What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

Parameters of aluminum sheet plates for auto Alloys: 1060, 3003, 5005, 5052, 5182, 6061 ( aa6016 ) etc Where is the aluminum plate used in the car? Ordinary automotive aluminum sheet 1 Automobile chassis 5000 series or 6000 series materials. 2 Car skeleton the most stressed part of the body, is made of 2000 series or 7000 series materials, which can be strengthened by heat treatment. ...

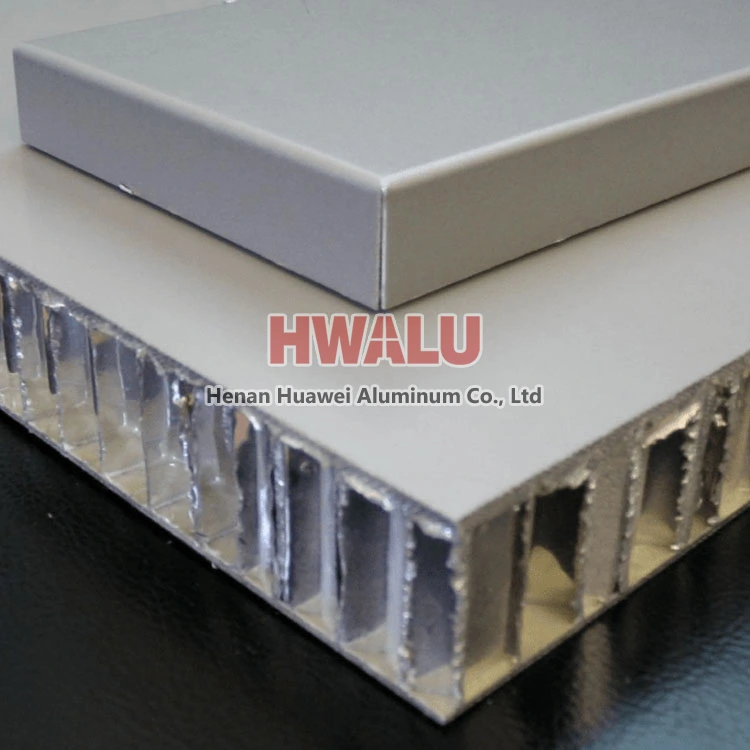

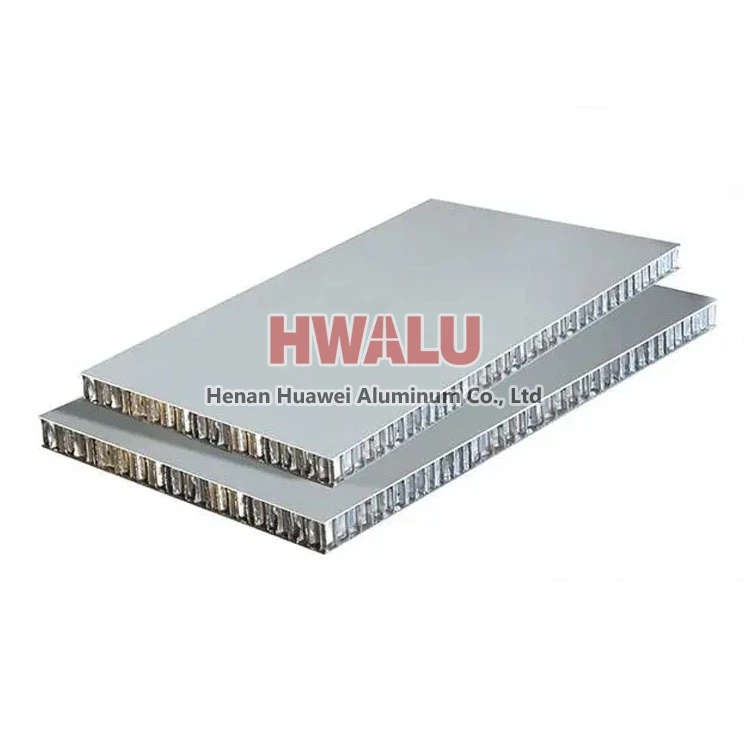

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

Introduction of Stucco Embossed Aluminum Sheet Welcome to Huawei Aluminum, your premier destination for high-quality stucco embossed aluminum sheets. Our dedication to excellence in manufacturing and wholesaling aluminum products is unmatched, ensuring that every sheet we deliver meets the highest standards of quality and performance. Stucco embossed aluminum sheets are known for their robustness, versatility, a ...

What is 18 gauge aluminum sheet? 18 gauge is a way of expressing the thickness of aluminum sheet, which is typically about 0.0403 inches (or about 1.02 mm) thick. This is a common specification for a variety of aluminum applications, including automotive panels, signage and lightweight structural components. 18 gauge aluminum sheet equivalent expression 18 ga aluminum sheet 18 gauge aluminium sheet ...

In the kneading process of aluminium plate, there will be skin or bubbles on the surface. What is the cause of formation? What can be done to eliminate it? What is bubble or peeling: convex bubbles appear on the appearance of products, often seen in the head, and tail, completely called bubbles, which have been broken called peeling. Aluminum plate kneading bubble, peeling reason. Kneading cylinder and ...

Among the 1000 to 8000 alloy series, the 7000 series aluminum alloy is a heat treatable alloy, belonging to the aircraft series, and belongs to a relatively high-end field in aluminum sheets. The 7075 aluminum sheet is a representative product of the 7000 series, it is aircraft aluminum sheet with aluminum magnesium zinc copper alloy, can be heat treatable, has super hard ability and good wear resistance.7075 ...

5083 aluminum plate: 5083 aluminum plate is a high-strength aluminum alloy plate with excellent corrosion resistance and tensile strength, which is widely used in ships, automobiles, aircraft, electronics and other fields. 5754 aluminum plate: 5754 aluminum plate is a medium-strength aluminum alloy plate with good corrosion resistance and weldability, and is widely used in ships, vehicles, construction and ...

There are many anodic oxidations for aluminum alloys, which can be used in daily life. Because of the characteristics of this process, a hard protective layer is produced on the surface of aluminum parts, which can be used to produce kitchen utensils and other daily necessities. However, the anodizing effect of cast aluminum is not good, the surface is not good, and it can only be black. The aluminum alloy profil ...

Aluminum is one of the metals most widely used in industry and daily life, when it comes to the aluminum alloy, the 1000 series aluminum sheet come to our mind, there are two typical aluminum sheet in 1000 series aluminum sheet alloy, they are 1050 aluminum sheet and 1060 aluminum sheet, they are all with high content of aluminum, they looks like the same, but their types are different, what is the difference bet ...

The scientific name of aluminum-plastic panel is also called aluminum-plastic composite panel. It is a three-layer composite panel with plastic as the star layer and aluminum on both sides, and a decorative and protective coating and film on the surface of the panel. Material. The common size on the market is 2 meters 44 times 1 meter 22, of course, other sizes can also be customized according to customer requir ...