What is a 5mm aluminum plate? 1 inch = 25.4 mm 5mm = 5/25.4 inches = 0.197 inches=0.197''=.197in The 5mm aluminum plate is an aluminum plate with a thickness of 5mm, and the length and width can be customized according to the customer's specifications. The 5mm aluminum plates we produce: curtain wall aluminum plate, checkered plate (embossed aluminum plate), mirror plate, anodized aluminum plate, 1 series ...

Definition of 4mm aluminum sheets A 4mm aluminum sheet, also known as an aluminum plate, is a panel of aluminum that is 4 millimeters thick. It’s a result of basic raw-form aluminum being pressed and rolled into panel form under high pressure. Aluminum sheets are characteristically manufactured to be very thin and lightweight, yet sturdy enough to offer extreme versatility alongside inherent ease of installat ...

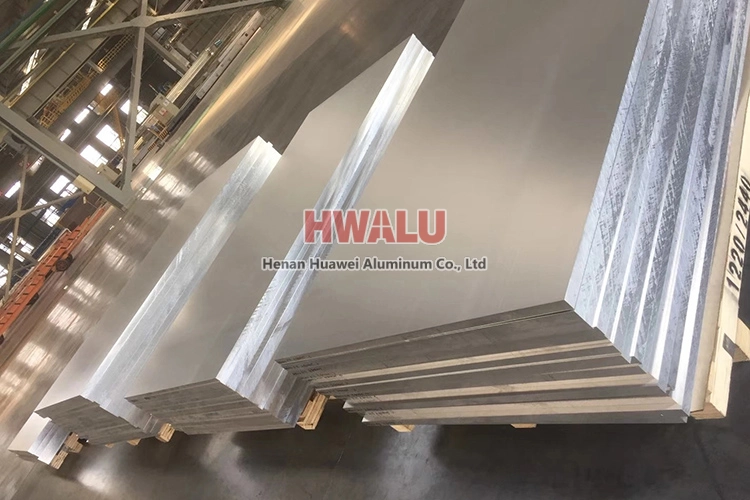

Medium thickness aluminum plate refers to aluminum plates with thick between 6mm ~ 25mm. For example, the commonly used aluminum plate thicknesses are 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 12.7mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm, 21mm, 22mm, 23mm, 24mm etc How to choose the medium and thick aluminum plate correctly The material of the medium and thick aluminum plates is relatively large, and many users ...

What is polished aluminum sheet? Polished aluminum plate is a high-gloss aluminum plate with a polished and oxidized surface. Polished aluminum sheet is usually an aluminum sheet that is processed by rolling, polishing and other methods to give the surface of the sheet a mirror effect. This treatment can not only improve the surface finish and corrosion resistance of the aluminum plate, but also remove oxides an ...

Introduction The thickness of a 1 16 aluminum sheet is exactly that—1/16 of an inch. In decimal terms, this is equivalent to 0.0625 inches. In millimeters, it translates to approximately 1.59 mm. It’s a commonly used thickness for a variety of applications due to its balance of flexibility and strength. The 1 16 aluminum sheet is a popular material choice across industries due to its versatility, durability, ...

Both 5052-H32 aluminum and 5052-H34 aluminum are variants of the same material. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing. 6061 aluminum sheet alloy is strong, easily machined, and weldable. Aluminum 6061 T6 alloys are doubled the strength of aluminum 6063 alloys. Aluminum 6061 has an ultimate tensile strength of a ...

Today we will learn about aluminum veneer. In fact, this aluminum veneer refers to a single aluminum plate that is processed by cutting-engraving-stamping-welding-grinding and other processes. The fluorocarbon spraying technology is used to form a building decoration material. This material is widely used in various buildings. Internal and external walls, airports, stations, hotels, offices, hospitals and other ...

Alloy temper Coefficient of thermal expansion (20)μm/m.k Melting point range(℃) Conductivity ( %IACS ) Resistivity Ωmm2/m Density (g/cm3) 5052 H112 23.2 500 - 635 30 0.058 2.82 5083 H112 23.8 607 - 650 35 0.050 2.72 6061 T651 23.4 570 - 640 29 0.059 2.72 7050 T7451 23.6 580 - 650 43 0.040 2.73 7075 T651 23.5 490 - 630 41 0.0415 2.82 2024 T351 23 ...

Aluminum alloy structure has been gradually used in the construction industry, from the initial aluminum alloy doors and windows to the current aluminum alloy mesh structure, aluminum alloy materials have been applied in a large number of building structure projects, and there are various forms of building structures suitable for aluminum alloy. Aluminum alloy structure is also used in bridges, roofs and civil ...

3004-H32 aluminum is 3004 aluminum in the H32 temper. To achieve this temper, the metal is strain hardened, and then stabilized, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H38). It has the second highest ductility compared to the other variants of 3004 aluminum. The graph bars on the material properties cards below compare 3004-H32 aluminum to: 3000-series alloys (top), ...

3004 aluminum sheet is a non- heat treatable aluminum alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. the 5052 aluminum alloy is used to make beverage closure without internal pressure. The raw material is 5052 H19 aluminum sheet, the material is fir ...