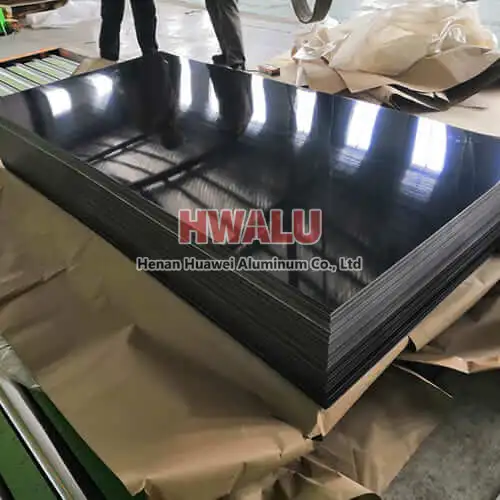

What is Black Aluminum Sheet Black aluminum sheet refers to an aluminum sheet that has a black effect after surface treatment. This type of aluminum sheet is processed through a series of surface treatment processes on the basis of the original aluminum material. It has a wide range of uses, including architectural decoration, furniture manufacturing, and home appliance panels. It can also be used as parts and c ...

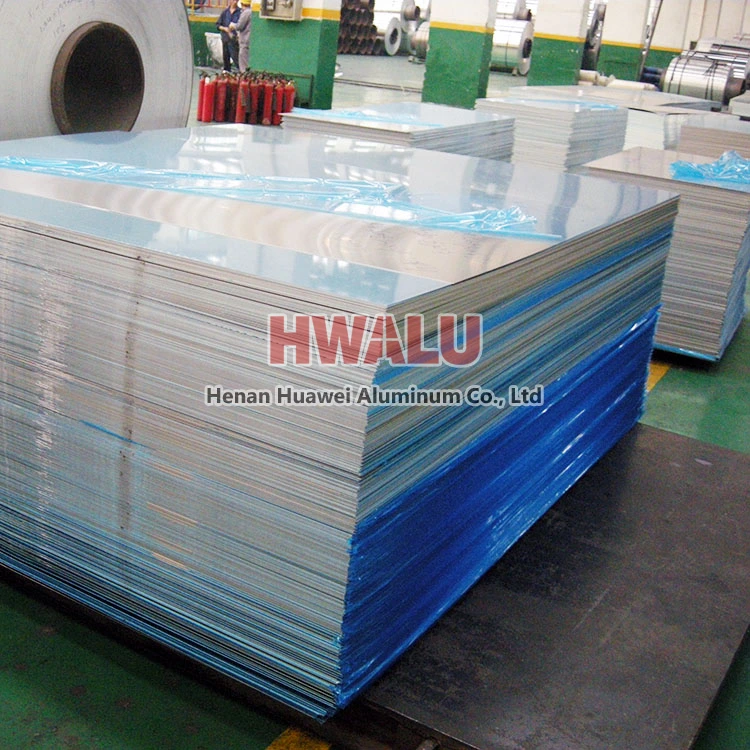

The most typical use of aluminum sheet for wall is aluminum curtain wall. The aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plates. Its common thickness is 1.5, 2.0, 2.5, 3.0MM, the model is 3003, and the state is H24. wall sheet Parameters of aluminum plain sheet plates for wall There are generally four thicknesses of curtain wall aluminum veneer: 1mm thickness, ...

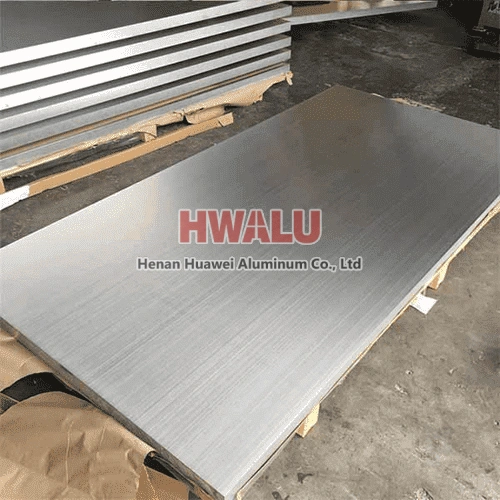

What is "gauge" meaning for aluminuum sheet? In the context of aluminum sheets, “gauge” refers to the thickness of the sheet. It’s a standardized measurement system used to indicate the thickness of an aluminum sheet metal. There are two gauge systems used for aluminum sheets: American Wire Gauge (AWG): Ranges from 8 to 30, with the higher numbers indicating thinner sheets. Standard Wire Gauge (SWG): ...

