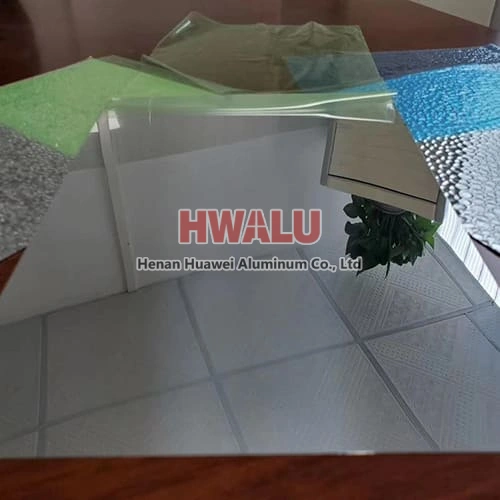

What is reflective aluminum sheet for lighting Reflective aluminum sheets for lighting are typically made from high-quality aluminum with a highly reflective surface. These sheets are designed to reflect light efficiently, making them ideal for various lighting applications. In lighting, reflective aluminum sheets are commonly used in fixtures and reflectors to direct and enhance the light output. The reflect ...

What are the two types of aluminum anodizing? There are two main types of aluminum anodizing: sulfuric acid electrolytic oxidation and hard anodizing. Sulfuric acid electrolytic oxidation is a conventional anodic oxidation method, which uses sulfuric acid as the electrolyte to form an oxide film on the surface of aluminum by means of electricity. This oxide film has certain protective and decorative propertie ...

What does the 4x8 in the 4x8 foot aluminum plate mean? In general, 1'=1 foot (symbol ft) = 12 inches (12") = 30.48 cm = 304.8 mm 1"=1 inch ( inch is abbreviated as in or " ) = 2.54 cm = 25.4 mm (actual value is 2.539999918 cm.) So, 4 in 4 x 8 foot is 4 x 304.8 mm = 1219.2 mm = 1.2192 m ≈ 1220mm ≈ 1.22 m 8 in 4 x 8 feet is 8 x 304.8 mm = 2438.4 mm = 2.4384 meters ≈ 2440mm ≈ 2.44 m i.e. 4x8 foot = 1.22m ...

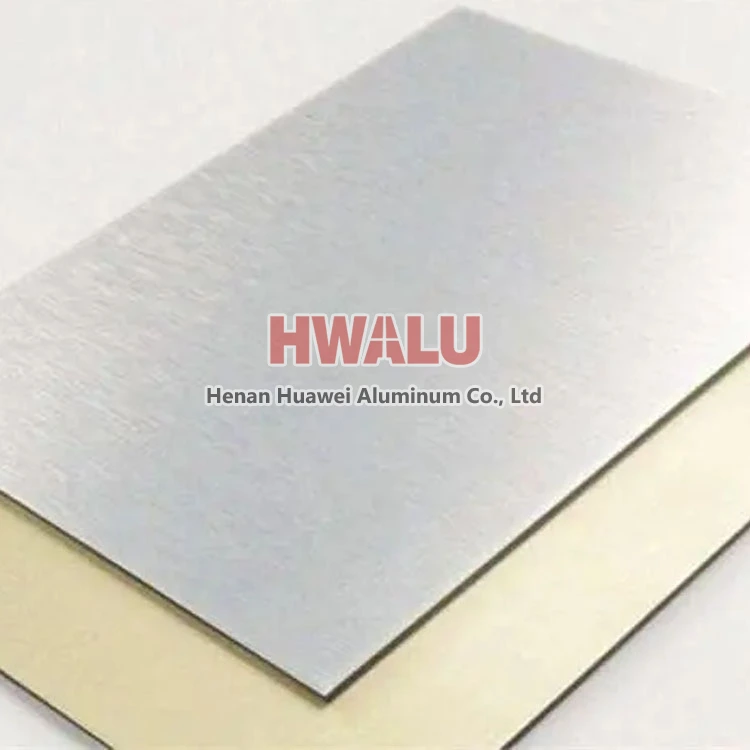

0.5mm aluminum sheet brief description 0.5mm aluminum sheet is a common metal material in industry and manufacturing. Its basic feature is that it is a rectangular plate with a thickness of 0.5mm, which is rolled and processed from aluminum or aluminum alloy. Aluminum sheets of this thickness are lightweight, highly corrosion-resistant, have good electrical and thermal conductivity, and are widely used. Advanta ...

