Parameters of aluminum sheet plate for license plate Alloys: 1050, 1060, 6061 etc Temper: HO, H14, T6 etc Sizes: 6" 12" ( 12'' x 6'', 6x12 inch ), 10x5 ( 5"x10" ) etc Surface treatment: Anodized, color coated etc Application Aluminum plain license plates can be used in many places for stamped street traffic signs, laser cutting house door number sign, CNC embossing number metal aluminum logo automot ...

Ⅰ: Aluminium sheet price list Date:Based on April 1st,2022-March 28th ,2022 LME Weekly Average Price 3545 USD No. "Thickness mm" "Width*Length feet/mm" "MOQ ton" " FOB usd/ton" 1 0.2-0.29 3.27'*6.55'(1000*2000mm) 6.00 3805.00 3.93'*7.86(1200*2400mm) 8.00 4'*8'(1220*2440mm) 8.00 4.09'*8.19'(1250*2500mm) 8.00 4.91'*9.83'(1500*3000mm) 10.00 2 0.3-0.39 Same As A ...

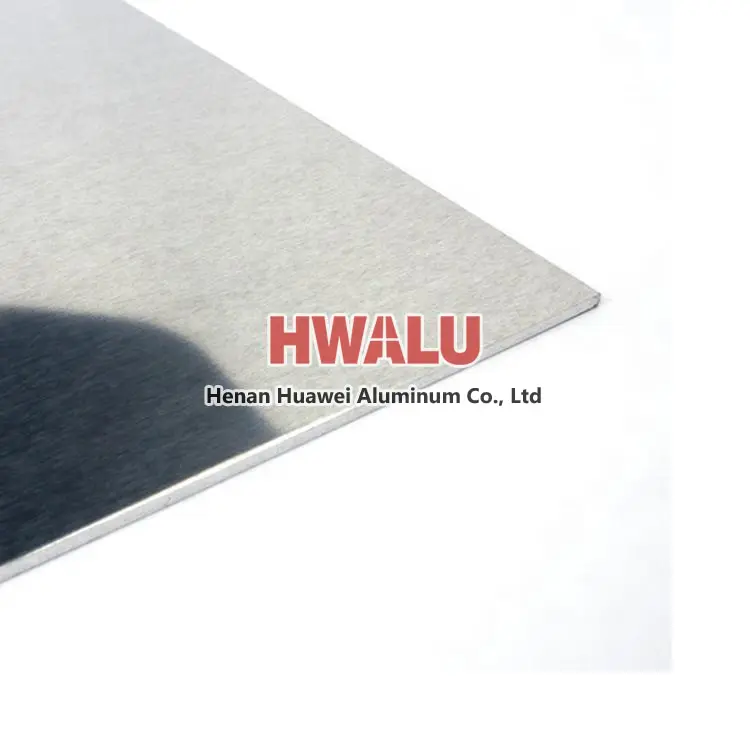

Aluminum sheet plate refers to aluminum material with a thickness of 0.2mm over to less 500mm. Classification by thickness Thin aluminum sheet plate Standard thickness aluminum sheet plate Medium thickness aluminum plate Thick aluminum sheet plate Super thick aluminum sheet plate Different thickness aluminum sheet determines its different functions. And different functions can be used in diff ...

Specifications of Aluminum Sheet for ceiling Grade 1 xxx,2xxx,3xxx,4xxx,5xxx,6xxx,7xxx,8xxx,9xxx Thickness 0.2mm - 350mm Width 5mm - 2500mm Temper all available Common sizes: 2x2 ft, 60 x 60 cm, 300*300mm etc Features of aluminum sheet plate for ceiling Aluminum plate features: Good heat insulation effect: high thermal reflectivity, reducing indoor temperature by 8-10 degre ...

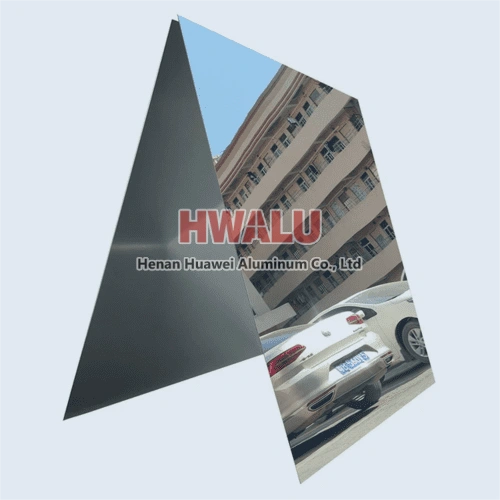

What is reflective aluminum sheet? Reflective aluminum plate is a type of aluminum plate with a reflective surface that can reflect light and heat. Its surface is polished or coated to form a special structure with reflective function. When light irradiates the surface of the aluminum plate, reflection occurs. Because aluminum has good electrical conductivity, it can quickly conduct the light to the inside of th ...

The production technology of 6082 aluminum sheet.We offer 6082 aluminium alloy in bar, plate, tube and extrusions. 6082 belongs to the 6000 series (Al-Mg-Si) aluminum alloy sheet. It is a kind of aluminum alloy sheet which can be strengthened by heat treatment. It has medium strength, good weldability and corrosion resistance. It is mainly used in transportation and structural engineering industry. Such as bri ...

The applications of automotive aluminum sheet increased significantly The latest research shows that the future demand for aluminum sheets will grow at an unprecedented rate. 2014 and 2015 are considered a turning point in the automotive industry from traditional steel to aluminum and other lightweight materials, including the use of aluminum instead of advanced high strength steel (AHSS). I ...

Huawei aluminium is one of the trustworthy 5005 aluminum sheet suppliers in China with more than 20 years experiences on aluminum product export industry. Similar to 3003 alloy, 5005 aluminum alloy has medium strength and good corrosion resistance. 5005 aluminum sheet alloy is used as conductor, cookware, instrument panel, shell and architectural decoration. The anodized film of 5005 aluminum sheet is brighter ...

The internationally registered aluminum alloy grades consist of more than 1000, each of which has a variety of states and has a very different effect in terms of function and performance. It is necessary to make reasonable material selection according to the performance requirements of the products, the use environment, the processing engineering, the priority of performance and other factors. Commonly used al ...

The 5052 aluminum plate and the 5754 aluminum plate belong to the 5 series aluminum plate sequence. The primary alloy design elements of the two are the same as the magnesium-aluminum aluminum plate, but there are still certain differences between the two products. The reason for this difference is due to the alloy composition. Caused by the difference. The magnesium content of 5052 aluminum plate is slightly hi ...

Aluminum alloy plate is the main metal material in the world. The development of aluminum processing industry is supported by downstream real estate, automobile, railway transportation and power grid. According to the analysis, aluminum for transportation has become a new economic growth pole of the aluminum industry, and the growth rate of aluminum demand will exceed 8%. Metal materials are used in the constr ...