What is 18 gauge aluminum sheet? 18 gauge is a way of expressing the thickness of aluminum sheet, which is typically about 0.0403 inches (or about 1.02 mm) thick. This is a common specification for a variety of aluminum applications, including automotive panels, signage and lightweight structural components. 18 gauge aluminum sheet equivalent expression 18 ga aluminum sheet 18 gauge aluminium sheet ...

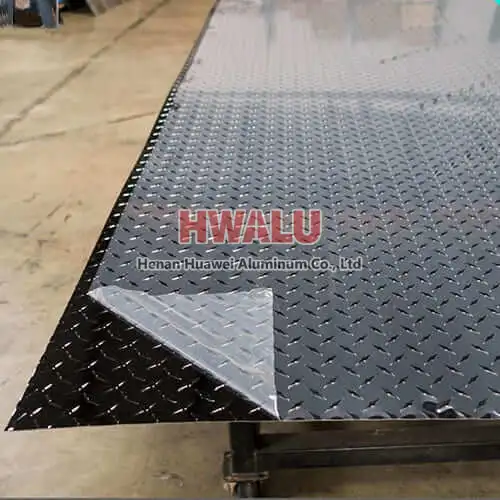

What is black aluminum checker plate Black aluminum checker plate, also known as black aluminum tread plate or black aluminum diamond plate, is an aluminum sheet with a raised diamond pattern on one side. This pattern provides slip resistance and is commonly used in various applications where traction and durability are required, such as truck beds, trailers, stairs, ramps, and industrial settings. The black ...

Aluminium alloy 5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres. It has higher strength than 5251. This high strength makes 5754 highly suited to flooring applications. 5754 h111 aluminum sheet Applications: 5754 is typically used in: ~ Treadplate ~ Shipbuilding ~ Vehicle bodies ~ Rivets ~ Fishing industry equipment ~ Food processing ...

Deep processing mode: 1. Surface treatment: pickling, alkali washing, organic liquid cleaning, polishing, polishing, sandblasting, electroplating, anodic oxidation, electrolytic coloring, coating (roll coating, spraying), printing, embossing, drawing, etching; 2. Hardware stamping class: punching, flanging, flanging, curling, bending, stamping, expanding, spinning, flaring, shrinking, rolling, drawing, thin ...

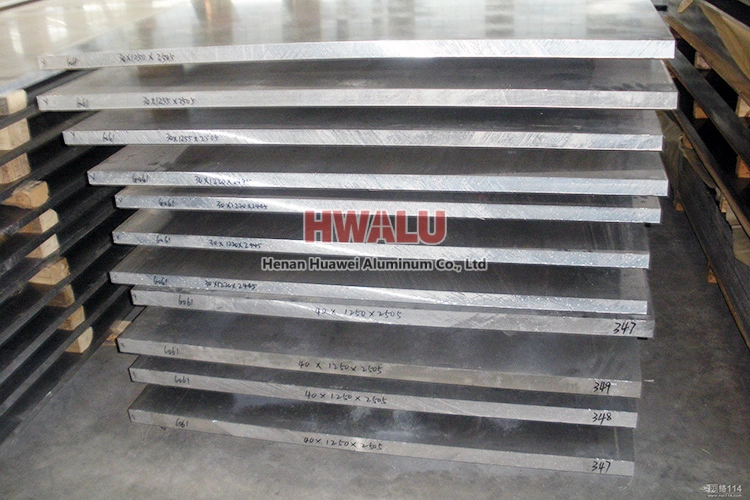

Hot rolling mill aluminum sheet generally refers to the rolling of metal above the crystallization temperature. Compared with ordinary cast-rolled products, hot-rolled aluminum sheet has good surface quality, while the mechanical properties as well as ductility are stronger and oxidation effect is good. Cold rolling aluminum sheet is also called cast aluminum sheet, cold rolling usually refers to the rolling o ...

We offer a great selection of aircraft aluminium sheet in a variety of specifications. The mechanical properties of an alloy are an important factor in the decision where to use it during construction.Look through our extensive assortment of aircraft aluminum sheet here .With its good strength to weight and cost ratio, aluminum is still used very widely in the industry,Aluminum sheets become to be the king in air ...

A variety of small defects often appear on the surface of aluminum plates, such as unevenness, fracture, uneven thickness, etc. What are the reasons for these defects? Now the aluminum plate manufacturer will answer you one by one from the following seven aspects Bar: 1. The roll shape of the aluminum plate is incorrectly folded (folded), such as heating of the calender bearing; 2. Air bubbles on the surface of ...