what is 6063 aluminum sheet? 6063 aluminum sheet is Al-Mg-Si alloy, with excellent processing performance, excellent solderability, extrusion and plating, good corrosion resistance, toughness, easy polishing, anodizing Excellent effect, is a typical extruded alloy. 6063 Aluminum sheet is widely used in construction profiles, irrigation pipes, vehicles, benches, furniture, lifts for its good plasticity. Mi ...

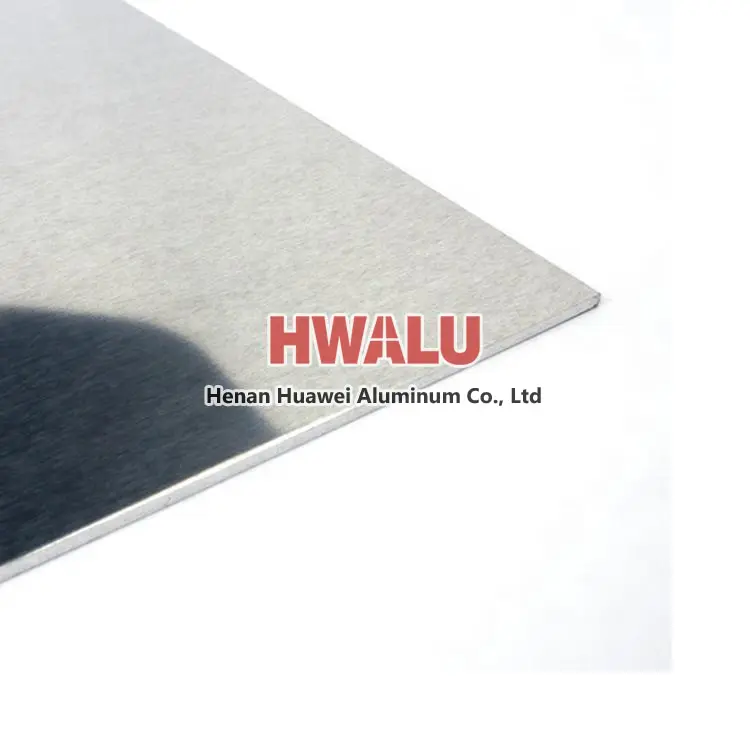

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

063 Aluminum Sheet introduction The ‘063 Aluminum Sheet’ refers to an aluminum sheet with a thickness of 0.063 inches, which is approximately 1.60mm. This type of sheet is known for its versatility and is commonly used in various applications due to its favorable properties such as corrosion resistance, good machinability, high strength after heat treatment, light weight, good weldability, and the ability to be ...

What is 18 gauge aluminum sheet? 18 gauge is a way of expressing the thickness of aluminum sheet, which is typically about 0.0403 inches (or about 1.02 mm) thick. This is a common specification for a variety of aluminum applications, including automotive panels, signage and lightweight structural components. 18 gauge aluminum sheet equivalent expression 18 ga aluminum sheet 18 gauge aluminium sheet ...

Aluminum sheet plate refers to aluminum material with a thickness of 0.2mm over to less 500mm. Classification by thickness Thin aluminum sheet plate Standard thickness aluminum sheet plate Medium thickness aluminum plate Thick aluminum sheet plate Super thick aluminum sheet plate Different thickness aluminum sheet determines its different functions. And different functions can be used in diff ...

The cost of hot rolling is higher than that of cast rolling. However, the difference between them is not just a matter of production cost. The maturity level of hot rolling technology and equipment control level are far higher than those of cast-rolled products. Moreover, hot rolling is rolled within the recrystallization temperature range of aluminum alloy without alloy composition. Restriction, which means that ...

Aluminum 6061 T4 Sheet is solution heat treated and naturally aged giving it slightly lower tolerance accuracy than Aluminum 6061 T6, which undergoes artificial aging. T4 is also slightly less expensive than T6 and has a slightly lower ultimate tensile strength and yield strength, with a higher elongation percentage, which increases the formability of the T4 temper. Aluminum sheet 6061 T4 is also cost friendlier ...

The first four digits "6061" represent the grade. The "T6" at the back represents the processing state, which generally has 2-3 digits and numbers, and there are five common aluminum alloy processing states. The first digit indicates the alloy element, "6" refers to the 6-series aluminum-magnesium-silicon alloy. The second digit indicates the number of reshaping, "0" refers to the original alloy, no special ...

Aluminum or aluminum alloys are strong corrosion-resistant materials. These alloys have sensitivity to high temperatures that range from 200 to 250 degrees Celsius, earning themselves the description, good low-temperature alloys. Their strength increases upon exposure to subzero temperatures and strength is diminished and lost upon exposure to high temperatures. ALUMINUM 2024 Aluminum alloy 2024 is an alumi ...

1. One of the factor: emulsion concentration (C)The influence of the emulsion concentration on the rolling surface is realized by the thickness of the oil film formed in the deformation zone. The concentration is too low and the oil equivalent precipitated in the deformation zone is low. The thickness of the oil film forming the minimum fluid lubrication must be 3 times the combined surface roughness. High concen ...

Aluminum plates are widely used in engineering decoration, home decoration, communication electronics, transportation facilities, heat preservation and corrosion protection, fine decoration, automobile manufacturing and other fields. So, what are the knowledge points in the use of aluminum plates? Aluminum plate use Aluminum plate storage: It should be stored in a dry and ventilated place, and placed flat on ...