Introduction of Aluminum Sheet Plates for Heat Sinks At Huawei Aluminum, we specialize in manufacturing high-quality aluminum sheet plates designed for optimal heat dissipation. Our products are engineered to meet the rigorous demands of modern electronic devices, ensuring efficient thermal management and enhanced performance. Why Choose Aluminum for Heat Sinks? Aluminum is the material of choice for heat sink ...

How is embossed aluminum sheet produced Select aluminum material: first select the aluminum plate that meets the requirements. Commonly used aluminium materials include aluminum alloy plate, pure aluminum plate, etc., and their thickness is generally between 0.5mm-3mm. Surface treatment: The surface of the aluminium plate is cleaned, degreased, pickled, etc. to remove impurities such as oil and scale to e ...

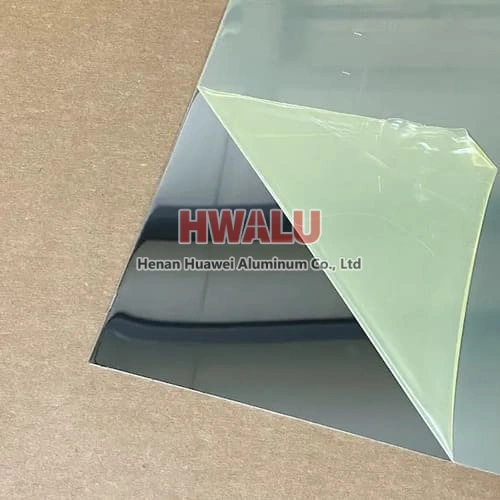

What is reflective aluminum sheet? What is aluminum sheet reflector? Reflective aluminum sheet, also known as mirror aluminum sheet or reflective aluminum, is a type of aluminum sheet. It has reflective surfaces that reflect light and heat. It has high reflectivity, also known as high reflective aluminum sheet. Reflective aluminum sheet refers to a thin and flat aluminum material that has been specially treated ...

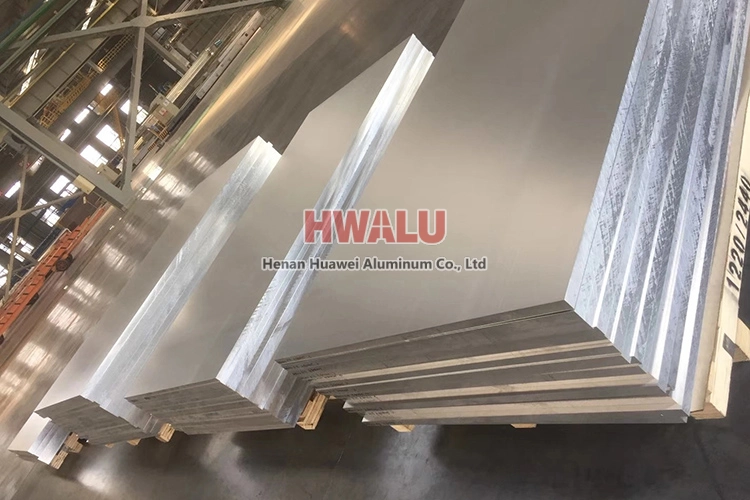

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

what is 7075 aluminum sheet? 7075 alloy metal aluminum sheet plate is a common alloy in 7000 series aluminum alloy sheet. 7075 aluminum sheet (Al-Zn-Mg-Cu) belongs to super-hard aluminum. As a kind of cold finished wrought alloy, it has great strength and hardness. It’s far better than mild steel. This alloy has good mechanical properties and anode reaction. 7075 aluminum sheet as a typical kind of aerospace al ...

Aluminum alloy structure has been gradually used in the construction industry, from the initial aluminum alloy doors and windows to the current aluminum alloy mesh structure, aluminum alloy materials have been applied in a large number of building structure projects, and there are various forms of building structures suitable for aluminum alloy. Aluminum alloy structure is also used in bridges, roofs and civil ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

5052 H32 Aluminum Sheet - Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc. What's the Application of 5052 aluminum sheet? Building, curtain wall, ceiling, panels, transformers, food packaging, air conditioning, ...

7075-T6 aluminum is 7075 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 7075-T6 aluminum to: 7000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the re ...

Forging 6063 aluminium sheet coil can be done using a temperature set between 750 and 900 degrees Fahrenheit. Temperatures to use for hot working should be between 500 and 700 degrees Fahrenheit. Any common welding technique can be used for this metal. If annealing is needed, it should be performed continuously at 775 degrees Fahrenheit for between two and three hours, then provide controlled cooling at 50 deg ...

3004 aluminium alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose allo ...