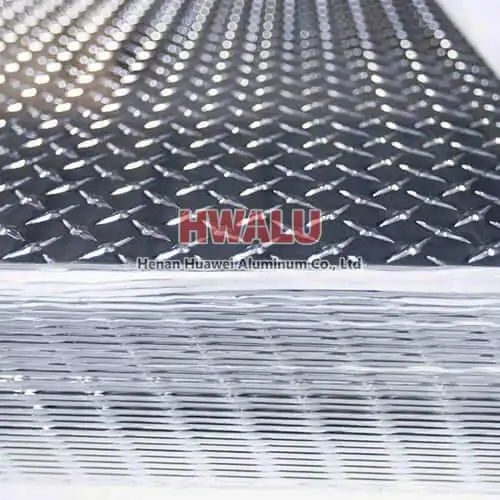

What is Aluminium Anti-slip Plate Aluminum anti-slip plate, also known as aluminum tread plate or aluminum checker plate, is a type of aluminum sheet with a raised pattern on one side to provide enhanced slip resistance. This pattern, often in the form of diamonds or bars, helps to reduce the risk of slipping and improves safety in various applications. Aluminum anti-slip plates are commonly used in industria ...

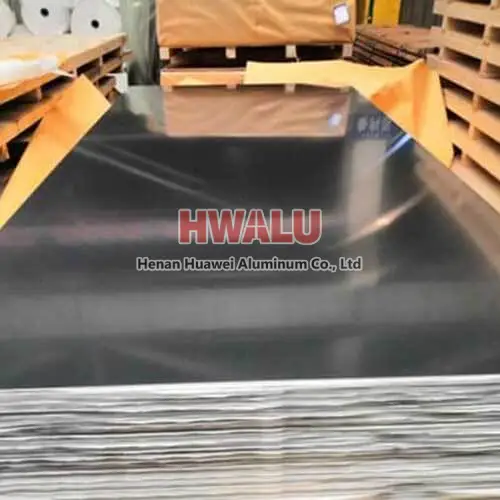

What is 5052 aluminum sheet/plate? 5052 alloy metal aluminum sheet plate belongs to 5000 series aluminum sheet, which is highly resistant to corrosion. It belongs It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium, and it belongs to 5 series. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments ...

Introduction The thickness of a 1 16 aluminum sheet is exactly that—1/16 of an inch. In decimal terms, this is equivalent to 0.0625 inches. In millimeters, it translates to approximately 1.59 mm. It’s a commonly used thickness for a variety of applications due to its balance of flexibility and strength. The 1 16 aluminum sheet is a popular material choice across industries due to its versatility, durability, ...

What is 4x8 diamond plate aluminum sheets A 4x8 diamond plate aluminum sheet is a standard-sized sheet of aluminum that has been embossed with a diamond pattern. The dimensions of the sheet are 4 feet by 8 feet. Advantages of using 4x8 diamond plate aluminum sheets 4x8 diamond plate aluminum sheets have several advantages that make them a popular choice for various applications: 1. Skid-resistance: Th ...

aluminum 6061-t651 material properties 0.75" 6061-T651 is the main alloy of 6061 alloys. It is a high-quality aluminum alloy product produced by heat treatment and pre-drawing process. Although its strength cannot be compared with the 2XXX series or 7XXX series, it has many magnesium and silicon alloy characteristics, such as excellent machining performance, excellent welding characteristics, electroplating, goo ...

Brinell hardness test method: This is a commonly used metal hardness test method, which is applicable to various metals and alloys. This method uses a steel ball or drill bit with standard geometric shape and size, presses a certain load on the aluminum plate to be tested, and determines the hardness value according to the indentation depth. The hardness value of aluminum plate is usually expressed in Brinell ...

5083-H32 aluminum is 5083 aluminum in the H32 temper. To achieve this temper, the metal is strain hardened, and then stabilized, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H38). The graph bars on the material properties cards below compare 5083-H32 aluminum to: 5000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means thi ...

Earlier in the time, people used to obtain aluminium through welding. At the primary level, rubbing or welding of aluminium was a tough nut to crack. To begin with, it was made to keep in a hollow and big bombshell. The tension and contact pressure were created simultaneously. The tractable strength of joints was estimated after it. As per the examinations performed aluminium welding impacted welding boundaries o ...

1. Changeable shape and amazing light transmission: aluminum perforated sheets are not only lighter than conventional aluminum plates with the same area, but also have more decorative effects. The perforated aluminum panel has various shapes and strong plasticity. On the one hand, it can be processed into arcs, hyperbola, special shapes, and other shapes. On the other hand, it can be carved or stamped out in vari ...

Both 1100-H14 aluminum and 1100-H24 aluminum are variants of the same material. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing. There are 31 material properties with values for both materials. Among the tempers from O to H32, the most common temper of the 1100 aluminum sheet is h14, we called it aluminum sheet 1100 h14. ...

The application of Aluminium in construction and architecture slowed in the 1940s, as the metal was predominantly used for producing planes. It even earned a second name, "winged metal." But as early as the middle of the twentieth century, Aluminium sheet became more and more popular in the construction of high-rise buildings and bridges. Window frames, panels, domed roofs and other wide-span constructions and or ...