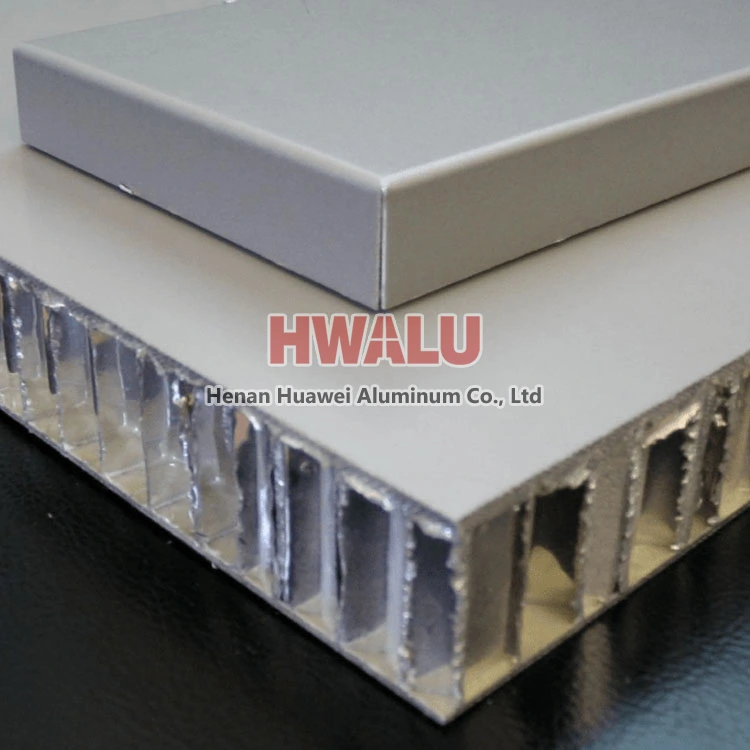

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

Price list of aluminum plates for door Date:Based on January 5th,2022 SMM Price 2570.39USD Date LME LME Weekly Price 2022-12 LME Average 2022-12 SMM Average 2022-12-26(Monday) / 2358.33$ 2394.88$ 2721.60$ 2022-12-27(Tuesday) / 2022-12-28(Wednesday) 2343$ 2022-12-29(Thursday) 2371.5$ 2022-12-30(Friday) 2360.5$ Notes 1. Prices are updated at 10:00 am on weekd ...

063 Aluminum Sheet introduction The ‘063 Aluminum Sheet’ refers to an aluminum sheet with a thickness of 0.063 inches, which is approximately 1.60mm. This type of sheet is known for its versatility and is commonly used in various applications due to its favorable properties such as corrosion resistance, good machinability, high strength after heat treatment, light weight, good weldability, and the ability to be ...

what is 6000 series aluminum sheet? 6 series aluminum alloy mainly contains two elements of magnesium and silicon, also known as "aluminum-magnesium-silicon alloy", is a heat treatment type of corrosion-resistant aluminum alloy, with high strength and corrosion resistance, good uniformity, excellent processing performance, excellent welding characteristics and plating, good corrosion resistance, high toughness a ...

