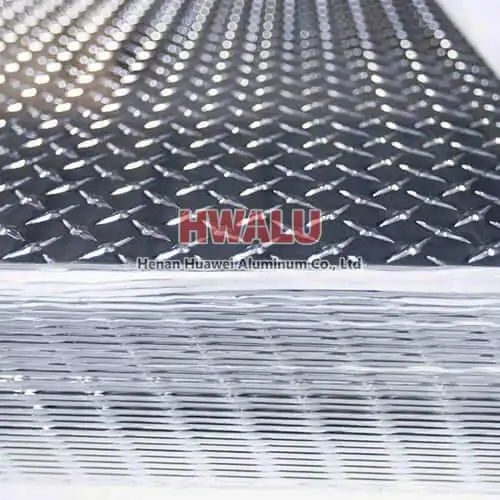

What is diamond aluminum sheet? Diamond aluminum plate, also known as diamond plate or diamond pattern plate, is an aluminum plate with a raised diamond pattern on one side. The diamond-shaped aluminum plate pattern provides increased traction and durability, making it ideal for applications where slip resistance is important, such as industrial floors, stairs, ramps and truck beds. Aluminum diamond sheet c ...

Standard thickness aluminum sheet refers to aluminium sheets with thick between 2mm ~ 6mm. Hot sale thicknesses Unit ( mm ): 2mm, 2.4mm, 2.5mm, 2.6mm, 3mm, 3.2mm, 3.5mm, 4mm, 5mm, 6mm ( thick ) etc Unit ( guage ): 11, 10, 9, 8 ga etc Hot sale size 4x8 ( 2440 x 1220, 4x8ft ), 3mmx1mx1m etc Hot sale alloy temper 1100 ( a1100 ), 3003, 5052 H32, 5053 H38, 5086, 6061 T6, 7075 etc Application So ...

What is Aluminium Anti-slip Plate Aluminum anti-slip plate, also known as aluminum tread plate or aluminum checker plate, is a type of aluminum sheet with a raised pattern on one side to provide enhanced slip resistance. This pattern, often in the form of diamonds or bars, helps to reduce the risk of slipping and improves safety in various applications. Aluminum anti-slip plates are commonly used in industria ...

what is 1/16" 5052-H32 Aluminum Plate? 1/16" 5052 H-32 Aluminum - Aluminum alloy containing magnesium is stronger than series 3003 aluminum. This grade has excellent corrosion resistance and the best welding characteristics of all aluminum. Applications include truck and trailer parts, aircraft parts, hulls, ladders, railings, toolboxes, kitchen equipment, trim pieces, sign billets, and any other application ...

Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

Aluminium Alloy 2024 T4 Sheets are widely used for a majority of the reasons. Its cheap, light-weight, and high performance are the main reasons for its widespread use. It is chemically resistive, non-sparking, electrically conductive, reflective, thermally conductive, non-magnetic. It is implemented in the marine and aerospace industries, construction, electronic enclosures, aircraft, and spacecraft. Aluminiu ...

The outstanding chemical property of 3003 aluminum sheet is about the corrosion resistance, while the physical property is about the high strength. Because 3003 aluminum alloy has high strength and corrosion resistance, it is widely used in the field of aluminum tread plate, packaging foil, container foil and aluminum-plastic composite board. At present, the production of 3003 aluminum sheet plate generally ad ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

The 7075 aluminum sheet is a product that is frequently used because of its strength, toughness and corrosion resistance. It is in fact one of the strongest aluminum alloys out there. Its weight-to-strength allows it to be used for high stressed parts. In the annealed condition, the 7075 aluminum can be formed using heat methods. It’s not good with cold working. Once formed, it’s recommended that heat treatment b ...

Generally speaking, the surface of 1100 aluminum sheet and 1060 aluminum sheet plate looks very smooth, and it is difficult to distinguish the quality. We can judge it from four aspects. First,is the composition of 1100 or 1060 aluminum plates pure aluminum?Aluminum content greater than 99% is called pure aluminum, 1100 aluminum content is 99%, and 1060 aluminum content is 99.6%. Other ingredients are iron and ...

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manu ...