What is the cold rolling aluminium sheet? Cold rolling of aluminum sheets is usually carried out on a four-high or six-high mill. The cold rolling process of aluminum sheets is generally divided into rough rolling, intermediate rolling, and finishing rolling. Rough rolling and intermediate rolling focus on increasing pressure, strengthening the production process, and shortening the production cycle. The visc ...

Aluminum sheet plate refers to aluminum material with a thickness of 0.2mm over to less 500mm. Classification by thickness Thin aluminum sheet plate Standard thickness aluminum sheet plate Medium thickness aluminum plate Thick aluminum sheet plate Super thick aluminum sheet plate Different thickness aluminum sheet determines its different functions. And different functions can be used in diff ...

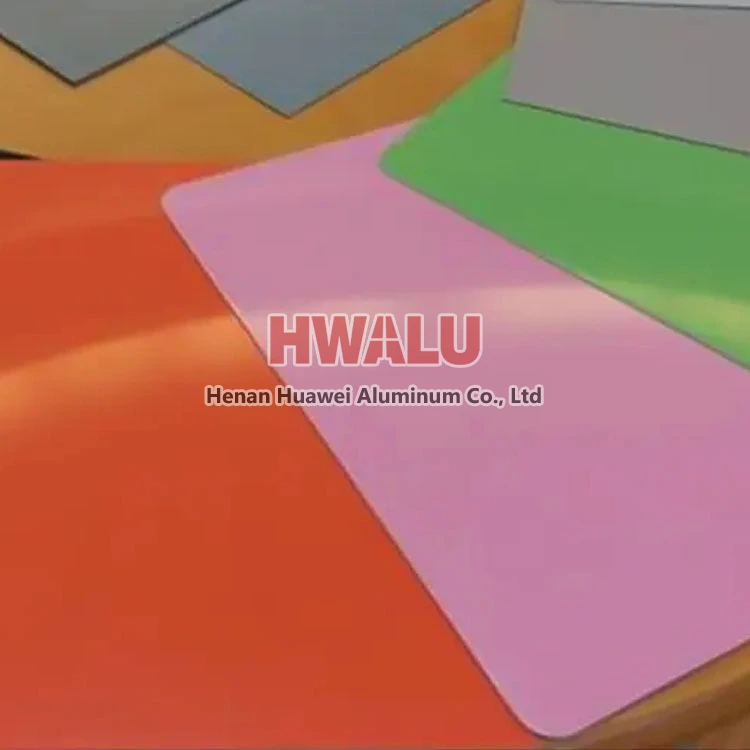

What is color coated aluminum sheet Color coated aluminum sheet is a kind of aluminum plate with a coated surface, usually by applying one or more layers of organic paint on the surface of the aluminium plate, and then curing it by heating it to form a layer of wear-resistant, anti-corrosion, and anti-ultraviolet color coating. layer. This aluminum plate not only has excellent corrosion resistance and wear re ...

What is 050 aluminum sheet The 050 aluminum sheet refers to an aluminum sheet with a thickness of 0.05 inches, which is equivalent to 1.27 millimeters. It’s a common material used in various industrial manufacturing and household applications due to its strength, light weight, and corrosion resistance. Specifications for the 050 aluminum sheet Alloy Types: 1000, 3000, 5000, 6000 series Temper: O, H12, ...

White aluminum plate product introduction White aluminum plate, also known as white aluminum plate, is a widely used material that is widely used in various industries. Aluminum sheet white has excellent strength, durability and corrosion resistance. This makes white aluminum sheet ideal for a wide range of applications, from construction and transportation to electronics and aerospace. White aluminum sheet ...

Aluminum sheets Main products include 1-8 series aluminum plate/strip/coil/foil. We also produce mirror aluminum sheet, aluminum checkered plate, tread plate, embossed aluminum plate,etc a.Light weight b.Low cost c.Easier and convenient to install d.Environmental friendly and energy saving e.Anti-dirt and self-cleaning f.Corrosion resistant and moisture proof g.Weathering resistance strong ...

5005 aluminum alloy is an aluminium alloy with good resistance to atmospheric corrosion. It is used in decorative and architectural applications. It is a member of the 5000 series of aluminum-magnesium wrought alloys. As such, it is not used in casting. It can attain moderate to high strength by cold working, and has relatively high welded strength, workability, and corrosion resistance compared to other aluminum ...

Do you know 6082 aluminum sheet introduction and development? 6082 aluminum sheet contains Mn as the alloy element, and Mn is refractory metal. Therefore the 6082 aluminum plate has good quality, oxidation resistant, beautiful surface, durable, durable, resistant to impact and wear, the material looks very good, very thick and very strong. The main temper of 6082 aluminum sheet are O, T4, T6 and T651, the thic ...

2024 T3 aluminum sheet has same characteristics as tubing, however, the sheet is alclad for corrosion resistance. Alclad is a metallurgically bonded aluminum or aluminum alloy coating that is anodic to the core, thus electrolytically protecting the core against corrosion. Tensile strength 70,000 psi, yield strength 50,000 psi. 5083 aluminum sheet application: Due to its strength and temperature characteristics ...

1. One of the factor: emulsion concentration (C)The influence of the emulsion concentration on the rolling surface is realized by the thickness of the oil film formed in the deformation zone. The concentration is too low and the oil equivalent precipitated in the deformation zone is low. The thickness of the oil film forming the minimum fluid lubrication must be 3 times the combined surface roughness. High concen ...

For high-grade metal processing enterprises and chassis enterprises, 5052 aluminum is the most commonly used materials in the large amount of chassis and other high-end products, we suggest that in the application of 5052 aluminum sheet , H32 suitable for sheet metal bending process, the application case of more mature production technology. 5052 aluminum sheet as a high-grade alloy products with excellent perfo ...

Aluminum 6061 T4 Sheet is solution heat treated and naturally aged giving it slightly lower tolerance accuracy than Aluminum 6061 T6, which undergoes artificial aging. T4 is also slightly less expensive than T6 and has a slightly lower ultimate tensile strength and yield strength, with a higher elongation percentage, which increases the formability of the T4 temper. Aluminum sheet 6061 T4 is also cost friendlier ...