Premier 0.8mm Aluminum Sheet Factory and Wholesaler Introduction Welcome to Huawei Aluminum, your trusted source for high-quality 0.8mm aluminum sheets. Our precision-engineered sheets are crafted to meet the diverse needs of various industries, offering durability, versatility, and performance. Product Overview Our 0.8mm aluminum sheets come in a range of alloy models, each tailored for specific applic ...

Introduction At Huawei Aluminum, we specialize in the production and wholesale of high-quality 3mm aluminum sheets. Our products are renowned for their durability, corrosion resistance, and versatility in various industries. With a wide range of alloy models and specifications, our aluminum sheets cater to diverse applications from construction to aerospace. Key Features Durability: Our 3mm aluminum sh ...

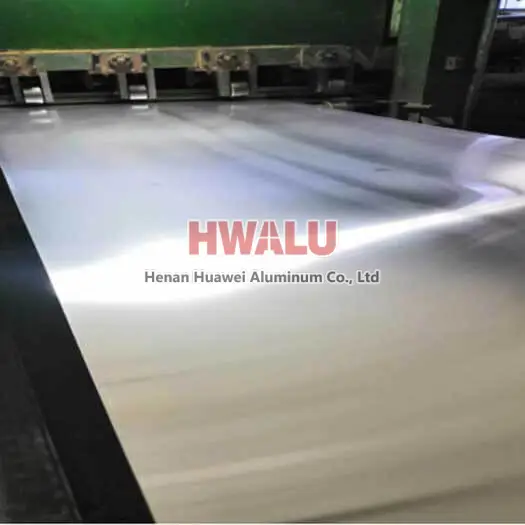

Thin aluminum sheet refers to aluminium sheets with thick between 0.15mm ~ 2mm. The parameters of 5052 thin aluminum plate as an example are for reference only. If you want to know more about the thin aluminum plate, please contact us as soon as possible. Alloy State Thickness Width Tensile strength (Mpa) Elongation (δ%)(Scaling distance 50) 5052 0 >0.5~1.3 >1.3~4.5 Above 500mm ...

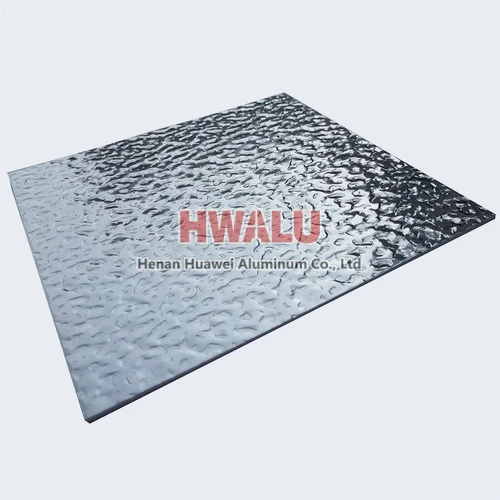

4x8 aluminum checker plate product The 4x8 aluminum checker plate is a popular type of metal plate that features a raised pattern on the surface of the aluminum plate. Aluminum pattern plates not only retain the excellent characteristics of ordinary aluminum alloy materials, such as excellent corrosion resistance and weather resistance, but also have some special properties, such as anti-skid, wear-resistant, an ...

Super thickess aluminum plate refers to aluminium plates with thick between 200mm ~ 500mm. For example, the commonly used aluminum plate thicknesses are 200mm, 250mm etc

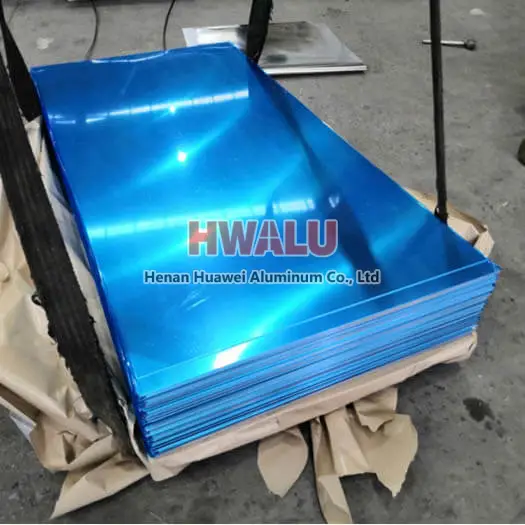

Huawei aluminium aluminum is one of the aluminum for pp caps closures 3105 manufacturers in china which is integrate, design and sales. The 3105 aluminum closure sheet for pp caps material produced by Huawei aluminium are flat and geometric in size. At the same time, the surface gloss is high and the alkali washing effect is good, and the brushing water test A grade can be achieved. The surface of the 3105 alu ...

