

3004 aluminum alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy ...

1050 aluminum is industrial aluminum with AI content of not less than 99.5%. The 1050 aluminum alloy has the characteristics of good electrical conductivity, good thermal conductivity and beautiful appearance. Stucco embossed aluminum plate can also be called aluminum embossed sheet, it belongs to the aluminum plate products after rolling and forming a variety of patterns on the surface, it is widely used in p ...

Aluminium sheet plate in aerospace applications.Aircraft-grade aluminium sheet plate are mainly used to produce aircraft fuselage, wing, tail wing and skins. These parts are usually directly milled using a high-strength aluminium plate to reduce manufacturing costs, reduce body weight and facilitate management. If the aluminium plates are not thick enough, these large parts cannot be cut at all. The thickest alum ...

First, the pure aluminum ingots are added to the aluminum alloy melting furnace to melt. These aluminum ingots that become blanks are removed from impurities such as dezincification, titanium and silicon. In this 25 tons of aluminum melting furnace, 24 tons of aluminum can be melted at a time, which requires 3 to For 8 hours, the furnace temperature is 750°C, and the melting point of aluminum is 660°C. During the ...

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manu ...

The 5052 h34 aluminum sheet is highly resistant to corrosion. It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments without worry of corrosion. This metal also has excellent thermal conductivity and low density, which is commonly found with other ...