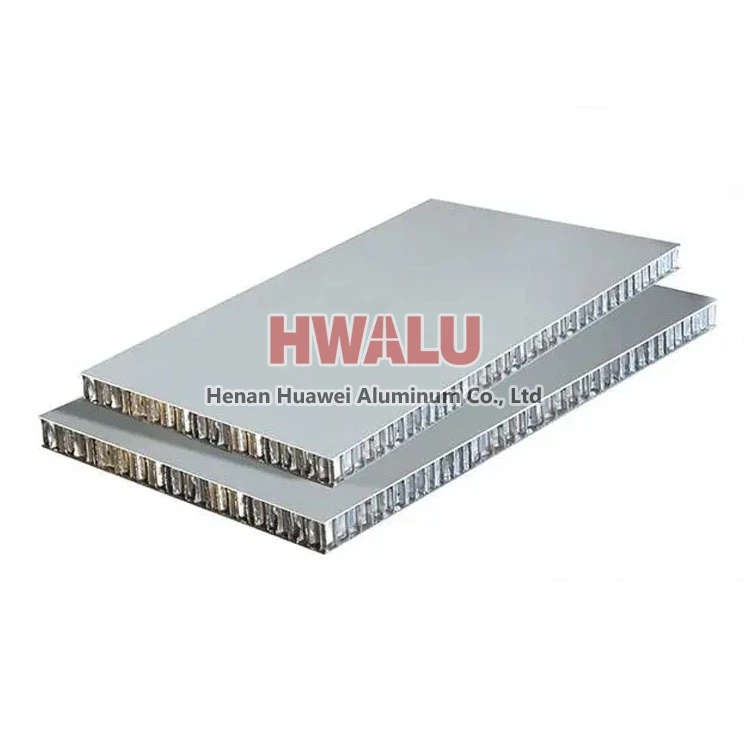

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

The difference between 6061 T5 and 6061 T651 aluminum sheet.What is the difference between 6061 T5 and 6061 T651 aluminum sheet?The 6000 series represents 6061 aluminum, which contains mainly magnesium and silicon. It is a cold-treated aluminum forging product with the advantages of 4000 Series and 5000 Series.The difference between the state T6 and T651 of 6061 aluminum sheet is that the internal stress of T6 is ...

The aluminum container manufacturing industry first originated in some developed capitalist countries in Europe and the United States. In the early eighties, these labor-intensive processing and manufacturing industries have been transferred to developing countries, and then the manufacturing center transferred to South Korea. In the mid-nineties, because of the impact of the Asian financial turmoil, South Korea' ...

Low stocks have limited impact in the off-season, and aluminum prices are expected to fluctuate strongly in August Source: SMM SMM News on August 4th: Aluminum prices have almost risen continuously since the beginning of the second quarter. The gravity center of aluminum futures in July has continued to move upward. Although July 16 recorded the largest daily decline since April, it is supported by fundamentals. ...

6061 T6 Aluminum Sheet is an aluminum sheet product that is very versatile and has a wide range of applications. 6061 Aluminum sheet is made from one of the most widely used heat treatable aluminum alloys. This sheet has excellent corrosion resistance, good workability and good machinability. 6061 sheet applications include a wide variety of products from medical assemblies, aircraft construction to structural co ...

The 7000 series aluminum sheet is the best series of eight aluminum alloy series, representing the highest level of current aluminum sheet production process. The most representative product of the 7000 series aluminum can be said 7075 aluminum sheet, which has high strength and high hardness. The main alloying elements of the 7000 series aluminum sheet are zinc and magnesium. As a cold forging alloy, the stre ...

Aluminum 6061 T4 Sheet is solution heat treated and naturally aged giving it slightly lower tolerance accuracy than Aluminum 6061 T6, which undergoes artificial aging. T4 is also slightly less expensive than T6 and has a slightly lower ultimate tensile strength and yield strength, with a higher elongation percentage, which increases the formability of the T4 temper. Aluminum sheet 6061 T4 is also cost friendlier ...