1060 aluminum sheet is another representative product in 1000 series aluminum alloys. 1060 aluminum alloy is formed by pure aluminum added by a small amount of copper element, which has excellent forming processing characteristics, high corrosion resistance, good weld ability and conductivity. The same as 1050 aluminum sheet, the aluminum sheet 1060 is widely used in products with low strength requirements, such ...

Aluminium 5083 alloy for boat has been used in the ship building industry for nearly 100 years. With the rapid development of the shipbuilding industry at home and abroad, the lightweight of ships like sailboat has been paid more and more attention. Due to the low density, ships constructed from marine grade aluminum are 15-20% lighter than ships constructed from steel or other synthetic materials, which is a ...

There are many aluminum sheet manufacturers and the level is uneven. The manufacturers that can produce high-quality aluminum sheets are rare. So, before asking the 1100 aluminum sheet price, we’d better know about the product quality first. The quality of 1100 aluminum sheet is affected by the manufacturing process directly. The so-called aluminum sheet manufacturing process is a process of aluminum alloy int ...

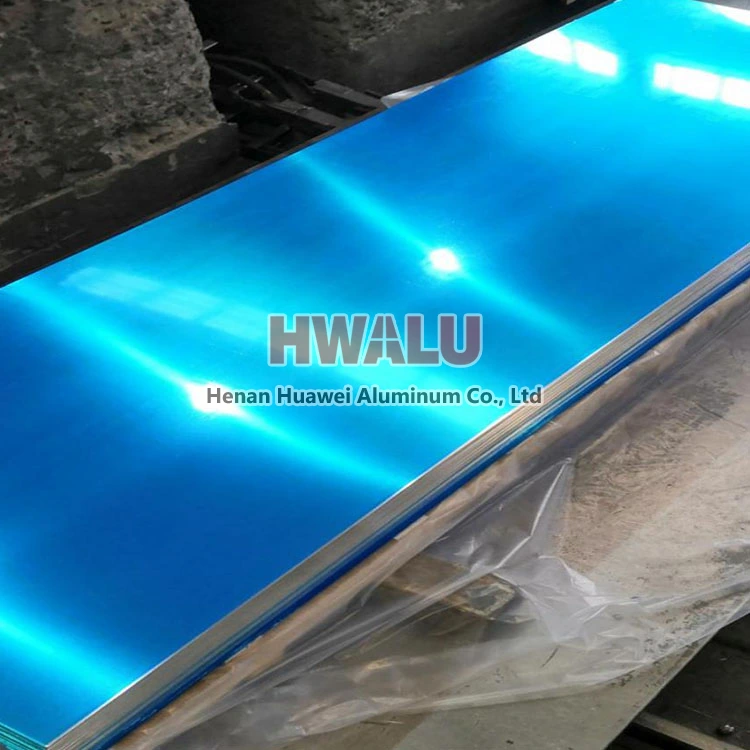

Aluminum sheets for traffic signs are usually made of aluminum alloy sheets with other elements added. Usually, an aluminum plate coated with a layer of colored paint is used as a sign, most of which are blue, green, and yellow aluminum plates. Because of its good reflection effect and corrosion resistance, the color-coated aluminum sheet is widely used in the field of traffic signs to remind pedestrians and vehi ...

3004 aluminum plate :3004 series aluminum plate also belongs to a series of aluminum manganese alloy, the strength is higher than 3003, excellent formability, good corrosion resistance, the component strength is higher than 3003 alloy. 3004 is an aluminum-manganese alloy, which is the most widely used antirust aluminum. The alloy has a low strength (slightly higher than industrial pure aluminum) and cannot be ...