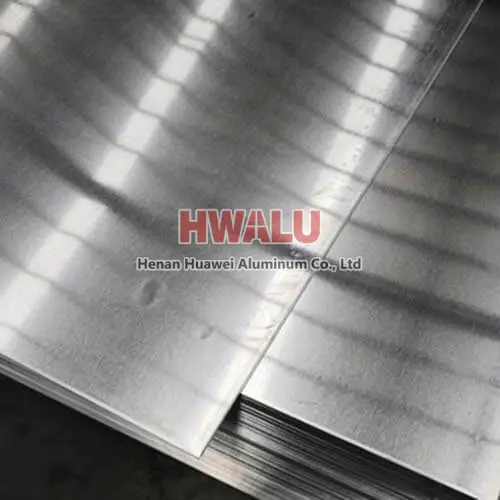

What is .125 Aluminum Sheet? .125 aluminum sheet is a versatile and widely used material in various industries. It is made of aluminum alloy, which is known for its lightweight, strength, and corrosion resistance. The "125" in the product name refers to the thickness of the sheet, which is 0.125 inches. Factory--Huasheng Aluminum As a leading manufacturer of aluminum sheets, Huasheng Aluminum offers a comp ...

what is 3xxx series aluminum sheets? 3xxx series aluminum sheets can be called anti-rust aluminum sheets. It is mainly composed of manganese. The content is between 1.0-1.5. The production process of our 3 series aluminum sheet is more sophisticated. 3 series aluminum plate is a series with better anti-rust function, which is often used in humid environments such as air conditioners, refrigerators, and car ...

4x8 aluminum checker plate product The 4x8 aluminum checker plate is a popular type of metal plate that features a raised pattern on the surface of the aluminum plate. Aluminum pattern plates not only retain the excellent characteristics of ordinary aluminum alloy materials, such as excellent corrosion resistance and weather resistance, but also have some special properties, such as anti-skid, wear-resistant, an ...

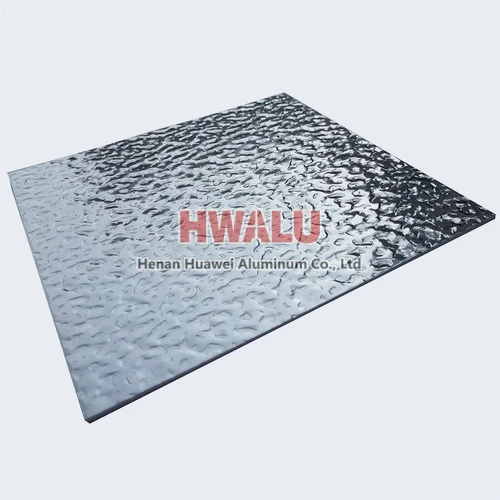

What is embossed aluminum sheet plate? What is embossed aluminum? Embossed aluminum plate, also known as aluminum embossed plate, is an aluminum product that is formed on the surface with various patterns on the surface through rolling processing based on the aluminum plate. Embossed aluminum sheet not only has the basic characteristics of aluminum sheets, such as light weight, corrosion resistance, easy process ...

what is Aluminum corrugated sheet? Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold- ...

The density of pure aluminum is small, about 1/3 that of iron. The density of aluminum alloy naturally varies according to the model and the alloying elements added, and the density of aluminum sheet ranges from 2.7 to 2.84. The densities of several commonly used aluminum alloy plates are as follows. 1 series aluminum plate density: 0.00271 kg/m³ 2xxx series aluminum sheet density: 0.0028 kg/m³ 3000 s ...

Both 5052 aluminum and 6061 aluminum alloys can undergo the anodizing process to increase corrosion resistance and enable dying (coloring). The anodic layer is non-conductive.But 6061-T6 aluminum sheet is the most commonly used aluminum alloys. The main alloy ingredients are magnesium and silicon. Common uses for this alloy are in the manufacturing of fishing reels, truck frames, structural components, machine ...

Aluminum 6061 sheet is a heat-treated and strengthenable alloy, produced by heat-treatment pre-drawing process for high quality aluminum alloy products. Advantages and disadvantages of 6061 aluminum alloy. Although the strength of 6061 cannot be compared with 2-series or 7-series, its magnesium and silicon alloy has many characteristics, and has good processing performance, excellent welding characteris ...

Deep processing mode: 1. Surface treatment: pickling, alkali washing, organic liquid cleaning, polishing, polishing, sandblasting, electroplating, anodic oxidation, electrolytic coloring, coating (roll coating, spraying), printing, embossing, drawing, etching; 2. Hardware stamping class: punching, flanging, flanging, curling, bending, stamping, expanding, spinning, flaring, shrinking, rolling, drawing, thin ...

Like all the 5000-series high magnesium alloys 5083 achieves a high strength by cold working, enabling a series of “H” tempers; 5083 aluminium alloy sheet plate is the highest strength of any of these alloys.Alloy 5083 is best known as a plate for ship building.Alloy 5083 is a non-heat-treatable 4?% magnesium, 0.15% chromium, 0.7% manganese alloy commonly available in flat rolled plate from a range of producing m ...

2024 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. ...