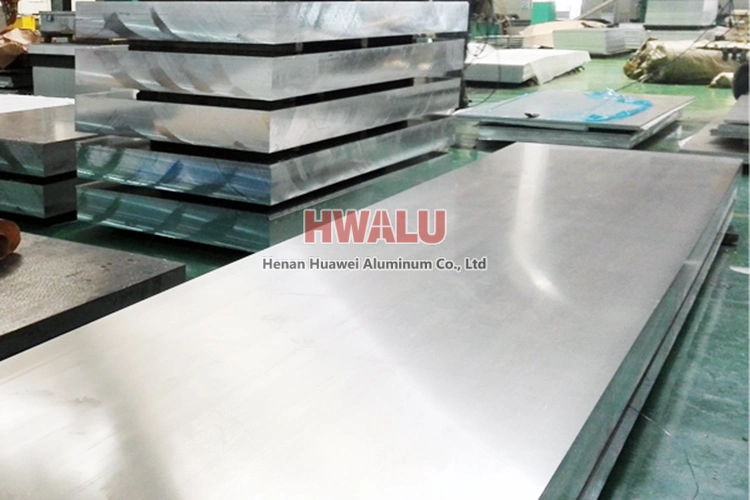

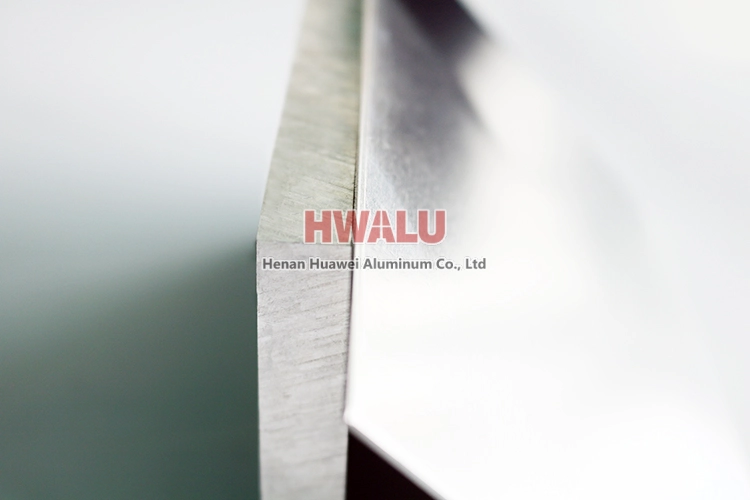

6mm aluminum sheet introduction 6mm aluminum sheet is a kind of metal material commonly used in industry and manufacturing. With a thickness of 6mm, it is made of pure aluminum or aluminum alloy by pressure processing (such as rolling), with rectangular cross section and uniform thickness. Aluminum sheet is widely used in many industries because of its light weight, corrosion resistance, good conductivity and st ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

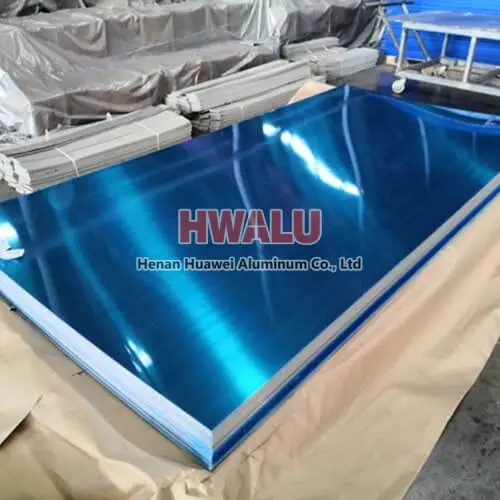

Which aluminum sheet supplier is better? Huawei Aluminum says so In recent years, high-strength, low-density, and corrosion-resistant aluminum sheets have become popular in the market, but where to choose the right aluminum sheet and how to find a reliable aluminum sheet supplier has made many people difficult. Which aluminum sheet supplier is better? Warwick Aluminum said so. Henan Huawei Aluminum Co., Ltd. ...

The surface of the aluminum plate is smooth and flat without corrugation and unevenness. It is a product made of cast-rolled billets through pressure rolling. The patterned aluminum plate is made of aluminum plate or aluminum coil through embossing equipment. It can be understood as aluminum ingot production into aluminum plate, aluminum plate It is embossed and processed into a patterned aluminum plate. Because ...

1. Aluminum and aluminum alloy plates and strips are supplied in hot rolled state, annealed state, various levels of soft state and various heat treatment states. 2. Preparation before hot rolling It mainly includes ingot quality inspection, soaking, sawing, milling, aluminum coating and heating. 3. The cooling rate is very high during semi-continuous casting, the diffusion process in the solid phase is dif ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. 5052 aluminum sheet is often referred to as "Anodize Quality Aluminum", as it has excellent finishing qualities and anodized coatings are bright and clear. The major alloying element in 5052 is magnesium in sufficient quantities to caus ...

Aluminum alloy No. 1050, H stands for work hardening state, Hxx state description: The first digit 1 stands for simple work hardening state, suitable for the required strength without additional heat treatment, only work hardening. The second digit represents the hardened state, the number 0 represents the annealing, ie the soft state, 8 represents the hard state, 9 represents the super-hard state, and the number ...