Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

what is a 5754 aluminum sheet? 5754 alloy metal aluminum sheet plate belongs to the 5000 series aluminum sheet, which is a typical alloy of Al-Mg elements ( almg3 ) with moderate strength, excellent processing performance, good corrosion resistance, weldability, and easy forming characteristics. 5754 aluminum sheets of different heat treatments are the main materials for manufacturing in the automotive industry ...

What is 1 8 aluminum checker plate Aluminum checker plate, also known as aluminum tread plate or aluminum diamond plate, is a type of metal sheet with a raised pattern of lines or diamonds on one side. The pattern provides increased traction and durability, making it ideal for use in industrial and commercial applications where slip resistance is important. 1 8 aluminum checker plate refers to a specific ...

What is perforated aluminum sheet? Perforated aluminum sheet is punched on the aluminum plate with professional CNC equipment on a variety of perforated aluminum sheets, called perforated aluminum sheets After punching all kinds of holes through bending machine edge pressing, appearance to do fluorocarbon, or powder spraying, do not let the aluminum plate natural oxidation, or for beauty, do a variety of favori ...

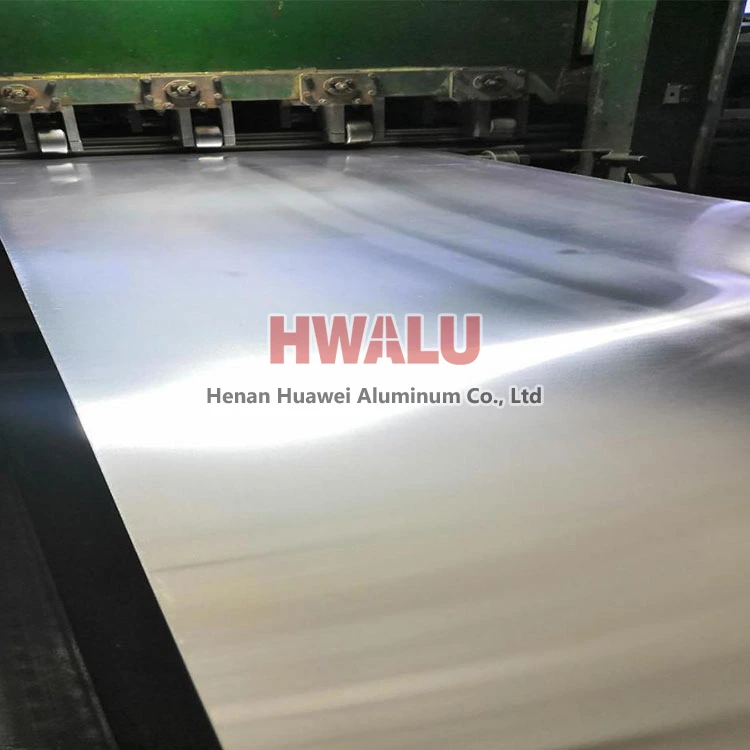

What is the cold rolling aluminium sheet? Cold rolling of aluminum sheets is usually carried out on a four-high or six-high mill. The cold rolling process of aluminum sheets is generally divided into rough rolling, intermediate rolling, and finishing rolling. Rough rolling and intermediate rolling focus on increasing pressure, strengthening the production process, and shortening the production cycle. The visc ...

1060 aluminum sheet is another representative product in 1000 series aluminum alloys. 1060 aluminum alloy is formed by pure aluminum added by a small amount of copper element, which has excellent forming processing characteristics, high corrosion resistance, good weld ability and conductivity. The same as 1050 aluminum sheet, the aluminum sheet 1060 is widely used in products with low strength requirements, such ...

6061 aluminum plate application for the mold making material.With aluminum sheet plate cost mold manufacturing indeed slightly higher, but the aluminum mold price is higher, because of its service life is far higher than other materials, and scrap aluminum can be recycled scrap value; compared to the previous aluminium die casting mould, it have a long life cycle, and does not appear to fall off. For example w ...

5754 aluminum sheet and 5052 aluminum sheet are all 5000 series anti-rust aluminum alloy. This Al- Mg alloy is with medium strength, especially with anti fatigue strength, high plasticity and corrosion resistance, no can be heat treatment, good weld-ability, and can be polished. 5052 and 5754 aluminium sheet is mainly used for low load parts that require high plasticity and good weldability, working in liquid ...

Aluminum Alloy 6061 sheets are the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2000 and 7000 alloys, 6061 aluminum provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the ""O"" temper or annealed condition, alloy 6061 has good formability. In the T4 condition, fairly severe form ...

Aluminum alloy 3105 is essentially a 98% aluminum alloy with minor additions to increase strength over that of alloy 1100 and 3003. It is not hardenable by heat treatment and it has good corrosion resistance, formability and weldability. Typical applications include general sheet metal work requiring greater strength than is provided by 1000 series aluminum alloys, residential siding, mobile homes and sign making ...

Have you ever encountered a manager who customized the project, the thickness of the aluminum plate did not meet the standard, and the thickness was routine? For conventional aluminum squares, the thickness of the aluminum gusset varies from 0.6 to 1.2 mm, while the thickness of the conventional aluminum veneer is 1.5, 2.0, 2.5, and 3.0 mm. According to the national industry standard, the standard floor use ...