What is the size of 0.187 inch aluminum sheet? 0.187 is the thickness of the aluminum plate, representing 0.187 inches thick. Aluminum sheet thickness 0.187 is a common thickness found in industries such as construction, manufacturing, automotive, aerospace, and craft. 0.187 inch aluminum sheet thickness 0.187-inch aluminum sheet refers to an aluminum sheet with a thickness of 0.187 inches (or about 3/16 i ...

what is 1/16" 5052-H32 Aluminum Plate? 1/16" 5052 H-32 Aluminum - Aluminum alloy containing magnesium is stronger than series 3003 aluminum. This grade has excellent corrosion resistance and the best welding characteristics of all aluminum. Applications include truck and trailer parts, aircraft parts, hulls, ladders, railings, toolboxes, kitchen equipment, trim pieces, sign billets, and any other application ...

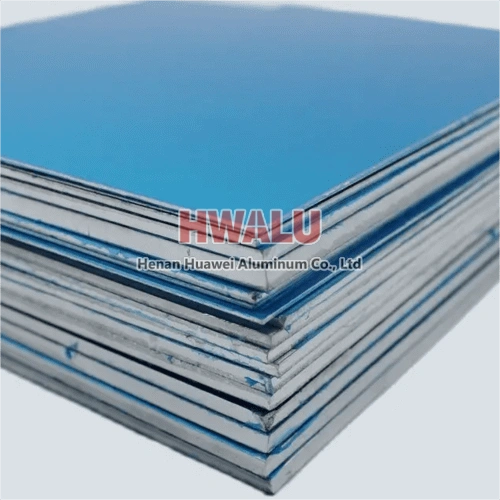

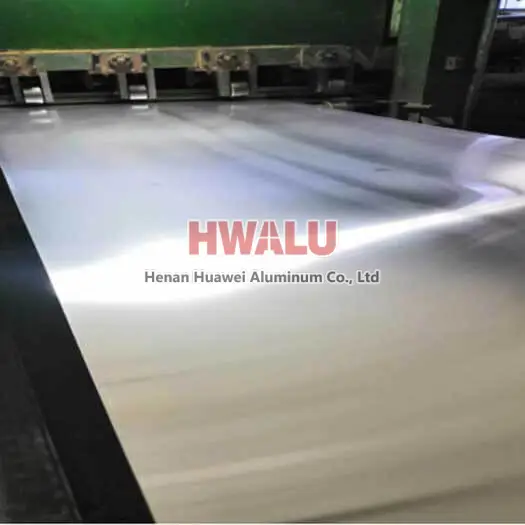

1mm aluminum sheet product Aluminum sheet is a lightweight, corrosion-resistant, recyclable material. Due to its good electrical and thermal conductivity, it is widely used in construction, aviation, automobiles, packaging and other fields. Aluminum plates are also easy to process, easy to shape, and easy to cut. 1mm aluminum sheet weight per square meter An aluminum plate with a thickness of one millimete ...

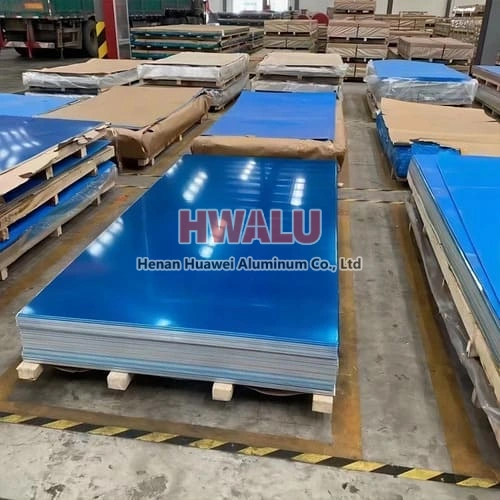

Premier 0.8mm Aluminum Sheet Factory and Wholesaler Introduction Welcome to Huawei Aluminum, your trusted source for high-quality 0.8mm aluminum sheets. Our precision-engineered sheets are crafted to meet the diverse needs of various industries, offering durability, versatility, and performance. Product Overview Our 0.8mm aluminum sheets come in a range of alloy models, each tailored for specific applic ...

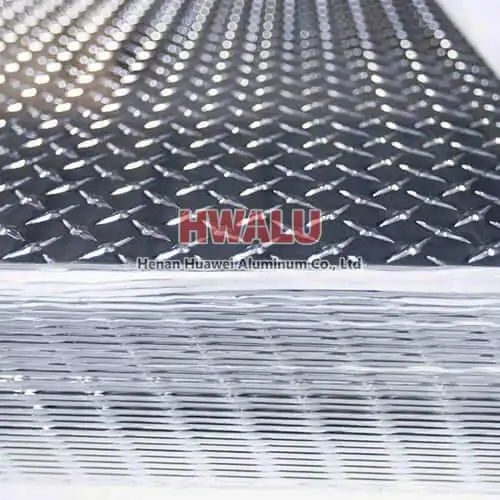

What is Aluminium Anti-slip Plate Aluminum anti-slip plate, also known as aluminum tread plate or aluminum checker plate, is a type of aluminum sheet with a raised pattern on one side to provide enhanced slip resistance. This pattern, often in the form of diamonds or bars, helps to reduce the risk of slipping and improves safety in various applications. Aluminum anti-slip plates are commonly used in industria ...

6063 Aluminum sheet is widely used in frame construction aluminum doors and windows, curtain walls, in order to ensure the high wind resistance performance, assembly performance, corrosion resistance and decorative properties, the comprehensive performance requirements of the Aluminum Alloy is much higher than the industrial standard. 6063 alloy has lower strength than 6061 alloy, it is with good extrusion, corro ...

Look at the color: Anodized aluminum products usually come in different colors, which can range from light white to dark black. This is due to the difference in the thickness of the alumina film and the composition of the electrolyte. Generally speaking, the thicker the aluminum oxide film is, the darker it is. Check the surface texture: The surface of anodized aluminum products is usually rough, with obvi ...

3004 aluminum sheet belongs to AL-Mn series alloys and are the most widely used rust-proof aluminum. 3004 aluminum sheet has good forming, welding and corrosion resistance, excellent shape processing characteristics, good conductivity, smooth surface, good plasticity and pressure resistance, higher strength than 3003 aluminum sheet. The thickness of aluminum sheet 3004 is 0.2-4.5mm, the width is 100-2600mm, th ...

5005 h34 aluminum sheet commonly used in the manufacture of appliances, small boats, gas lines, refrigerator panels, and utensils. 5005 is also used in architectural components, and as an electrical conductor. Especially useful where excessive finishing costs are encountered in the use of 3003 alloys due to surface roughness upon drawing. the 5052 aluminum alloy is used to make beverage closure without interna ...

The 5005 aluminum sheet price on the market is affected by the specification and usage. As one alloy in 5000 series aluminum, 5005 aluminum is not as famous as 5052, 5083 and 5086 aluminum. But 5005 aluminum sheet also have many application in the industry, it is used as conductor, cookware, instrument panel, lighting, instrument case and architectural decoration, high-end curtain wall board, etc.The 5005 alum ...