2mm aluminium sheet price 2mm aluminium sheet price can vary depending on several factors such as the grade of aluminum, the supplier, the quantity ordered, and the location of the supplier. On average, a 2mm thick sheet of aluminum can cost between $2 and $10 per square foot. the way to cut a 2mm aluminum sheet 1. For thin aluminium plates below 0.1mm, use a utility knife or paper cutter, and it is easy to ...

Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

Where to buy anti-rust aluminum sheet? Take you to understand Antirust aluminum sheet Antirust aluminum sheet refers to an aluminum sheet containing a certain amount of manganese alloy and magnesium alloy. Among all the series of aluminum sheets, the three-series and five-series aluminum sheets are mainly called Antirust aluminum sheets, because a proper amount of manganese alloy and magnesium alloy is ad ...

What is diamond aluminum sheet? Diamond aluminum plate, also known as diamond plate or diamond pattern plate, is an aluminum plate with a raised diamond pattern on one side. The diamond-shaped aluminum plate pattern provides increased traction and durability, making it ideal for applications where slip resistance is important, such as industrial floors, stairs, ramps and truck beds. Aluminum diamond sheet c ...

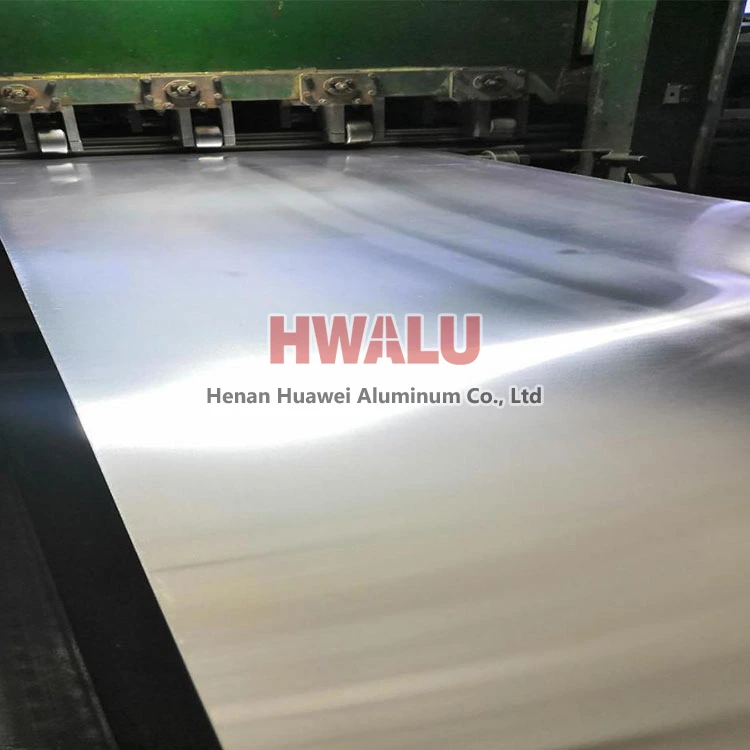

Aluminum sheet plate refers to aluminum material with width of 200mm over, and length of less 16000m. Custom Sizes 1 foot = 12 inch = 304.8 mm, 4 feet = 48 inches = 1220 mm Unit ( foot ): 4x4, 4x6, 4x8, 4x10, 4x12, 5x8, 6x8 etc Unit ( inch ): 12x12, 24x24, 24x36, 24x48, 36x36, 48x48 etc Hot sales sizes 4x8 foot aluminum sheet plate 5x8 ft ( 5 x 8 ), 60x96 inch ( 60 x 96 ), 1524 x 2438.4mm ...

Aluminum alloy structure has been gradually used in the construction industry, from the initial aluminum alloy doors and windows to the current aluminum alloy mesh structure, aluminum alloy materials have been applied in a large number of building structure projects, and there are various forms of building structures suitable for aluminum alloy. Aluminum alloy structure is also used in bridges, roofs and civil ...

7075-T6 Aluminum Sheet is primarily used in aerospace industry, often referred to as the Strongest Aluminum grade. Alloy 7075 has the strength of many steels, while retaining aluminum’s lightweight qualities. 7075 aluminum sheet has a high strength to weight ratio. 7075 parallels the use of 2024 when higher mechanical properties are desired. Because of this it is used for highly stressed structural parts. It i ...

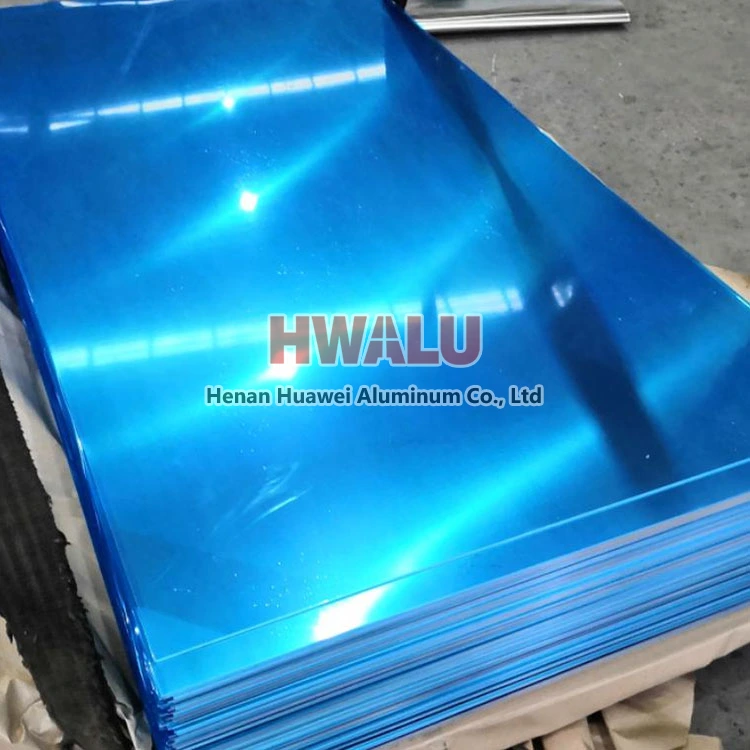

Color coated stucco aluminum plate also called as color coated embossed aluminum plate, the common seen embossed patterns on the surface are orange peel and rhombus/diamond pattern, the surface coating are fluorocarbon and polyester paint, the paint has various colors like white, black, red, green, blue, gray, yellow, gold and so on. The specification of color coated stucco embossed aluminum are:Alloys: 1050, ...

1. Cut corners With the continuous improvement of the national quality control system, the phenomenon of cutting corners is not as rampant as before. However, in order to reduce production costs, there are still some companies who take risks by cutting corners and using molds of substandard quality in the process of producing aluminum veneer products. , Resulting in unqualified wall thickness of the aluminum p ...

In recent years, the production and sales volume of flat-panel TVs has grown rapidly, and the market demand for 5052 h32 aluminum sheet for producing plasma display backing heat sinks panel has also increased rapidly. The surface of the LED back plate is required to be clean and delicate, uniform in color, and it is not allowed to have cracks, corrosion, vent holes, peeling, metal and non-metal indentations, s ...

Aluminum is a common light metal with many unique properties, one important of which is its relatively low melting point. First, we need to understand the basic properties of aluminum. Aluminum has an atomic number of 13 and an atomic weight of 26.98. It is silvery white, soft, malleable, and conductive. Aluminum has a melting point of 660.32°C, which is lower than many other metals such as iron and copper. ...